Horizontal drainage consolidation method through blow filling of soft soil

A horizontal drainage and soft soil technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of poor drainage consolidation effect, hindered drainage, unevenness, etc., to speed up the formation of soil structure and avoid The slowness of negative pressure transmission, the effect of saving electricity and engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

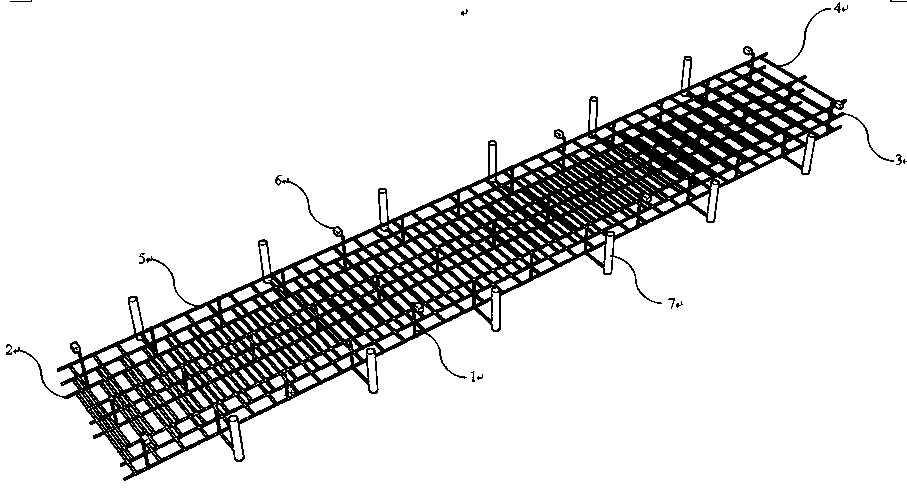

[0032] Embodiment 1, see attached Figure 1~4 , attached Figure 9 .

[0033] A horizontal drainage consolidation method for dredging soft soil, the method is as follows:

[0034] (1) In the dredging filling area, divide into zones according to the width of 100m, and there are several zones

[0035] Area;

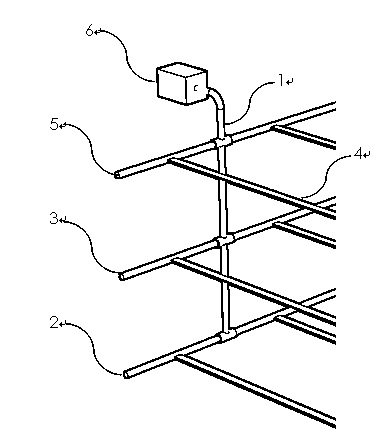

[0036] (2) On both sides of the zoning area, several vertical pipes 1 are arranged vertically on the ground plane, and the bottom ends of the vertical pipes on both sides are respectively connected to the vertical horizontal pipes 2; the distance between the vertical pipes is 4m; the pipe diameter is 8cm ;

[0037] (3) In the zoning area, there are several flexible horizontal drainage boards 4 arranged horizontally and horizontally, and the two ends of the horizontal drainage boards are respectively connected with the longitudinal horizontal pipes 2 on both sides; the distance between the drainage boards is 1.5m;

[0038] (4) Dredge soft soil in the zoning area; th...

Embodiment 2

[0045] Embodiment 2, see attached Figure 5 .

[0046] A horizontal drainage consolidation method for dredging soft soil, wherein the two adjacent layers of the drainage board 4 are equidistantly and laterally arranged. That is to say, on the cross-section of the soil layer, the points of the drainage boards can be arranged in a horizontal and vertical grid, or in a staggered rhombus or regular triangle (also known as a plum blossom) arrangement. The equidistant dislocation of the drainage board can make the drainage uniform, which is beneficial to improve the drainage consolidation effect in the middle area of the drainage board.

Embodiment 3

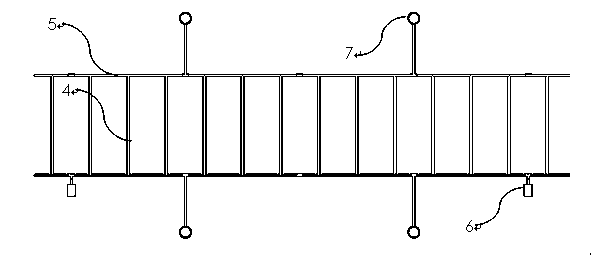

[0047] Embodiment 3, see attached Figure 6~7 .

[0048] A horizontal drainage consolidation method for dredging soft soil, in which the unit area is divided into unit areas with a length of 100 m along the vertical pipe arrangement direction in the zoning area; the vertical horizontal pipes 2 at the ends of each layer of the unit area pass through the horizontal 8 connected; the horizontal plane of the unit area is rectangular or square; there are several unit areas; soft soil is dredged in the unit area.

[0049] Vertical drainage boards 9 are arranged across the horizontal drainage boards 4 arranged horizontally on each layer, and the two ends of the longitudinal drainage boards 9 are connected to the horizontal horizontal pipes 8 . In this way, the vertical and horizontal bidirectional arrangement of the drainage board can be formed, which can significantly reduce the drainage time and shorten the construction period.

[0050] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com