Method adopting stereoscopic metal belt technology for producing thermal pressure-sensitive resistor and products thereof

A technology of piezoresistor and thermistor chip, applied in piezoresistor cores, piezoresistors, resistors, etc., can solve the problems of low work efficiency, large space requirement, easy deformation of lead wires, etc., and achieve work efficiency Improve welding efficiency and solve the effect of easy slag drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

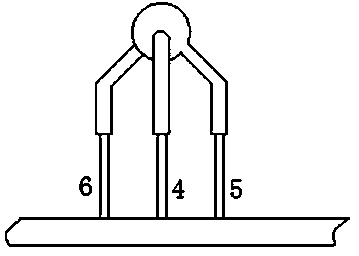

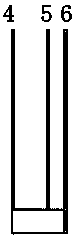

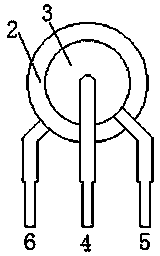

[0038] Embodiment 1 of the present invention: the three-dimensional metal strip process is used to produce thermal varistors, and the three pins used for welding the thermal varistors are made of the same tinned steel strip (hereinafter referred to as the steel strip). The thickness of the three pins is 0.3mm, and the three pins are fixed on the steel strip to form a three-dimensional structure, that is, the horizontal spacing and longitudinal structure of the three pins are completely consistent with the spatial structure of the pins of the finished thermal varistor, such as figure 1 , figure 2 As shown; directly plug the three pins fixed on the steel strip with the thermistor chip and the varistor chip, so that each pin is in the corresponding position of the thermistor chip and the varistor chip, wherein, The common terminal pin is inserted between the thermistor chip and the varistor chip; while soldering the three pins, the thermistor chip and the varistor chip are sold...

Embodiment 2

[0040]Embodiment 2 of the present invention: the three-dimensional metal strip process is used to produce thermal varistors, and the three pins used for welding the thermal varistors are made of the same tinned iron strip (hereinafter referred to as the iron strip). The thickness of the varistor is 0.3mm, and the three pins are fixed on the iron strip to form a three-dimensional structure, that is, the horizontal spacing and vertical spacing of the three pins are completely consistent with the spatial structure of the pins of the finished thermal varistor. Figure 5 , Figure 6 As shown; first, eccentrically couple the thermistor chip and the piezoresistor chip, and reserve enough space on the piezoresistor chip for subsequent soldering of the common terminal pins, and then connect the three pins fixed on the iron strip The pins are inserted into the thermistor chip and the piezoresistor chip, so that each pin is in the corresponding position of the thermistor chip and the pie...

Embodiment 3

[0042] Embodiment 3 of the present invention: The three-dimensional metal strip process is used to produce thermal varistors, and the three pins used for welding thermal varistors are made of the same tinned copper strip (hereinafter referred to as copper strip). The thickness of the three pins is 0.3mm, and the three pins are fixed on the copper strip to form a three-dimensional structure, that is, the horizontal spacing and vertical spacing of the three pins are completely consistent with the spatial structure of the pins of the finished thermal varistor. Such as Figure 5 , Figure 6 As shown in the figure below; first, eccentrically couple the thermistor chip and the varistor chip, and reserve enough space on the varistor chip for subsequent soldering of the common terminal pins, and then connect the three pins fixed on the copper tape The pins are inserted into the thermistor chip and the piezoresistor chip, so that each pin is in the corresponding position of the thermi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com