Organic waste gas adsorptive recovery system and adsorption-desorption method thereof

A technology for organic waste gas and adsorption recovery, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of low desorption efficiency and poor adsorption effect of powdered adsorbents. The effect is obvious and the realization is not good. The effect of continuous desorption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

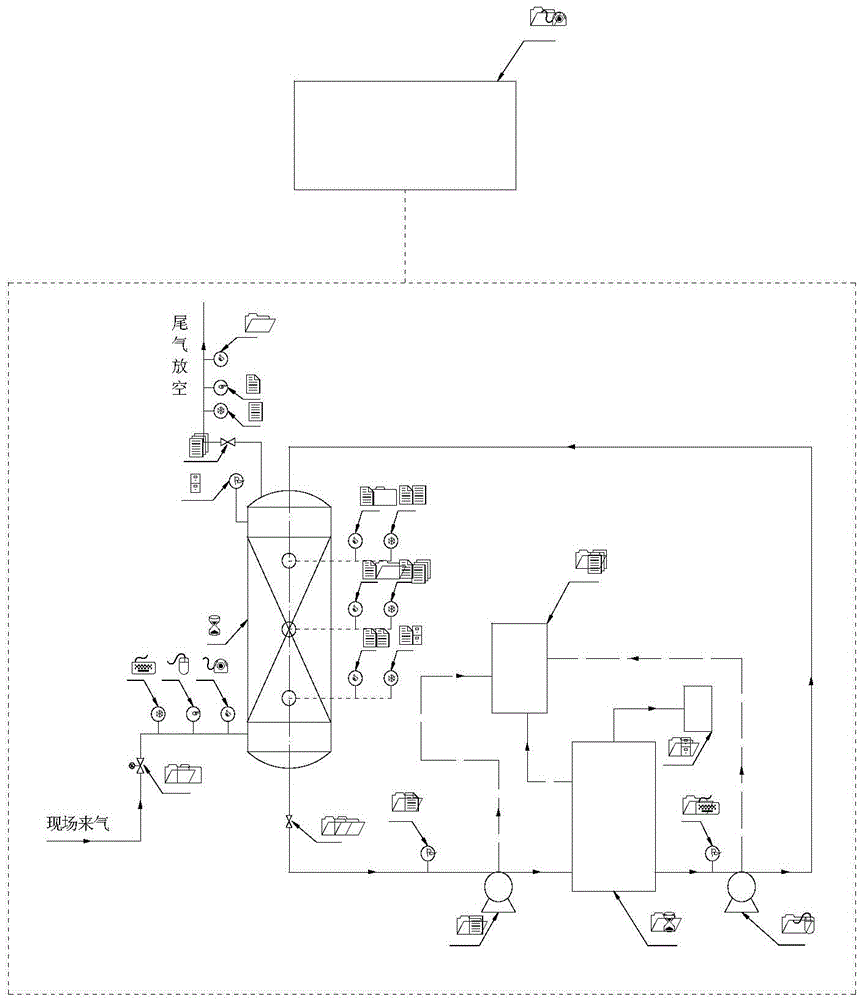

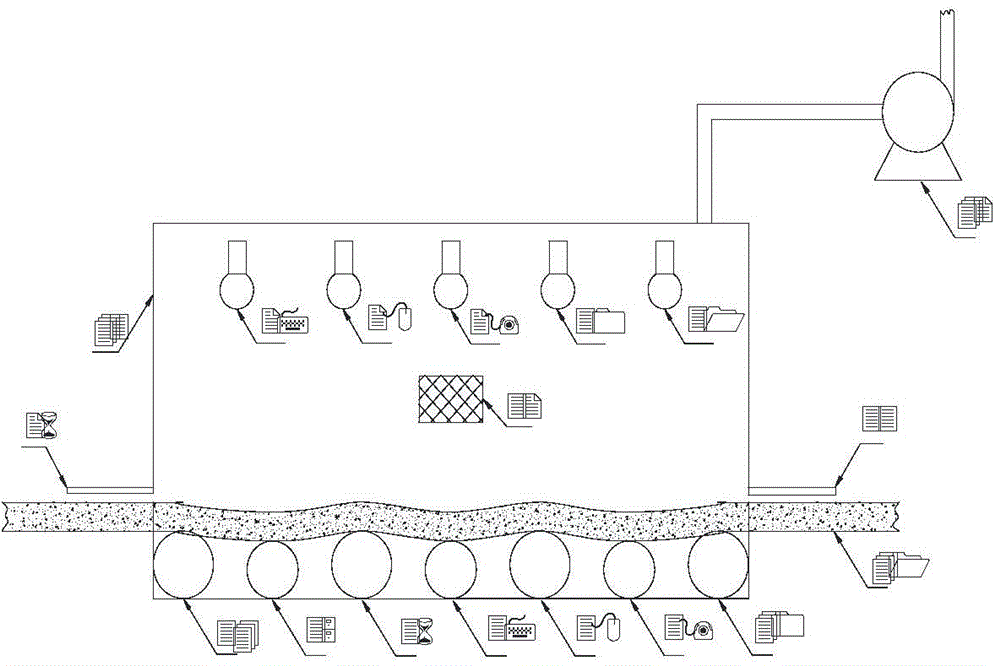

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a process schematic diagram of an embodiment of the organic waste gas adsorption recovery system of the present invention, figure 2 It is a schematic diagram of the internal structure of the "microwave and vacuum" desorption equipment.

[0034] When the on-site air comes in (the loading crane pipe is sealed to fill the railway tanker or automobile tanker, or when the gasoline tanker unloads oil to the underground tanker, the mixture of oil gas and air discharged from the tanker or underground tanker) When the gas) flow rate is 100m3 / h, utilize the technical scheme of the present invention to carry out adsorption separation and recovery to it.

[0035] (1) Organic waste gas adsorption recovery system, such as figure 1 As shown, it includes: adsorption tower 6, "microwave and vacuum" desorption equipment 16, automatic control equipment 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com