Ultrasonic polishing method and polishing device using liquid to transmit megahertz vibration

A technology of vibration polishing and liquid transfer, applied in the field of ultrasonic polishing methods and polishing devices, which can solve problems such as changes in resonance frequency, achieve strong vibration absorption characteristics, strong penetrating ability, and expand the range of vibration utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

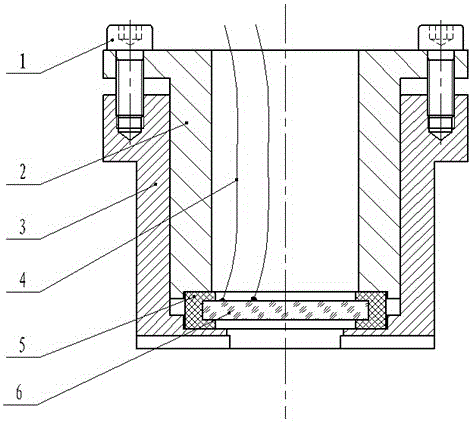

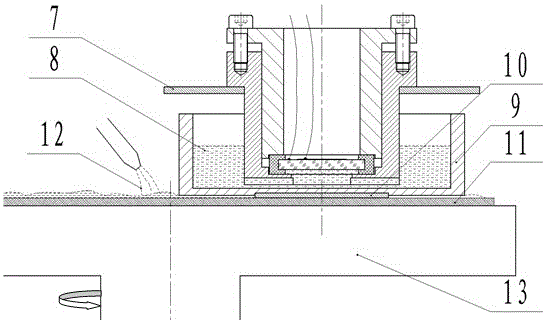

[0026] The ultrasonic polishing device that uses liquid to transmit megahertz vibration is composed of two parts: the ultrasonic vibration additional system and the polishing machine system. The vibration additional system includes three assemblies: vibrator and sealing device, coupling agent and vibration polishing tool. It consists of six parts (see figure 1 ); the polishing machine system is composed of the object to be polished (silicon wafer), polishing liquid, polishing pad, and polishing disc (see figure 2 ).

[0027] In the figure: 1-screw; 2-upper piece of compression device; 3-lower piece of compression device; 4-electric wire; 5-sealing ring; 6-disc piezoelectric vibrator; 7-horizontal cantilever support; 8-coupling agent; 9-vibration polishing tool; 10-silicon wafer; 11-polishing pad; 12-polishing liquid; 13-polishing disk.

[0028]The working surface of the disc piezoelectric vibrator of the present invention is immersed in the liquid environment. In order to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com