Emulsion composition, and composition containing same

A composition and emulsion technology, applied in the formulation of perfume preparations, food ingredients as emulsifiers, medical preparations containing active ingredients, etc., can solve the problems of reduced transparency, reduced transparency of emulsified fragrances, poor emulsification stability, etc. problem, achieve high dispersion or solubility, inhibit turbidity or sedimentation, and excellent emulsification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

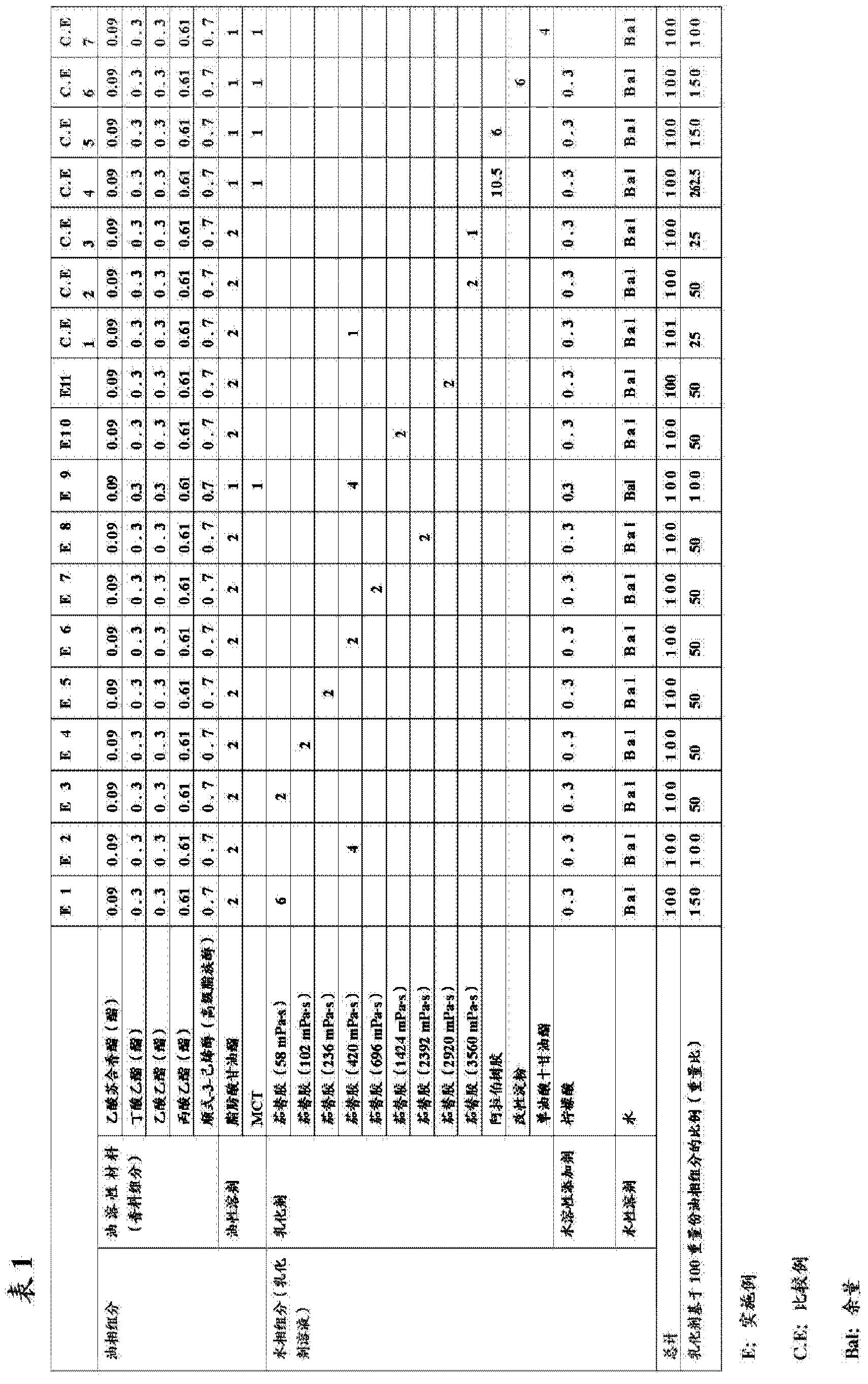

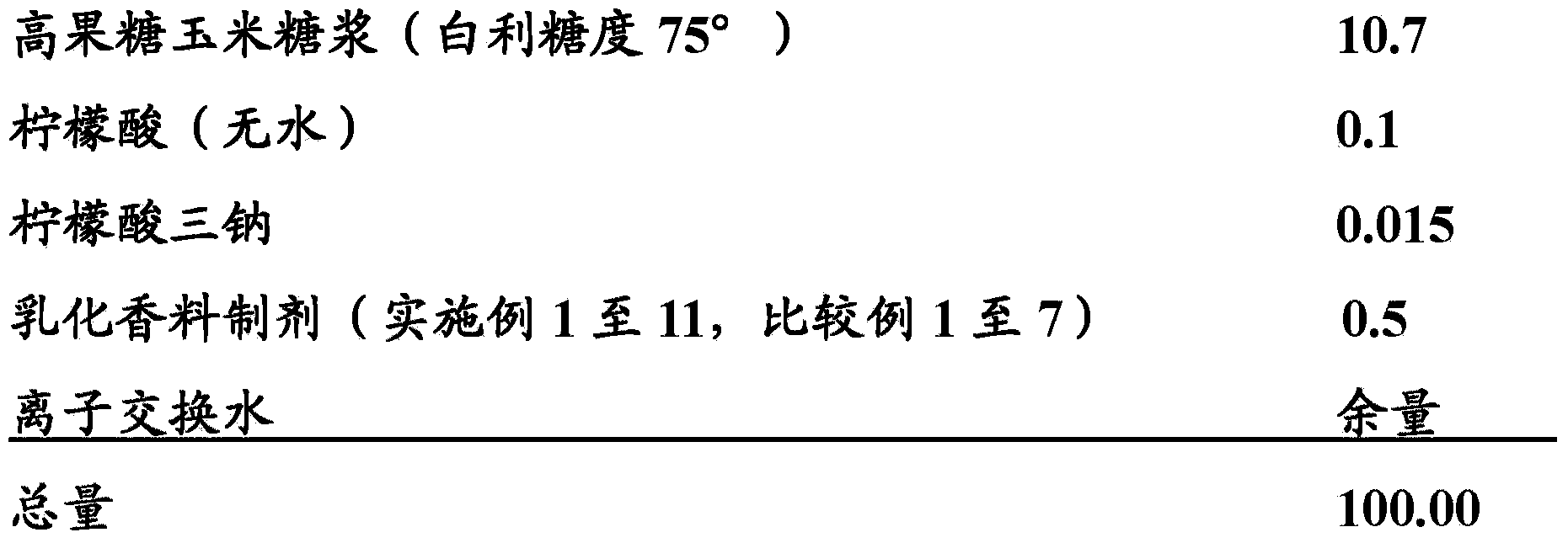

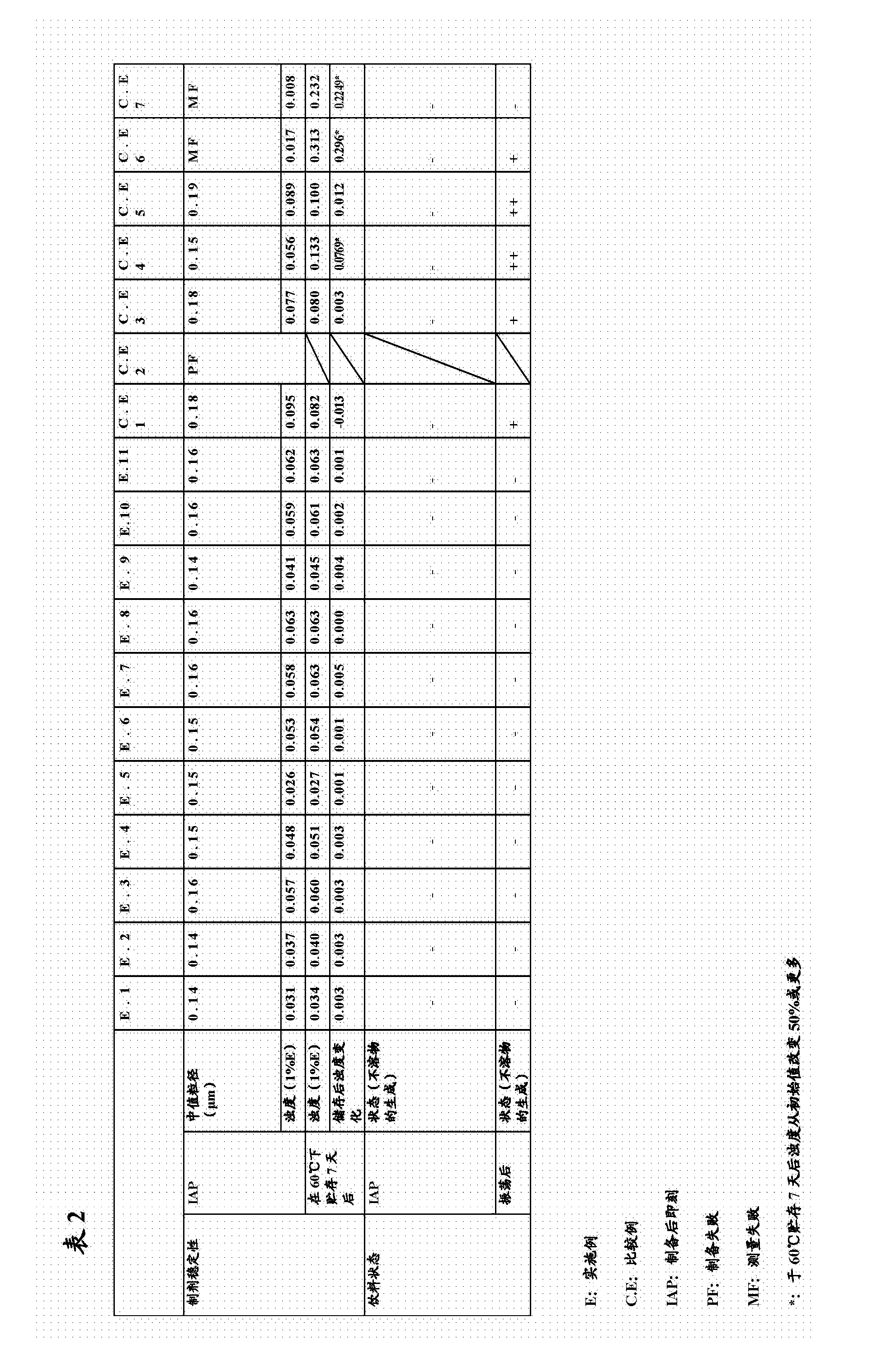

[0132] According to the formula shown in Table 1, various types of gum ghatti, gum arabic or decaglyceryl monooleate were used as emulsifiers to prepare emulsified fragrance compositions (emulsified fragrance preparations) (Examples 1 to 11, Comparative Example 1 to 7).

[0133] For each emulsified fragrance composition thus prepared, the median diameter (μm) of the oil phase particles and the turbidity (1%E) immediately after preparation, and the turbidity (1%E) after storage at 60° C. for 7 days were measured. %E), thereby evaluating the formulation stability of the