Enhanced grooved Schottky diode rectification device and fabrication method thereof

A technology of Schottky diodes and rectifier devices, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc. It can solve the problems of limited improvement of device reverse voltage blocking ability, leaving holes, affecting device reliability, etc. , to achieve the effect of enhancing the reverse voltage blocking ability and strong gap filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

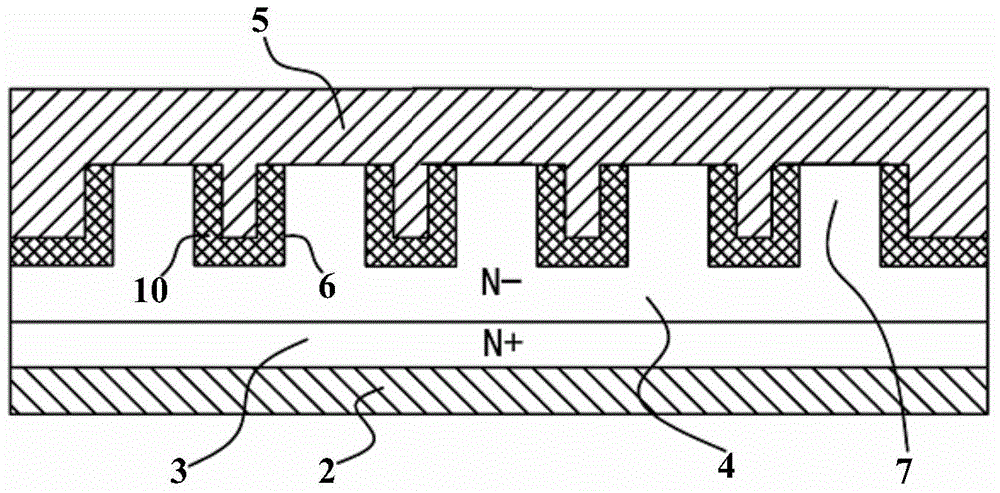

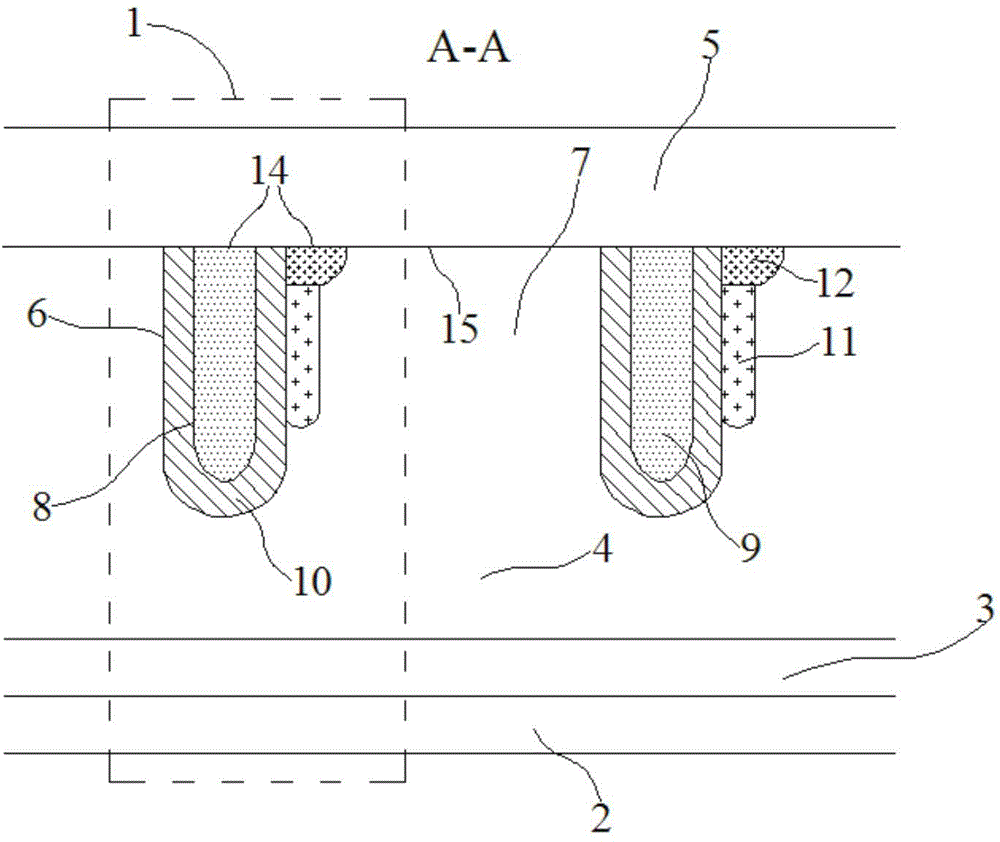

[0038] Embodiment: an enhanced trench type Schottky diode rectifier device, on the top view plane, the active region of the device is composed of several Schottky barrier diode cells 1 connected in parallel, the Schottky barrier diode In the longitudinal section of the unit cell 1, each Schottky barrier diode unit cell 1 includes a lower metal layer 2 located on the back of the silicon wafer, and a substrate layer 3 heavily doped with the first conductivity type located above the lower metal layer 2. An ohmic contact is formed between the substrate layer 3 and the lower metal layer 2, an epitaxial layer 4 lightly doped with the first conductivity type located above the substrate layer 3, and an upper metal layer 5 located above the epitaxial layer 4, from the epitaxial The upper surface of the layer 4 extends to the groove 6 in the middle of the epitaxial layer 4, and the region of the epitaxial layer 4 between adjacent grooves 6 forms a single crystal silicon boss 7 of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com