Method for ohmic contact between copper indium gallium diselenide and molybdenum and solar cell preparation method

An ohmic contact, copper indium gallium selenide technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of destroying the mechanical connection performance of CIGS thin film and Mo thin film, increasing the contact resistance between Mo thin film and CIGS thin film, and increasing the series resistance of CIGS battery. and other problems, to achieve the effect of saving industrial development, reducing additional processing, and avoiding uncontrollability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

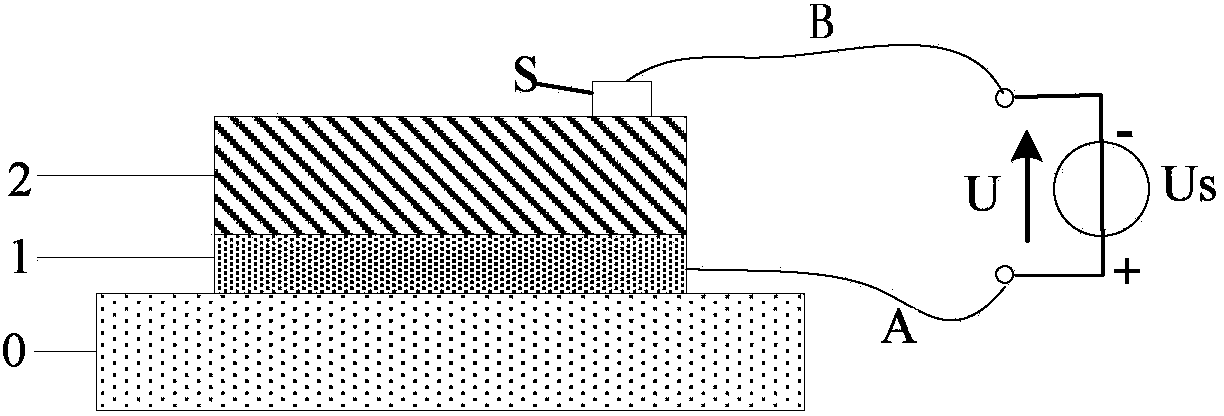

[0031] Such as figure 1 As shown, the method for changing the ohmic contact between copper indium gallium selenide and molybdenum in this embodiment includes the following steps:

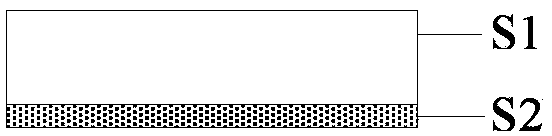

[0032] 1) Prepare a 500nm Mo thin film 1 on a glass substrate 0 by sputtering;

[0033] 2) A 1.2 μm CIGS thin film 2 was prepared on the Mo thin film 1 by the selenization method after sputtering;

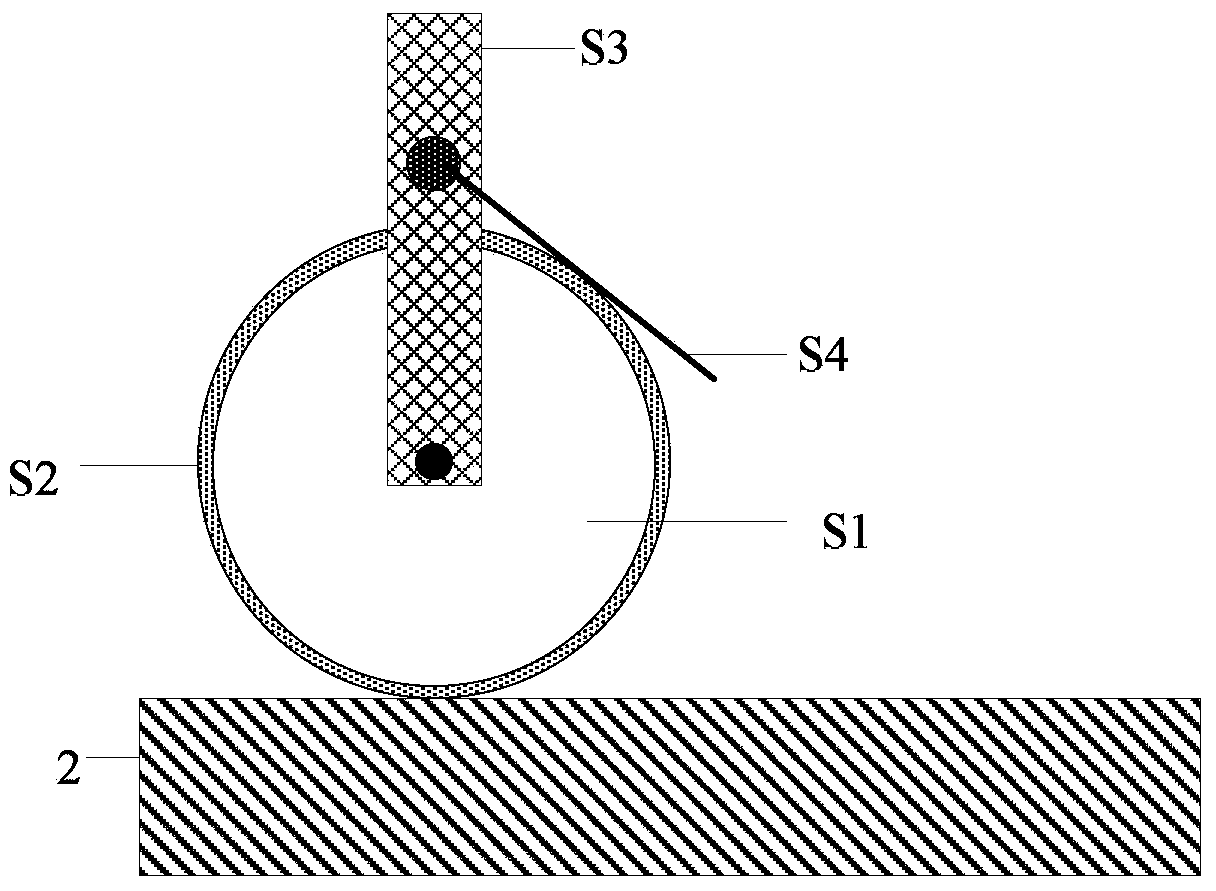

[0034] 3) Provide two electrode lines, one end of the first electrode line A is connected to the positive pole of the power supply, the other end is connected to the Mo film 1, one end of the second electrode line B is connected to the negative pole of the power supply Us, and the other end is connected to the scanning component S, the scanning component S is placed on the CIGS film 2, in this embodiment, the scanning component S uses a scanning slider;

[0035]4) Turn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com