Orientated film material, preparation method thereof, orientated film and preparation method thereof

An alignment film and host material technology, applied in the field of liquid crystal display devices, can solve the problem that the controllability of the pretilt angle cannot be realized in a large range, and achieve the effect of high pretilt angle and improved thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] As another aspect of the present invention, the preparation method of described alignment film material is provided, and this preparation method comprises the following steps:

[0045] dissolving carborane cage modified organic compound nanoparticles in an organic solvent;

[0046] mixing the solution of the carborane cage modified organic nanoparticles with the precursor solvent of the main material of the alignment film to obtain a mixture;

[0047] The obtained mixture is mixed with the alignment film host material to obtain the alignment film material.

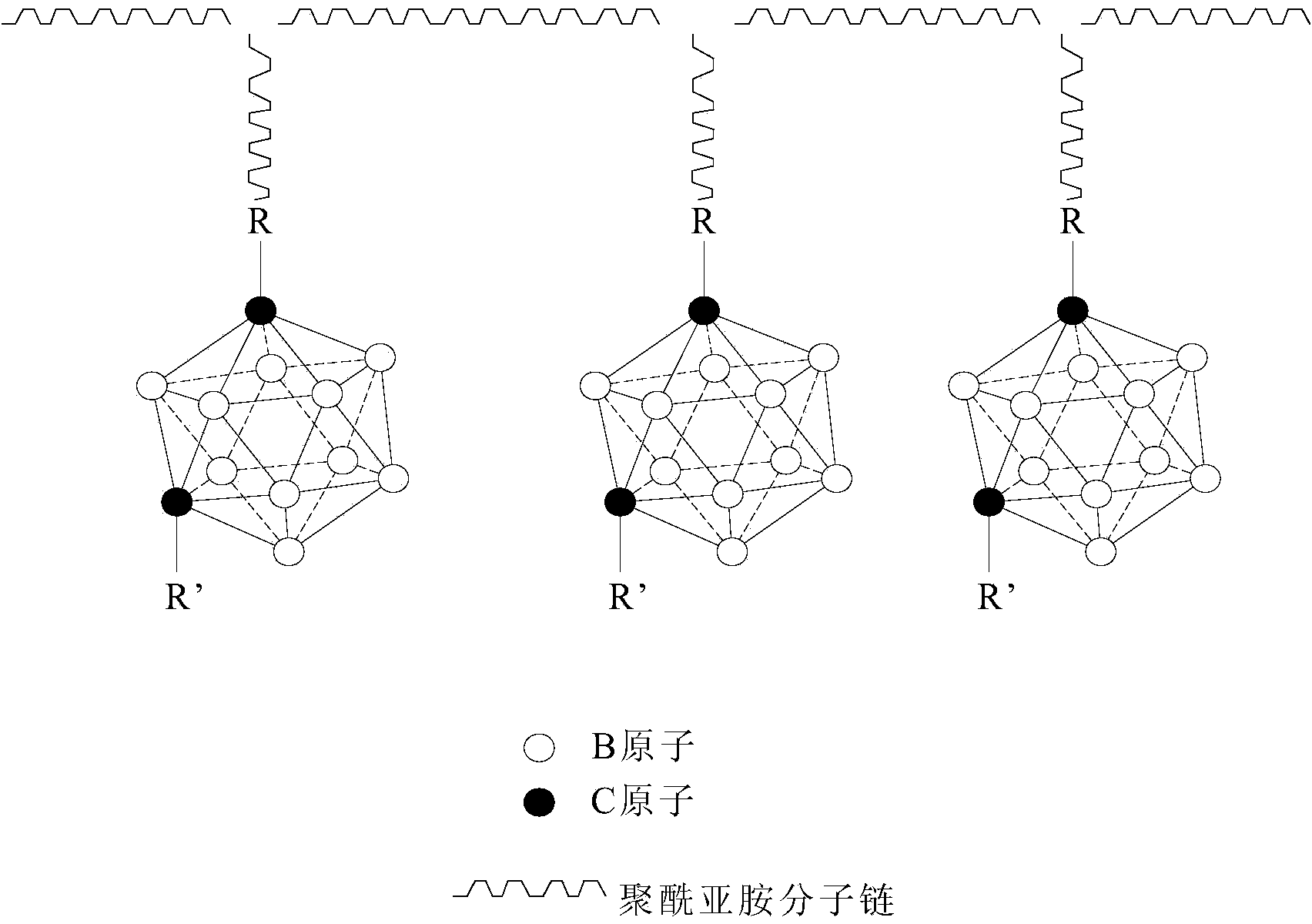

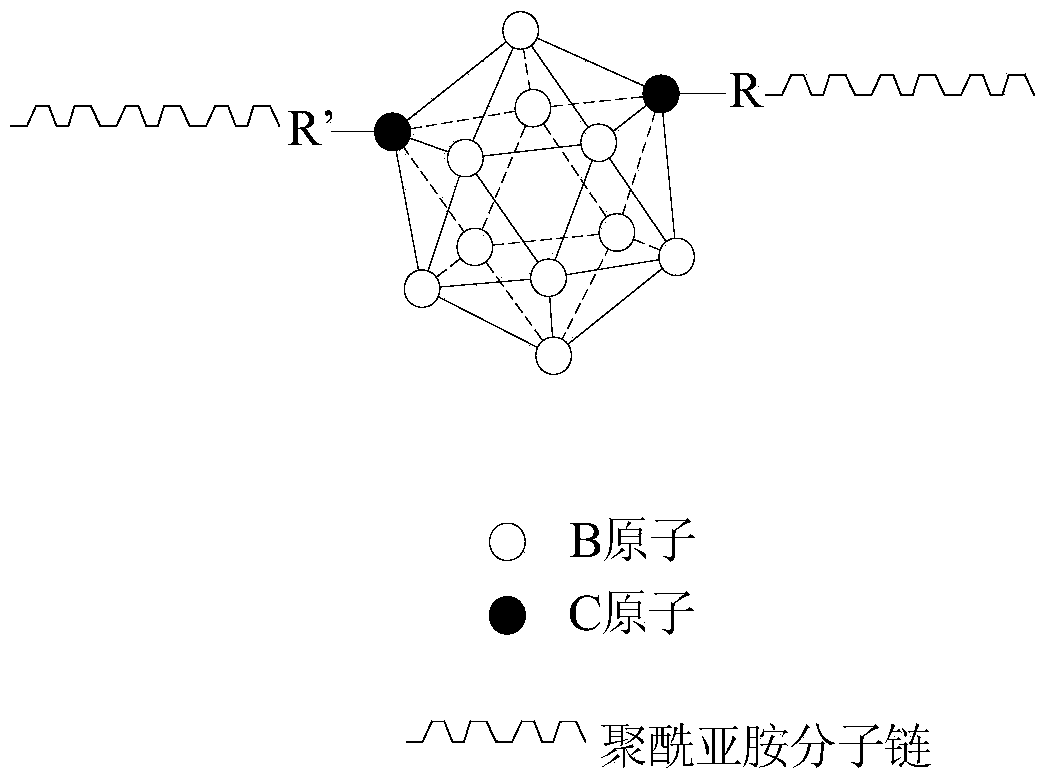

[0048] As another aspect of the present invention, an alignment film is provided, wherein the alignment film is obtained by curing the above-mentioned alignment film material provided by the present invention, and in the chemical structure of the alignment film, the carborane cage modification The groups R and / or R' in the molecular structure of the organic compound nanoparticles are combined on the molecular chain...

Embodiment 1

[0066] First, prepare the alignment film material according to the following steps:

