Method for preparing ZSM-35 molecular sieve

A technology of ZSM-35 and molecular sieve, which is applied in iron conglomerate crystalline aluminum silicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of environmental pollution and high synthesis cost of molecular sieve, achieve good technical effect and reduce synthesis cost , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

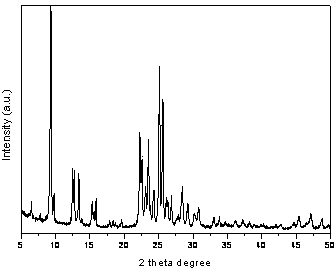

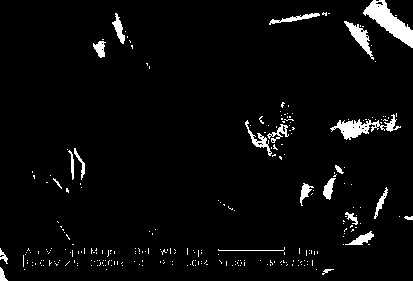

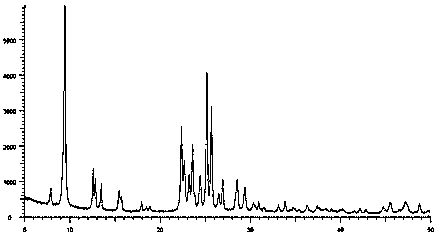

Image

Examples

Embodiment 1

[0039] [Example 1] Synthetic directing agent

[0040] Press 1Al 2 o 3 :29.8SiO2 2 :4.33M 2 O:12.07R:1523H 2 O ratio, dissolve 1.03 grams of sodium aluminate in 76.08 grams of water, add 0.99 grams of potassium hydroxide to dissolve, add 3.00 grams of template agent ethylenediamine, stir well, add 18.51 grams of 40% silica sol, stir for 1 hour, put In an oven at 40°C, let stand for three days.

[0041]

Embodiment 2

[0042] [Example 2] synthetic directing agent

[0043] Press 1Al 2 o 3 :30.02SiO2 2 :3.03M 2 O:20.08R:2015H 2 O ratio, dissolve 1.52 grams of aluminum sulfate in 112.50 grams of water, add 1.00 grams of sodium hydroxide to dissolve, add 8.21 grams of template agent cyclohexylamine, stir evenly, add 18.60 grams of 40% silica sol, stir for 1 hour, put in 60 ℃ oven for three days.

[0044]

Embodiment 3

[0045] [embodiment 3] synthetic directing agent

[0046] Press 1Al 2 o 3 :60.03SiO2 2 :6.01M 2 O:18.33R:999.4H 2 O ratio, dissolve 1.37 grams of sodium aluminate in 69.20 grams of water, add 2.67 grams of sodium hydroxide to dissolve, add 10.00 grams of template agent pyridine, stir evenly, add 45.60 grams of water glass, stir for 1 hour, and put it in an oven at 80°C , let stand for two days.

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com