Energy-saving industrial energy station utilizing waste heat recovery and clean energy and operation control method

A technology of clean energy and waste heat recovery, applied in the energy industry, heating methods, household heating, etc., can solve problems such as insufficient power supply, high power consumption, waste of resources, etc., to reduce energy use costs, reduce production and operation costs, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

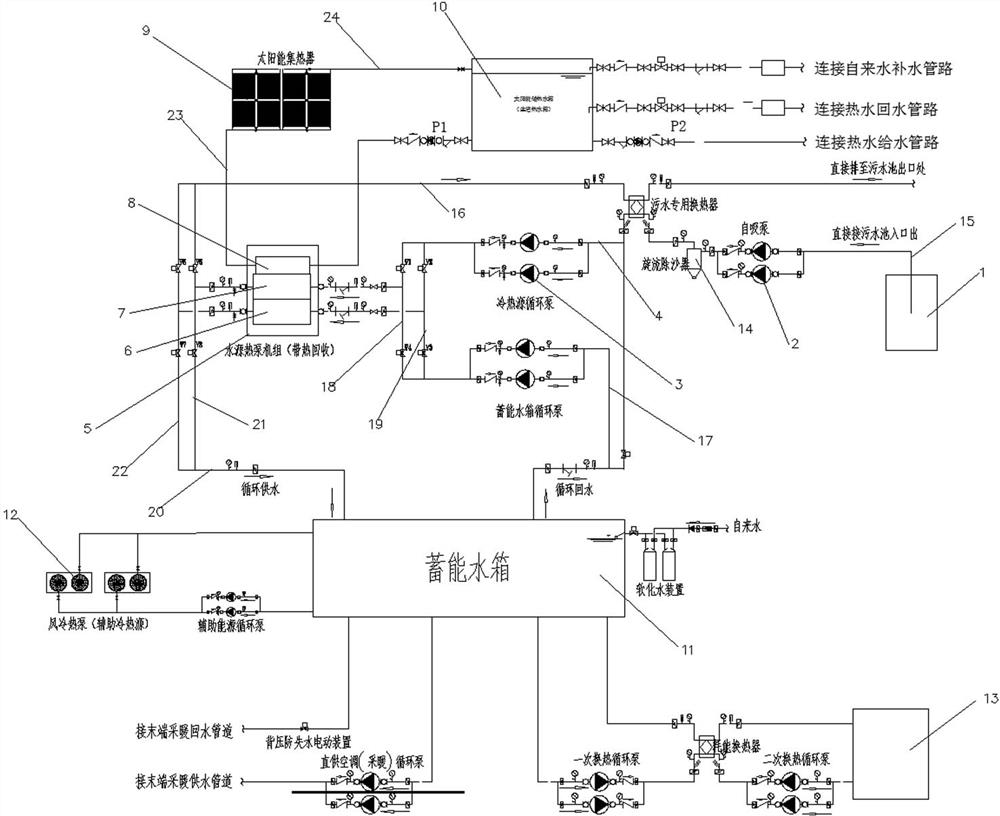

[0037] Such as figure 1 As shown, an energy-saving industrial energy station using waste heat recovery and clean energy, including sewage source heat pump system, auxiliary system, energy storage system and solar auxiliary heating system.

[0038] The sewage source heat pump system includes a sewage heat exchanger and a sewage pool 1. The sewage pool 1 is connected to the water inlet end of the sewage heat exchanger through a sewage pipe 15 equipped with a self-priming pump 2. The sewage pipe 15 is provided with a swirling sand removal Device 14. The outlet of the sewage heat exchanger is connected to the outlet of the sewage tank 1, and the refrigerant inlet and outlet of the sewage heat exchanger are respectively connected to the liquid inlet pipe 16 and the liquid return pipe 4 equipped with the cold and heat source circulation pump 3. A shunt pipe I21 and a shunt pipe II22 are connected in parallel on the liquid pipe 16, and a return pipe I18 and a return pipe II19 are co...

Embodiment 2

[0050] An operation control method of an energy-saving industrial energy station utilizing waste heat recovery and clean energy, including a summer operation method and a winter operation method;

[0051] Summer run method, including the following steps:

[0052] (1) Turn on the sewage source heat pump system for refrigeration, and start the energy storage system for energy storage:

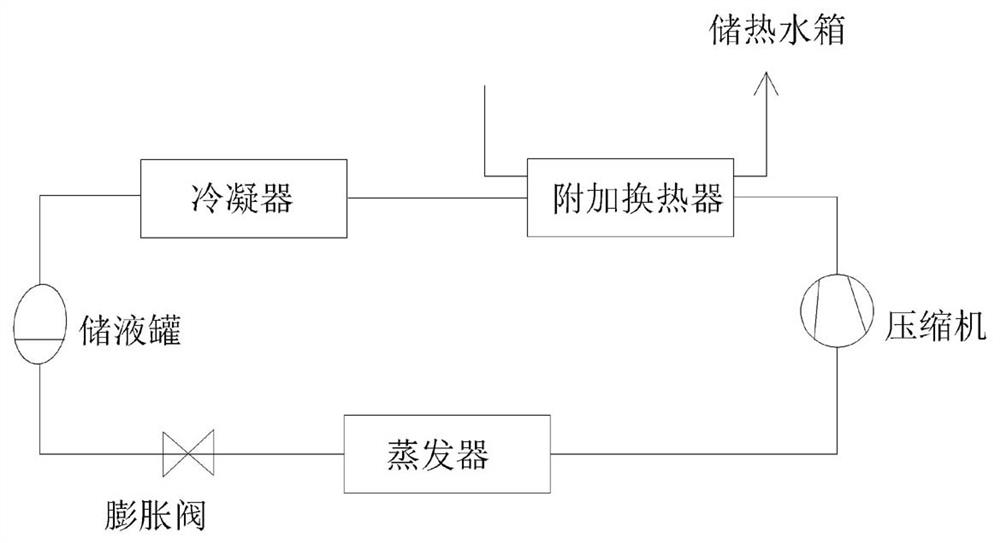

[0053] ① Open the electric valve V1 and the electric valve V5, and the refrigerant entering the condenser 7 performs heat exchange with the sewage in the sewage tank 1 through the heat exchanger Ⅰ, so that the temperature of the refrigerant is lowered;

[0054] ② Open the electric valve V3 and the electric valve V7, the tap water entering the energy storage water tank is cooled by the evaporator 6 and then returns to the energy storage water tank, and the energy storage water tank stores energy as a cold source;

[0055] (2) Auxiliary system refrigeration: the air-cooled heat pump unit 12 is tur...

Embodiment 3

[0060] An operation control method of an energy-saving industrial energy station using waste heat recovery and clean energy. The winter operation method is as follows: in winter, the heat load of the air conditioner is low, but the heating load is large, and the sewage source heat pump system and the solar auxiliary heating system are turned on during the day for heating. and production water heating, and turn on the auxiliary system and energy storage system for heating at night.

[0061] The specific winter operation method includes the following steps:

[0062] (1) Turn on the sewage source heat pump system for heating, and at the same time start the energy storage system for energy storage:

[0063] ① Open the electric valve V2 and the electric valve V6, and the refrigerant entering the evaporator 6 exchanges heat with the sewage in the sewage tank 1 through the heat exchanger Ⅰ, so that the temperature of the refrigerant rises;

[0064] ②Open the electric valve V4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com