Piston-type high-temperature heat pump device for waste heat recovery

A high-temperature heat pump and waste heat recovery technology, which is applied to the operation mode of the machine, heating and cooling combination, lighting and heating equipment, etc., can solve the problems of incomplete improvement, aggravate the greenhouse effect, reduce heating energy consumption, etc., and achieve saving Effects of primary energy, improvement of working environment and reduction of equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

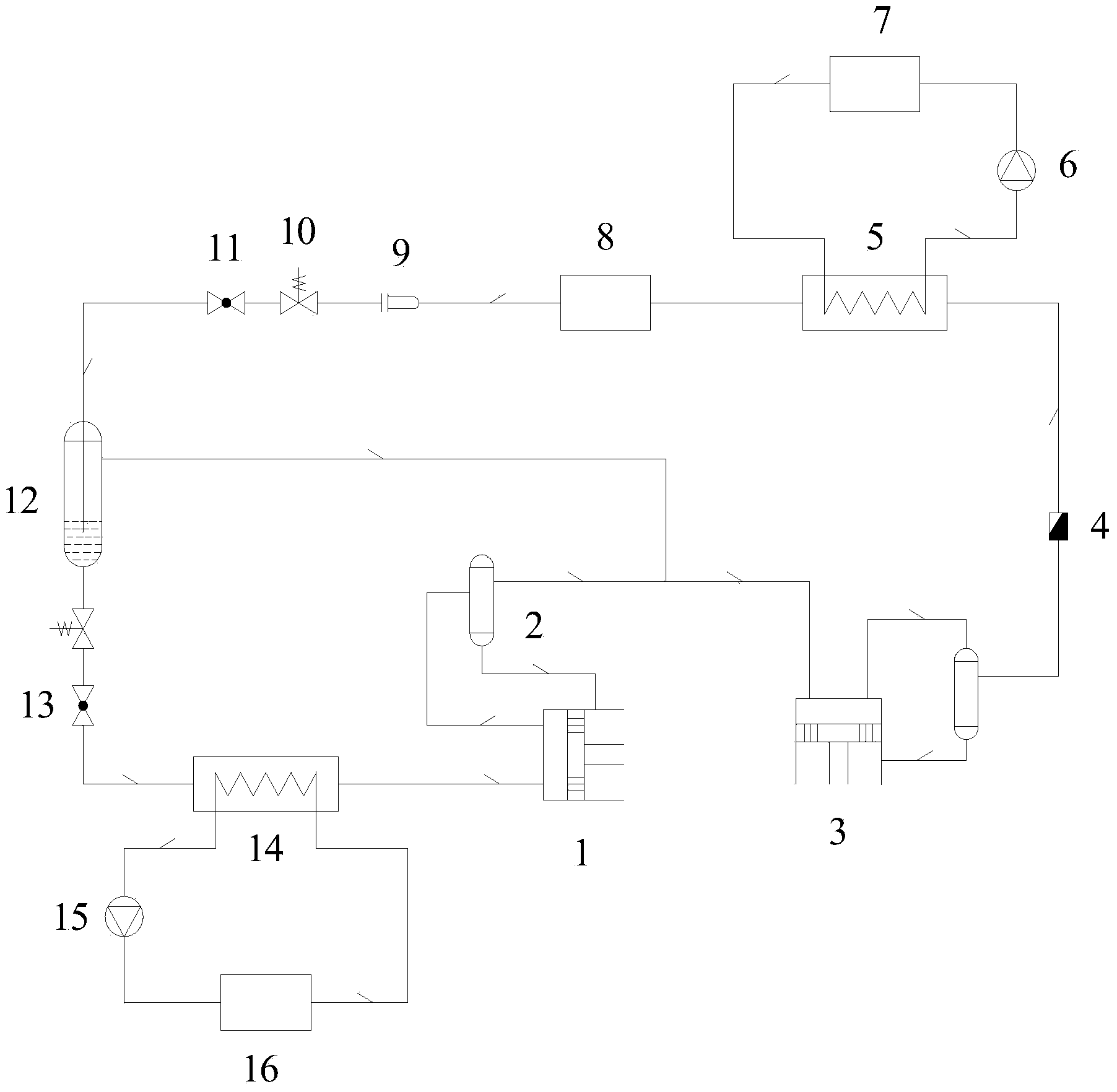

[0017] As shown in Figure 1, a piston-type high-temperature heat pump device for waste heat recovery is composed of three parts: a high-temperature heat pump unit, a high-temperature hot water circuit and a low-temperature cold water circuit; the high-temperature heat pump unit includes a low-pressure compressor 1, Oil separator 2, high pressure compressor 3, one-way valve 4, condenser 5, high temperature liquid receiver 8, filter drier 9, solenoid valve 10, primary expansion valve 11, gas-liquid separator 12, secondary expansion valve 13. Evaporator 14; the high-temperature hot water circuit includes a condenser 5, a hot-end water pump 6, and a hot-end heat exchanger 7; the low-temperature cold water circuit includes an evaporator 14, a cold-end water pump 15, and a cold-end heat exchanger 16.

[0018] Among them, the outlets of the low-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com