An Embedded Controller of Turntable Knife Grinder Based on Digital Bus

A technology of embedded controller and digital bus, applied in the field of embedded controller of rotary knife sharpening machine, can solve the problems of complex implementation, lack of pertinence in functions, unable to meet specific process requirements, and high hardware cost, and achieve low hardware cost, The software function customization and upgrading are convenient, and the control function is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

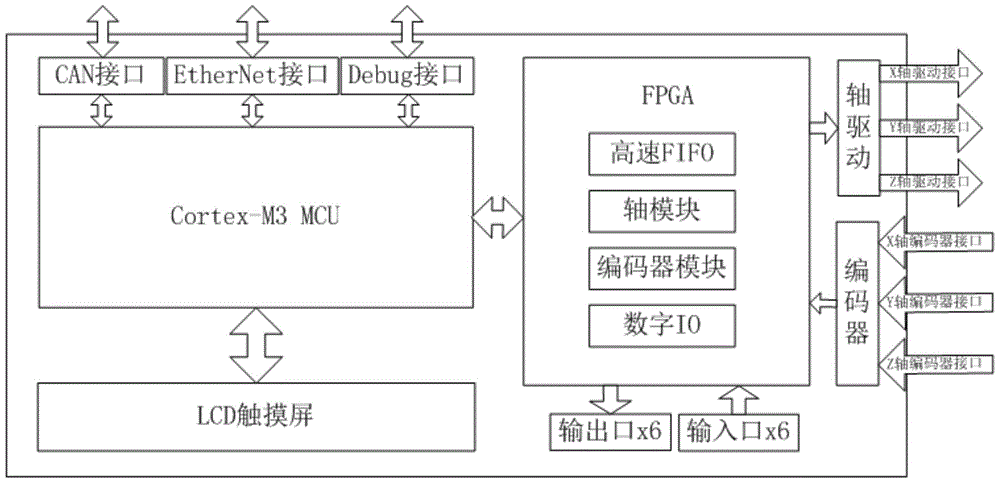

[0025] figure 1 Among them, the CAN (CONTROL AREA NETWORK) bus interface is used for the bus communication between multiple controllers; the Ethernet (Ethernet) bus interface is used for the data communication between the controller and the industrial PC online debugging process; the Debug (debugging) interface , used for programming and debugging the chip; LCD (Liquid Crystal Display), that is, a liquid crystal display, the present invention uses a liquid crystal display with a touch screen function; FIFO (First Input First Output) first-in-first-out queue mechanism, As an access method for the data transfer process.

[0026] Such as figure 1 , an embedded controller for a turntable knife sharpener based on a digital bus, including an ARM processor, an FPGA processor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com