Environment-friendly PU matte varnish

A clear topcoat, matte technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of uneven gloss, poor transparency of recoating, loss of wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

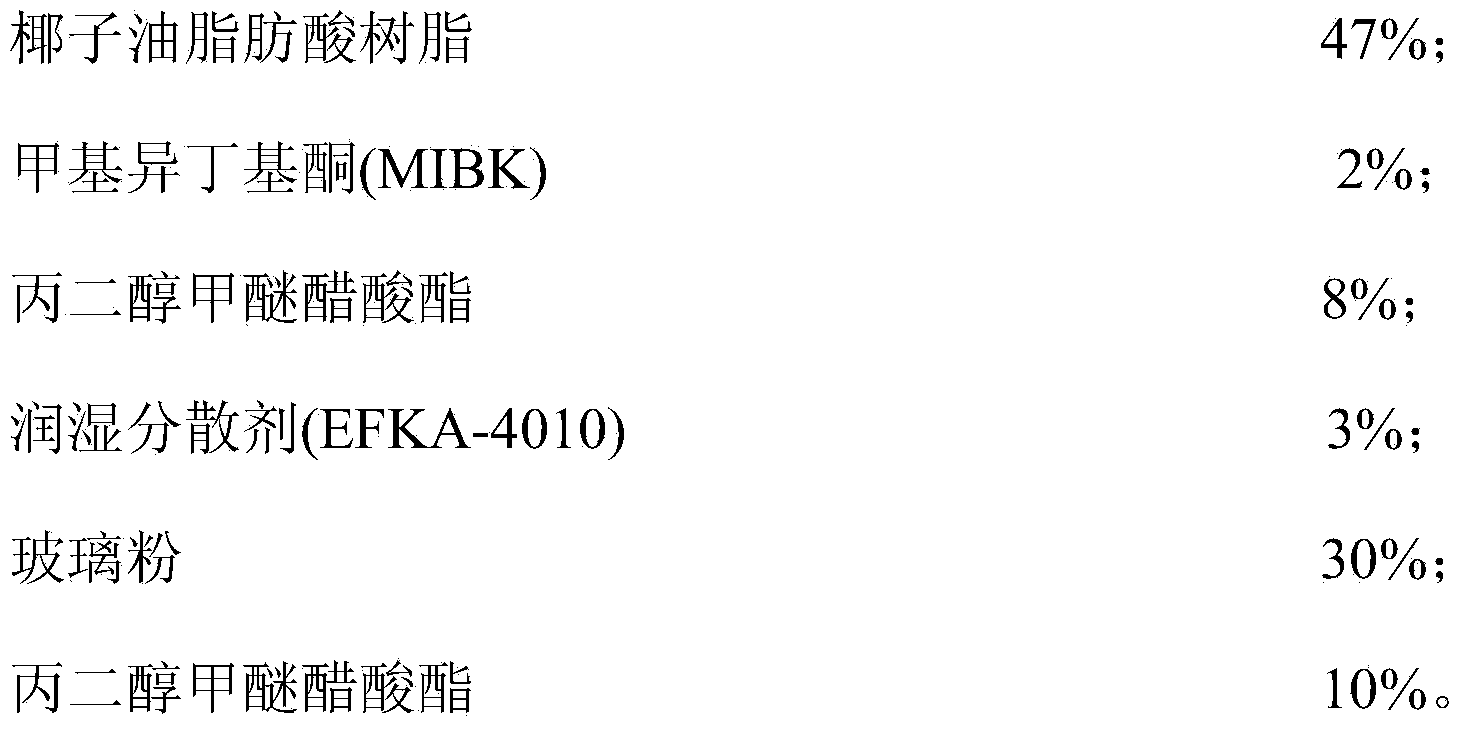

[0053] 1) Prepare 30% glass paste

[0054]

[0055] Put in coconut oil fatty acid resin, methyl isobutyl ketone (MIBK), propylene glycol methyl ether acetate and wetting and dispersing agent (EFKA-4010), stir evenly at 700 rpm, put in glass powder, and use part of propylene glycol Clean the side of the tank with methyl ether acetate, disperse until the fineness is ≤25μm at 1200 rpm, stop the machine and add the remaining propylene glycol methyl ether acetate, stir evenly at 650 rpm, and filter through a 120-mesh filter to obtain 30 % glass pulp, stand-by, pay attention to stirring evenly before adding.

