High-density magnetic sensor device and magnetic induction method and preparation process thereof

A preparation process and magnetic sensing technology, applied in the direction of measuring devices, the size/direction of magnetic field, manufacturing measuring instruments, etc., can solve the problems that the three-axis sensor cannot be manufactured at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

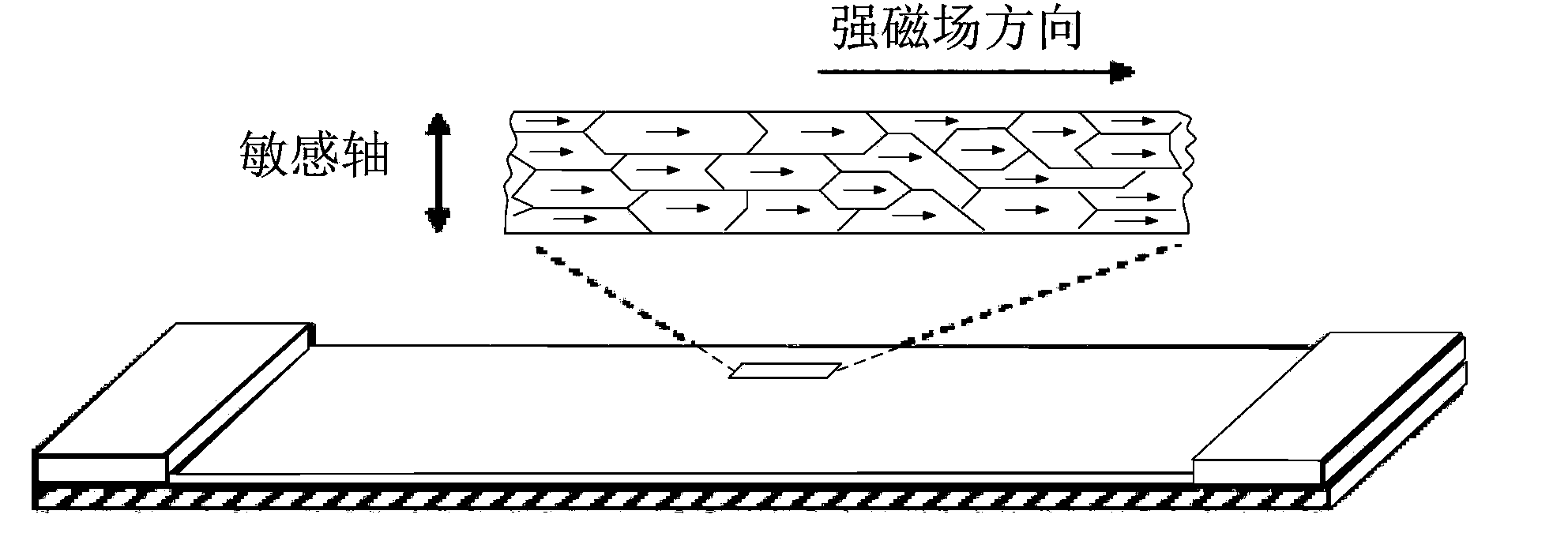

[0115] see Figure 6 , Figure 7 ,in, Figure 7 yes Figure 6 The projection along the A-A direction; the present invention discloses a high-density magnetic sensing device, which includes a Z-axis magnetic sensing component, and the Z-axis magnetic sensing component includes: a substrate 10, a magnetic conduction unit 20, an induction unit ; The substrate 10 may include CMOS peripheral circuits.

[0116] The surface of the substrate 10 has a dielectric layer, and a groove 11 is opened in the dielectric layer. The substrate is provided with one row or several rows of grooves. In this embodiment, one row of grooves includes several sub-grooves 11 .

[0117] The magnetic conduction unit 20 contains a magnetic material layer, such as Figure 6 As shown, the magnetically permeable unit 20 includes a first magnetically permeable part 21 and a second magnetically permeable part 22 respectively arranged on both sides of the groove 11; the main parts of the first magnetically per...

Embodiment 2

[0137] The difference between this embodiment and Embodiment 1 is that in this embodiment, multiple magnetic permeable structures can share the same groove; please refer to Figure 9The grooves 11 on the substrate 10 can be arranged in one or more rows, and one row of grooves 11 can be arranged as a long and narrow groove for shared use by multiple magnetic components.

Embodiment 3

[0139] The difference between this embodiment and Embodiment 1 is that in this embodiment, the Z-axis magnetic sensing component can be summarized as the third direction magnetic sensing component; the third direction magnetic sensing component includes at least a pair of A matched magnetic sensing module, the magnetic sensing module includes the magnetic conduction unit and the sensing unit; the third direction may be the Z-axis direction (vertical direction). After each pair of matching two magnetic sensing modules is set up, it can directly cancel the magnetic field signals of each pair of magnetic sensing modules in the first direction (such as the X-axis direction) or / and the second direction (such as the Y-axis direction) output.

[0140] The main parts of the first magnetically permeable part and the second magnetically permeable part of the magnetically permeable unit are arranged in a row of grooves; a row of grooves is composed of a long groove, or a row of grooves i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com