Ensilage method and silage material mixing device for anaerobic fermentation of energy herbs

An anaerobic fermentation and herbal plant technology, which is applied to silage material mixing device and herb silage field, can solve the problems of reducing enterprise profit rate and increasing operating cost, reducing silage cost, improving raw material gas production rate, and unique structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

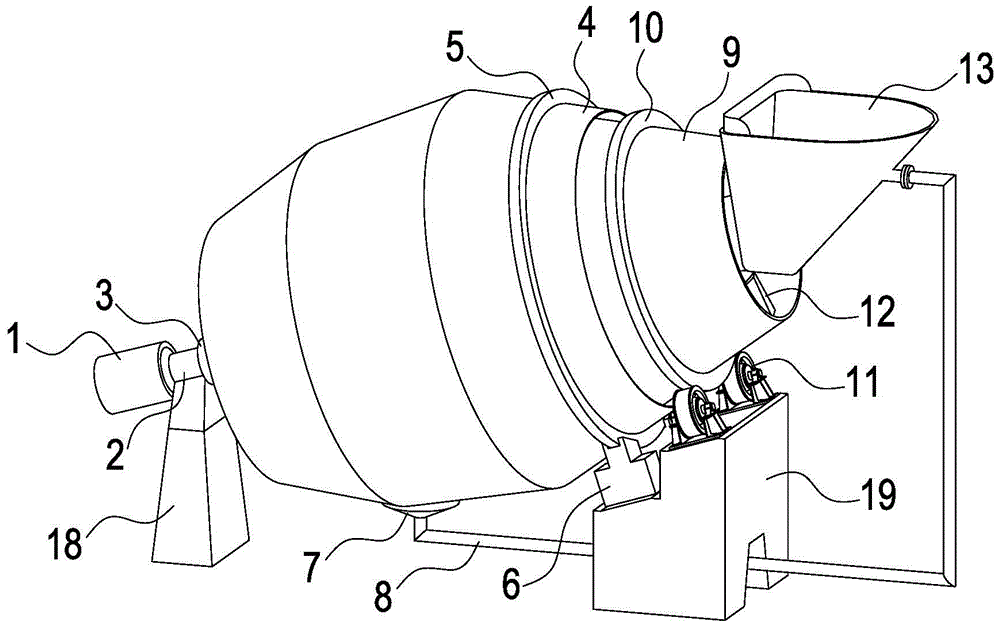

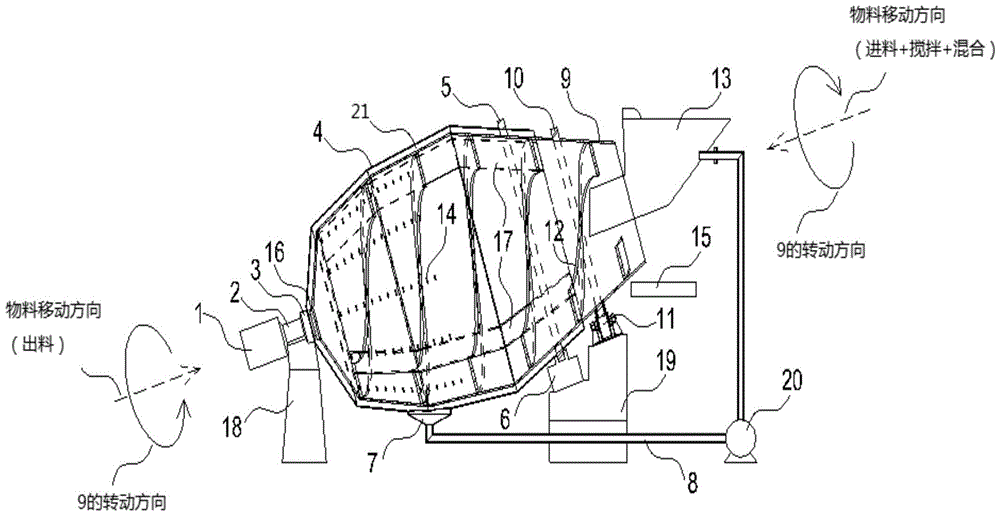

[0037]A silage method and silage material mixing device for preparing biogas by anaerobic fermentation of energy herb plants, specifically adding fresh grass and molasses alcohol wastewater into the inner barrel 9 through the feed hopper 13 in proportion, and the power unit 1, the transmission The device 2 drives the inner barrel 9 to rotate, and the outer barrel 4 is stationary. When the inner barrel 9 rotates, the liquid in the mixture will be separated into the liquid collection chamber 21 through the filtrate hole 14 . The liquid returns to the inner bucket through the liquid collecting bucket 7, the liquid delivery pipeline 8 and the circulating pump 20. When feeding, the agitator 12 rotates in one direction to fully mix the materials, and forms a large radial agitation on the materials through the supporting plate 17. When the materials are completely mixed, the agitator 12 rotates in the opposite direction to discharge the materials from the tank and convey them through ...