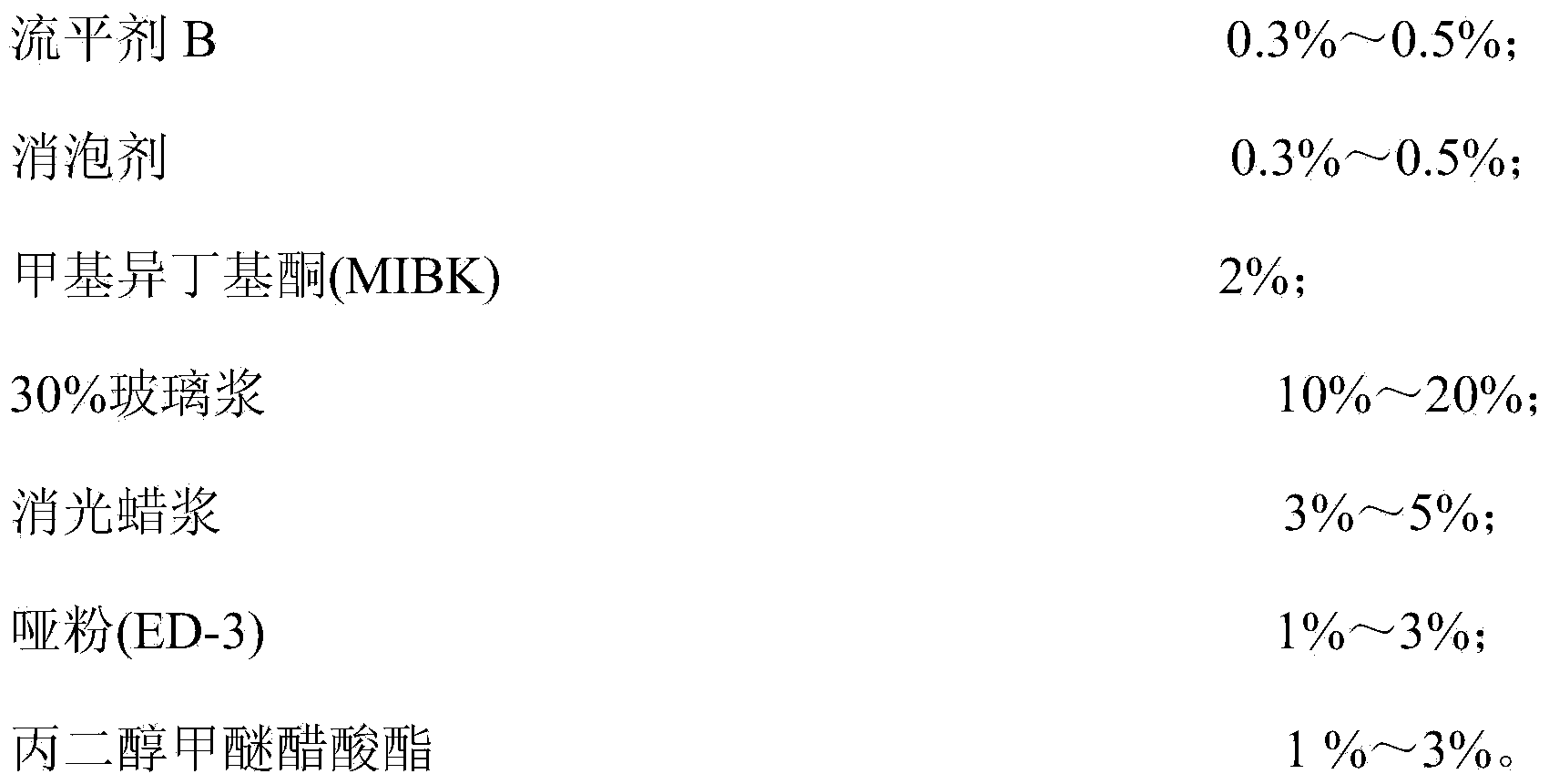

[0056] 2) Preparation of paint main agent components:

[0057]

[0058] The preparation method is:

[0059] Add fatty acid short oil alkyd resin, thixotropic resin, and xylene into the dispersing tank, stir at a low speed of 700 rpm for 10 minutes until fully uniform, and add wetting and dispersing agent, leveling agent A, flow Leveling agent B, defoamer, methyl isobu...

Embodiment 2

[0068] 1) Prepare 30% glass paste

[0069]

[0070]

[0071] Put in coconut oil fatty acid resin, methyl isobutyl ketone (MIBK), propylene glycol methyl ether acetate and wetting and dispersing agent (EFKA-4010), stir evenly at 700 rpm, put in glass powder, and use part of propylene glycol Clean the side of the tank with methyl ether acetate, disperse until the fineness is ≤25μm at 1200 rpm, stop the machine and add the remaining propylene glycol methyl ether acetate, stir evenly at 650 rpm, and filter through a 120-mesh filter to obtain 30 % glass pulp, stand-by, pay attention to stirring evenly before adding.

[0072] 2) Preparation of paint main agent components:

[0073]

[0074] The preparation method is:

[0075] Add fatty acid short oil alkyd resin, thixotropic resin, and xylene into the dispersing tank, stir at a low speed of 750 rpm for 10 minutes until fully uniform, and add wetting and dispersing agent, leveling agent A, flow Leveling agent B, defoamer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com