Special fertilizer suitable for film-mulched peanuts in Huang-Huai-Hai areas

A special fertilizer and peanut technology, which is applied in the field of organic-inorganic compound fertilizer manufacturing, can solve the problems of lack of research and development of special fertilizers, and achieve the effects of easy promotion, low production costs, and simple processing and application processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

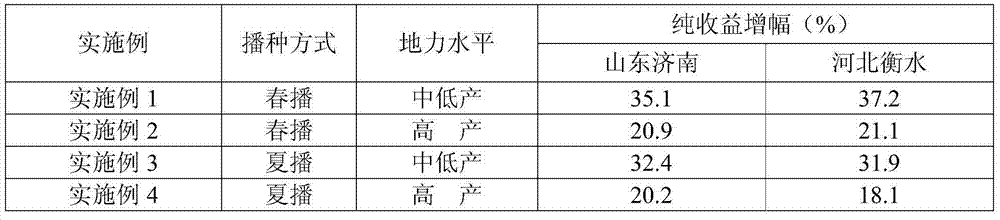

Examples

Embodiment 1

[0042] A special fertilizer for peanuts, with organic substrate, inorganic substrate, nitrogen fertilizer, potash fertilizer, active calcium slow-release phosphate fertilizer as basic raw materials, the mass parts of each component are: weathered coal 12 parts, bentonite 9 parts, urea 28 parts, active calcium slow-release fertilizer 28 parts of phosphate releasing fertilizer and 23 parts of potassium chloride.

[0043] The preparation method is as follows:

[0044] (1) Crush 30 parts by mass of peat, 10 parts by mass of sawdust, 10 parts by mass of bran, and 50 parts by mass of superphosphate to a particle diameter of 0.1-0.3 mm, and decompose with 3 parts by mass of ammonium bicarbonate and 0.3 parts by mass of straw The agent is evenly mixed and fermented, and the pile is turned over every 7 days. After 42 days of fermentation, it is dried to a water content of 30-40 wt% to obtain an active calcium slow-release phosphate fertilizer.

[0045] (2) The organic substrate, inorganic su...

Embodiment 2

[0048] A special fertilizer for peanuts, with organic substrate, inorganic substrate, nitrogen fertilizer, potash fertilizer, active calcium slow-release phosphate fertilizer as basic raw materials, and the mass parts of each component are: 23 parts of weathered coal, 7 parts of bentonite, 24 parts of urea, and active calcium 22 parts of phosphate releasing fertilizer and 24 parts of potassium chloride.

[0049] The preparation method is as follows:

[0050] (1) Crush 40 parts by mass of peat, 5 parts by mass of sawdust, 5 parts by mass of bran, and 50 parts by mass of calcium magnesium phosphate fertilizer to a particle diameter of 0.1-0.3 mm, and decompose with 4 parts by mass of ammonium bicarbonate and 0.2 parts by mass of straw The agent is evenly mixed and fermented, and the pile is turned over every 7 days. After 42 days of fermentation, it is dried to a water content of 30-40 wt% to obtain an active calcium slow-release phosphate fertilizer.

[0051] (2) The organic substrat...

Embodiment 3

[0054] A special fertilizer for peanuts. It uses organic substrate, inorganic substrate, nitrogen fertilizer, potash fertilizer, active calcium slow-release phosphate fertilizer as basic raw materials. The mass parts of each component are: weathered coal 24 parts, bentonite 7 parts, urea 20 parts, active calcium slow-release fertilizer 28 parts of phosphate releasing fertilizer and 21 parts of potassium chloride.

[0055] The preparation method is as follows:

[0056] (1) Crush 30 parts by mass of peat, 10 parts by mass of sawdust, 10 parts by mass of bran, and 50 parts by mass of superphosphate to a particle diameter of 0.1-0.3 mm, and decompose with 3 parts by mass of ammonium bicarbonate and 0.3 parts by mass of straw The agent is evenly mixed and fermented, and the pile is turned over every 7 days. After 42 days of fermentation, it is dried to a water content of 30-40 wt% to obtain an active calcium slow-release phosphate fertilizer.

[0057] (2) The organic substrate, inorganic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com