Embodiment 2

[0039] A method for silage of energy herbs used for anaerobic fermentation, specifically crushing cut fresh grass to a length of 1-2 cm, adding 1% to 2% molasses alcohol waste water according to the total weight of the fresh grass, and said molasses alcohol The COD concentration of the waste water is 107500-134000 mg / L. The fresh grass and molasses alcohol waste water are completely mixed and put into silage bags or silage pits for silage for 30-45 days. Take out and analyze and measure the physical and chemical properties of raw materials after silage. The pH value is lower than 5.0, the concentration of lactic acid is above 55mg / g, and the concentration of ammonia nitrogen is below 40mg / g. The biogas is prepared by anaerobic fermentation using the existing technology.

Embodiment 3

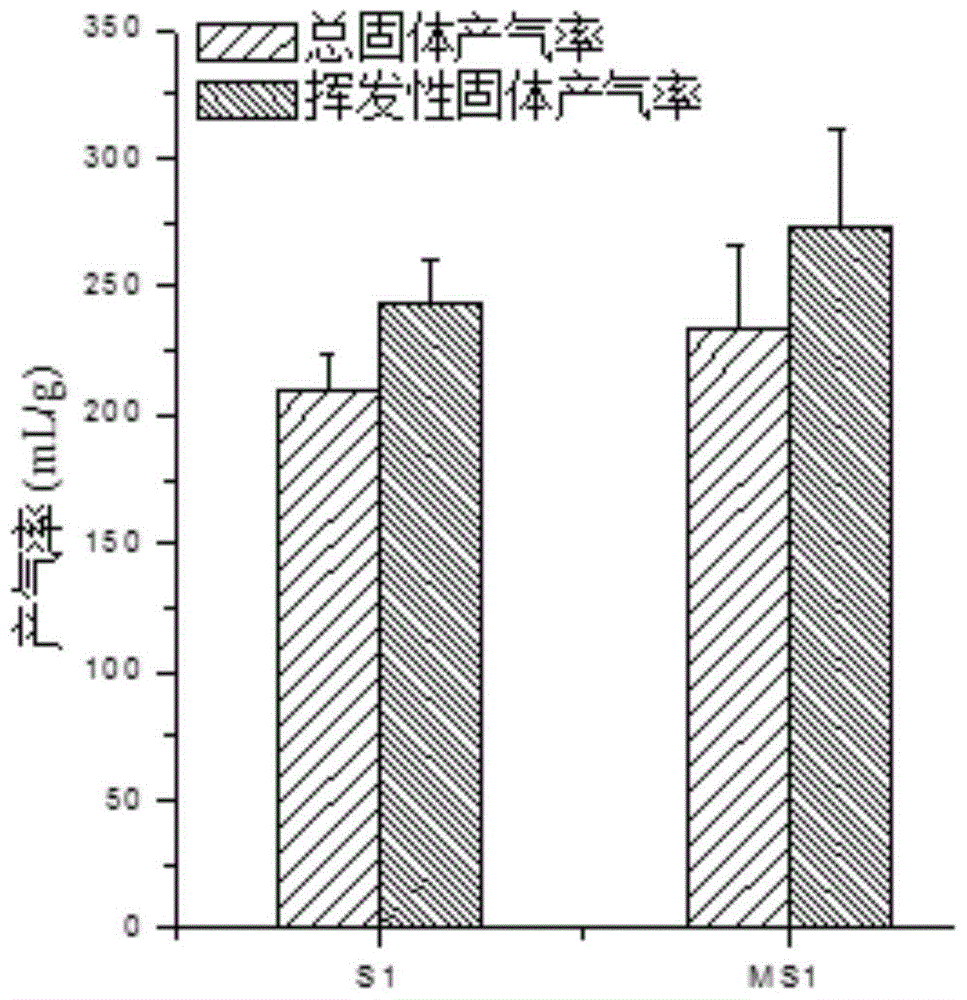

[0041] 1. Use 2% molasses alcohol waste water silage:

[0042] After cutting, the hybrid pennisetum is artificially cut into 1-2cm, and molasses alcohol wastewater is added according to 2% of the wet weight of hybrid pennisetum. The COD concentration of the molasses alcohol wastewater is 107500-134000mg / L, and the two materials are completely After mixing, put it into the silage bag, leave it at room temperature for 45 days after vacuuming, take out the material after ensilage, and carry out anaerobic fermentation. During anaerobic fermentation, the volatile solid substance ratio of the strain to the raw material is 1:1, the volatile solid concentration of the strain is 1.383%, and 0.5g / L ammonium bicarbonate is added, and the fermentation is carried out at a constant temperature (35°C). The fermentation was carried out for 14 days in total.

[0043] 2. No added molasses alcohol wastewater silage:

[0044] The harvested Pennisetum hybrids were manually cut into 1-2 cm, put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com