Sound insulation floor with micro-foaming plate as sound insulation cushion layer and construction method of sound insulation floor

A construction method and micro-foaming technology, applied in the direction of floors, sound insulation, building components, etc., can solve the problems of net height reduction and load increase, and achieve the effect of convenient laying, remarkable effect and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

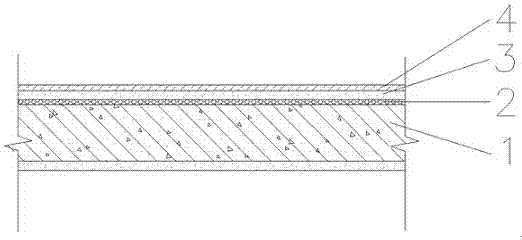

[0027] as attached figure 1 As shown in , the sound insulation floor of the present invention is composed of a reinforced concrete structure floor 1, a micro-foamed board sound insulation cushion layer 2, a cement mortar protective layer 3 and a surface layer material 4. The base layer is a reinforced concrete structure floor 1, and the middle layer is The micro-foamed board sound-insulating cushion 2 and the cement mortar protective layer 3, the cement-mortar protective layer 3 is located on the micro-foamed board sound-insulated cushion 2, and the upper layer is the surface layer material 4.

[0028] In this embodiment, the micro-foamed board sound insulation cushion in the sound-insulated floor is made of micro-foamed board material, which is a single-layer material made of polyvinyl chloride plastic (PVC), and the thickness of the material is 8 mm with a density of 380 kg / m 3 , the compressive strength is 200 KPa when the relative deformation is 1%, and the water absorpti...

Embodiment 2

[0036] as attached figure 1 As shown in , the sound insulation floor of the present invention is composed of a reinforced concrete structure floor 1, a micro-foamed board sound insulation cushion layer 2, a cement mortar protective layer 3 and a surface layer material 4. The base layer is a reinforced concrete structure floor 1, and the middle layer is The micro-foamed board sound-insulating cushion 2 and the cement mortar protective layer 3, the cement-mortar protective layer 3 is located on the micro-foamed board sound-insulated cushion 2, and the upper layer is the surface layer material 4.

[0037] In this embodiment, the sound insulation cushion layer of the micro-foamed board in the sound-insulated floor is made of micro-foamed board material, which is a multi-layer composite material with a thickness of 12 mm and a density of 300 kg / m 3 , the compressive strength is 100 KPa when the relative deformation is 1%, and the water absorption is 1%. The multi-layer composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com