composition. In addition, by combining these emulsified flavor compositions in potable water to prepare beverages, the state of the beverage immediately after preparation (the amount of insoluble matter produced) and the state of the beverage after shaking were visually observed to evaluate the composition's Solubility and stability in water.

[0134] (1) Method for preparing emulsified fragrance composition ...

experiment example 2

[0164] According to the formulation shown in Table 3, emulsified pigment compositions (emulsified pigment preparations) were prepared by using gum ghatti, gum arabic, β-pectin or modified starch as an emulsifier (Examples 12 to 16, Comparative Example 8 to 14). Regarding the thus obtained emulsified dye composition, its formulation stability was evaluated in the same manner as in Experimental Example 1. In addition, beverages were prepared by using these emulsified coloring compositions, and the storage stability of the beverage was evaluated by measuring the generation of suspended matter in the beverage immediately after preparation and in the beverage after shaking in the same manner as in Experimental Example 1.

[0165] (1) Method for preparing emulsified pigment composition

[0166] An oil-soluble material (pigment component) and an oily solvent (medium-chain triglyceride [MCT]) were uniformly mixed in the amounts shown in Table 3 each. The mixture was then added to ...

experiment example 3

[0188] According to the formula shown in Table 5, an emulsified vitamin composition (emulsified vitamin preparation) was prepared using gum ghatti with a viscosity of 50 mPa s to 3000 mPa s or gum ghatti with a viscosity higher than 3000 mPa s as an emulsifier (implementation Examples 17 to 21, Comparative Examples 15 to 17). For the emulsified vitamin composition thus obtained, formulation stability was evaluated in the same manner as in Experimental Example 1. In addition, drinks were prepared using these emulsified vitamin compositions, and the storage stability of the drinks was evaluated by measuring the generation of suspended matter in the drinks immediately after preparation and in the drinks after shaking in the same manner as in Experimental Example 1.

[0189] (1) Method for preparing emulsified vitamin composition

[0190] Oil-soluble materials (fat-soluble vitamins: mixed tocopherols) and oily solvents (rapeseed oil, medium-chain triglycerides [MCT]) were unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com