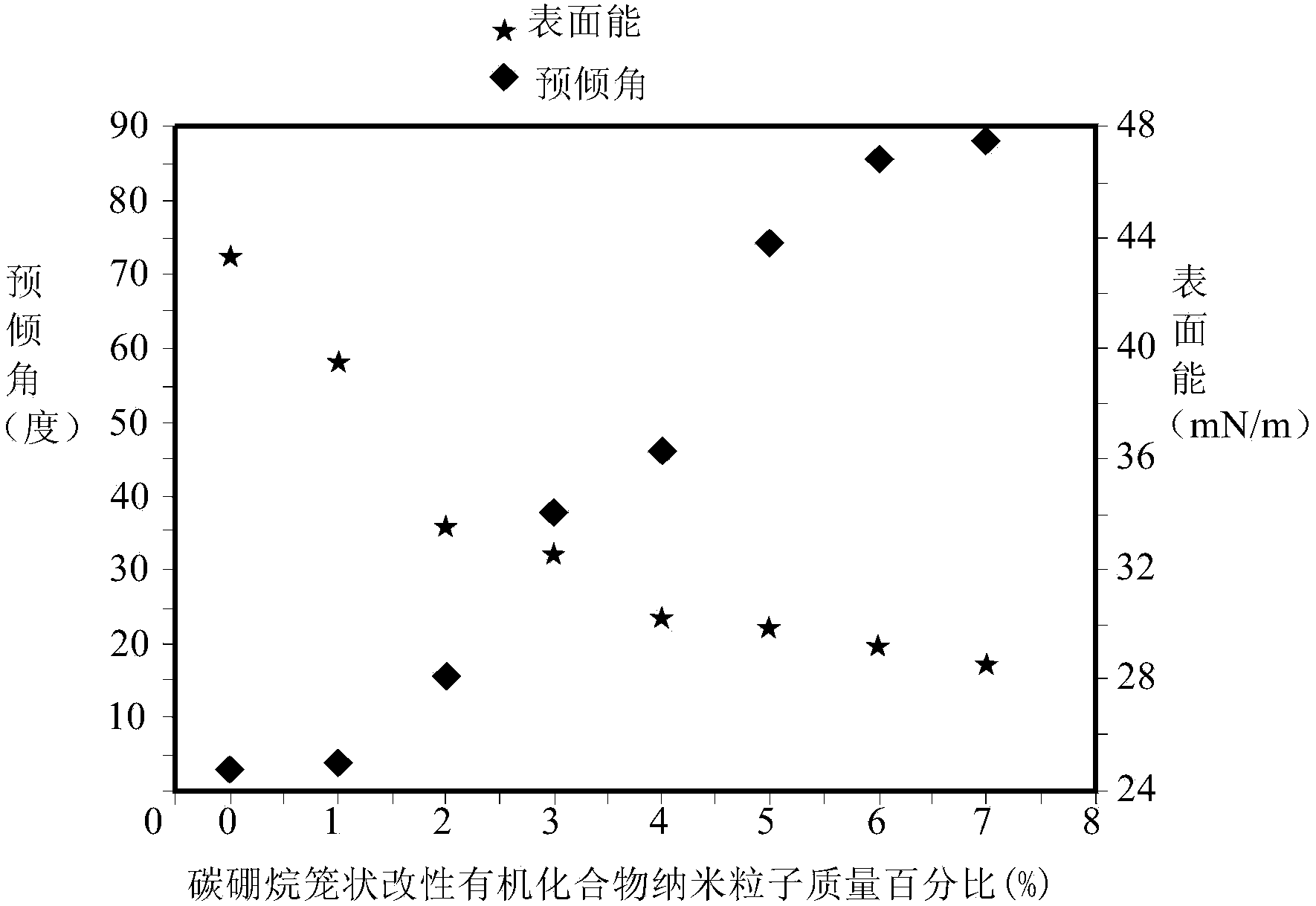

[0067] S1, dissolving 5 grams of carborane cage-shaped modified organic compound nanoparticles in 95 grams of NMP to form a 5%wt carborane cage-shaped modified organic compound nanoparticle solution, carborane cage-shaped modified organic compound nanoparticles The molecular structure of the particle is C2B10H12RR', where R and R' are -(CH2)n-CO-;

[0068] S2. Mix 100 grams of the solvent of the carborane cage modified organic nanoparticles with 100 grams of the precursor solvent of the main material of the oriented film to obtain a mixture. The precursor solvent can have the following components:

[0069] p-dihexylcyanopyromellitic anhydride and p-diaminobiphenyl NMP solution with a mass content of 7%, wherein the molar ratio of p-dihexycyanopyromellitic anhydride to p-diamine is 1:1.05;

[0070] S3. Mix 200 grams of the mixture obtained in step S2 with 100 grams of the alignment film main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com