Corrugated monofilament type steel wire for cutting

A monofilament type, corrugated technology, applied in the field of corrugated monofilament type steel wire for cutting, can solve the problem of the performance of the abrasive carrier, and achieve the effects of reducing wear, improving efficiency, and high-precision surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

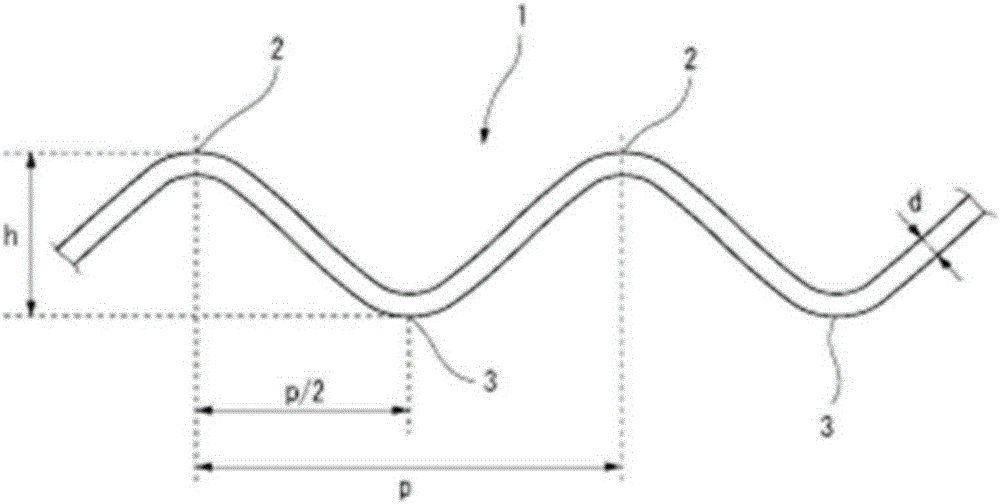

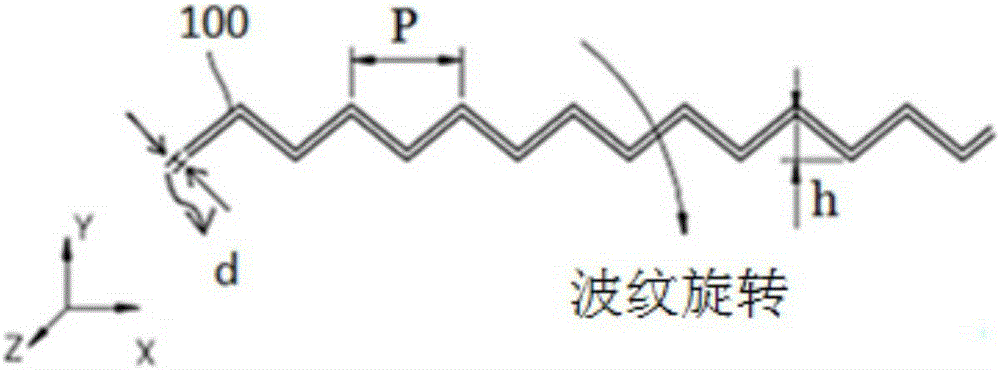

Embodiment 1

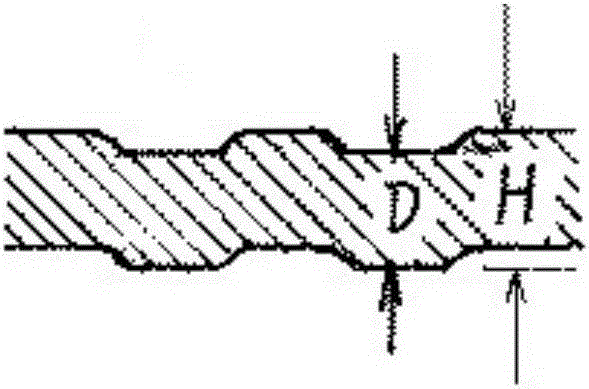

[0056] The wirerod with a carbon content of 0.70-1.05% and a diameter of 5.5 mm is drawn twice, followed by heat treatment and brass plating, and finally drawn to a diameter of 0.100 mm to prepare a monofilament steel wire. Next, using a corrugation device, corrugated monofilament steel wire for cutting was produced by giving corrugation to two planes of the monofilament steel wire that was finally drawn and not provided with corrugation, and making εxP 0.1 and εxd 0.15h. The obtained corrugated monofilament steel wire for cutting was evaluated for its wire diameter, corrugation period, elongation, and elongation at break, and the results are shown in Table 1 below.

[0057] On the other hand, after cutting a silicon ingot with a diameter of 150 mm using a slurry made of silicon carbide, the physical properties and productivity of the wafer were evaluated by the following methods and the results are listed in Table 1 below. .

[0058] [Physical property evaluation method]

...

Embodiment 2

[0064] For the wire rod (wirerod) with a carbon content of 0.70-1.05% and a diameter of 5.5 mm, the drawing process is performed twice, followed by heat treatment and brass plating, and finally drawn to 0.115 mm to prepare a monofilament type steel wire. When giving corrugation, Except that εxP was set to 0.5 and εxd was set to 0.32h, the rest was carried out in the same manner as in Example 1 to produce corrugated monofilament steel wires for cutting, and the physical properties were evaluated and listed in Table 1 below.

Embodiment 3

[0066] Except for setting εxP to 1.0 and εxd to 0.26h, the same procedure as in Example 2 was carried out to produce a corrugated monofilament steel wire for cutting, and various physical properties were evaluated and listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com