Cementing material containing silicon-calcium slag and preparation method thereof

A cementitious material, calcium silicate slag technology, applied in cement production, etc., can solve the problems of less addition of calcium silicate slag, high cost, complex preparation process of calcium silicate slag cement, etc., to achieve reduced production costs, good early strength and The effect of late strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

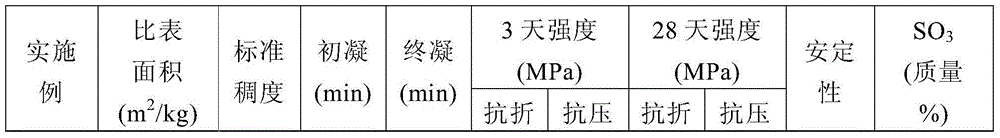

Image

Examples

Embodiment 1

[0030] Calcium silicon slag (dried to moisture content ≤ 2%), fly ash, cement clinker, granulated blast furnace slag, desulfurized gypsum and calcium lignosulfonate are mixed evenly according to the weight ratio, and then ground to a particle size of 400m 2 / kg, made cementitious material, and it comprises following components according to percentage by weight: calcium silicate slag 54%, fly ash 14%, cement clinker 20%, granulated blast furnace slag 6%, desulfurization gypsum 5%, Calcium lignosulfonate 1%.

[0031] According to the GB175-2007 "General Portland Cement" standard, the quality of the cementitious material is tested,

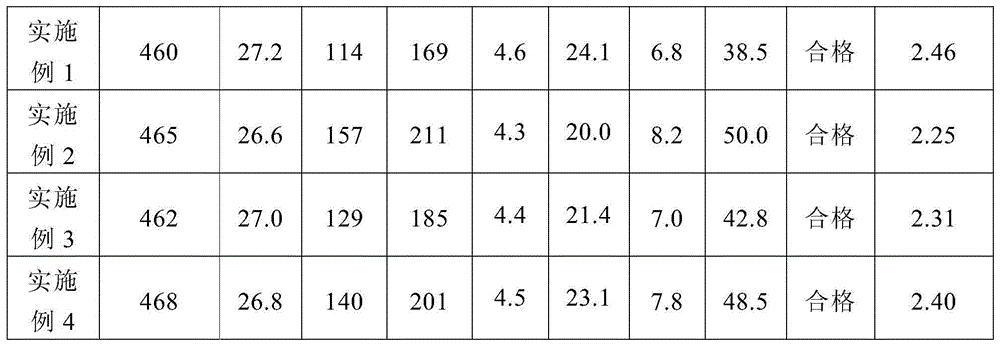

[0032] The test results are shown in Table 1.

Embodiment 2

[0034] Calcium silicate slag (dried to moisture content ≤ 2%), fly ash, cement clinker, granulated blast furnace slag, anhydrous gypsum, sodium chloride and sodium phosphate are mixed evenly according to the weight ratio, and then ground to Particle size is 500m 2 / kg, to obtain cementitious material, which comprises the following components according to weight percentage: 44% of calcium silicate slag, 10% of fly ash, 25% of cement clinker, 15% of granulated blast furnace slag, and 5% of anhydrous gypsum , 0.5% sodium chloride, 0.5% sodium phosphate; the quality test results of the gelled material are shown in Table 1.

Embodiment 3

[0036] Calcium silicate slag (dried to moisture content ≤ 2%), fly ash, cement clinker, granulated blast furnace slag, dihydrate gypsum, and sodium polyphosphate are mixed evenly according to the weight ratio, and then ground to a particle size of 300m 2 / kg, to obtain cementitious material, which comprises the following components according to weight percentage: 65% calcium silicate slag, 5% fly ash, 15% cement clinker, 10% granulated blast furnace slag, 3% dihydrate gypsum , sodium polyphosphate 2%; the quality inspection results of the gelled material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com