Laminated organic light emitting diode

An electroluminescent device, an organic technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems that technicians cannot obtain technical solutions from this, and achieve the purpose of improving current efficiency and luminous efficiency, improving power efficiency, Effect of High Current Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In this embodiment, an ITO conductive glass substrate with a specific pattern etched is used as the substrate, and the substrate is ultrasonically cleaned in deionized water containing a cleaning solution. The temperature of the cleaning solution is about 60°C, and then infrared baking is used. The lamp bakes the cleaned substrate, and puts it into the evaporation chamber to evaporate the anode layer, a number of the light-emitting unit layers (and the connection between adjacent light-emitting unit layers). Layer) and the cathode layer, the chamber pressure during the evaporation process is lower than 1.0×10-3Pa.

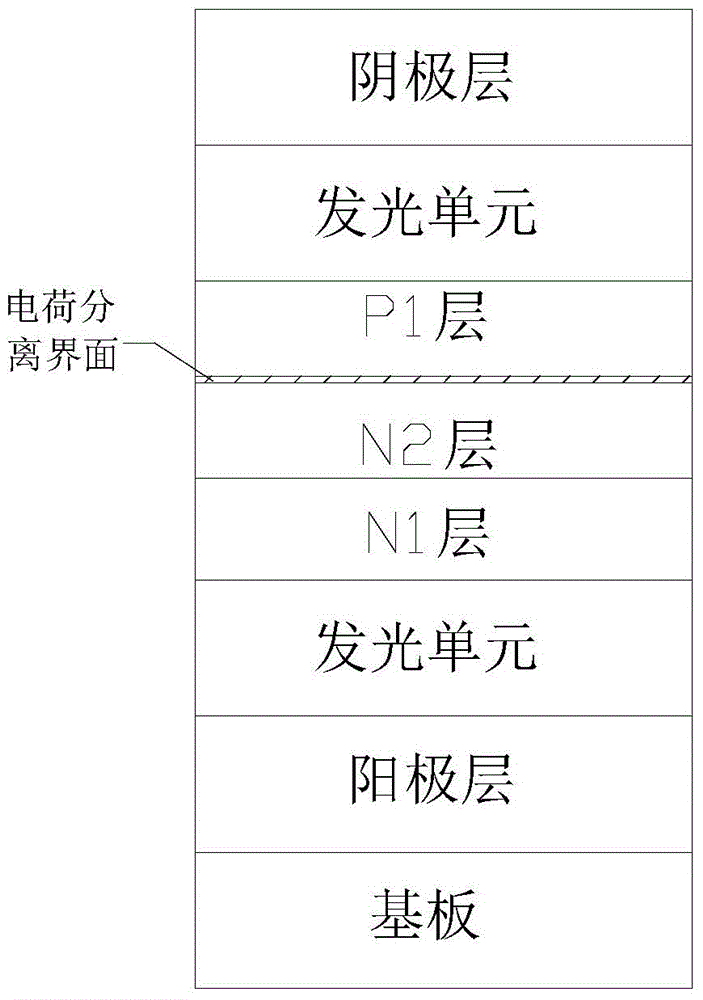

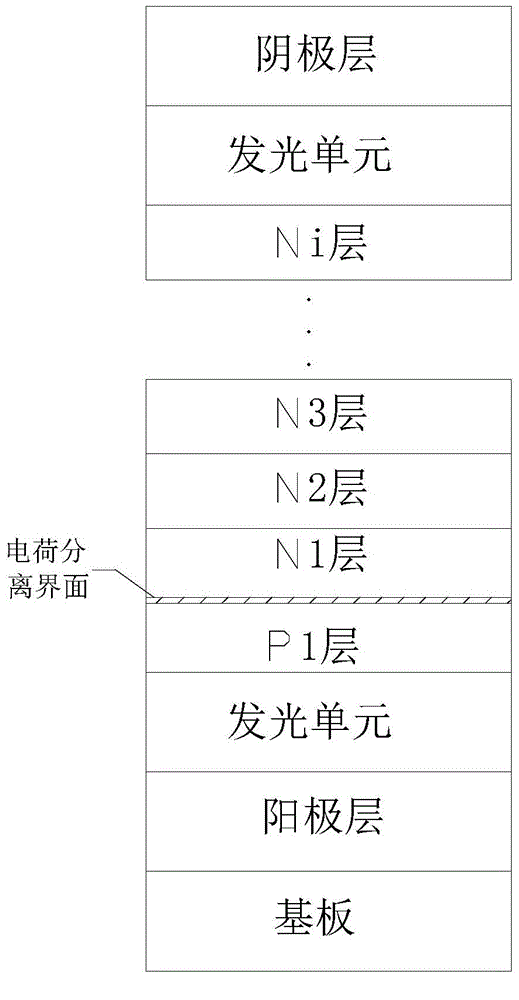

[0083] The device structure is:

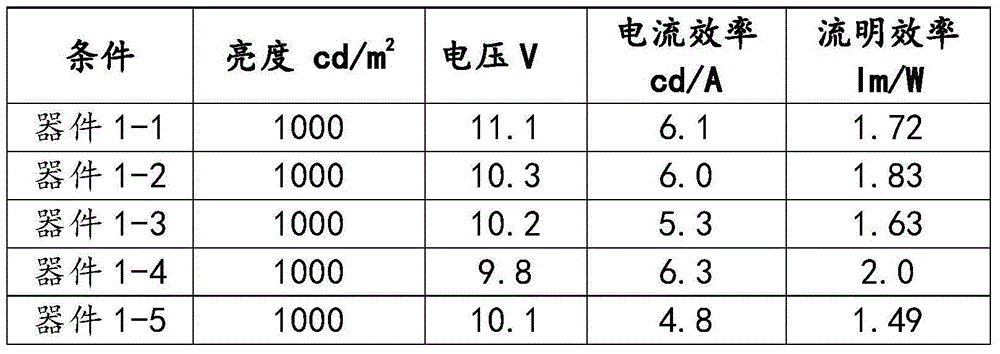

[0084] Device 1-1:

[0085] ITO / NPB(80nm) / EL / N1 / N2 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0086] Device 1-2:

[0087] ITO / NPB(80nm) / EL / N1 / N2 / N3 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0088] Devices 1-3:

[0089] ITO / NPB(80nm) / EL / N1 / N2 / N3 / N4 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0090] Devices 1-4:

[0091] ITO / NPB(80nm) / EL / N1(...

Embodiment 2

[0118] The processing process of this embodiment is similar to the first embodiment.

[0119] The device structure is:

[0120] Device 2-1:

[0121] ITO / NPB(80nm) / EL / N1 / N2 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0122] Device 2-2:

[0123] ITO / NPB(80nm) / EL / N1 / N2 / N3 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0124] Device 2-3:

[0125] ITO / NPB(80nm) / EL / N1 / N2 / N3 / N4 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0126] The above-mentioned device 2-1 is a device structure of the prior art, which is a comparative example of the second embodiment; and the device 2-2 and the device 2-3 are the device structures proposed by the present invention. The specific structures and materials of the above device 2-1, device 2-2, and device 2-3 are described in detail as follows:

[0127] Device 2-1 is an existing device structure, and its connection layer includes two electron transport layers (N1 and N2) and a hole transport layer (P1), namely N1 / N2 / P1 layer structure, N1 / N2 / P1 layer Connect the two light-em...

Embodiment 3

[0148] The processing process of this embodiment is similar to the first embodiment.

[0149] The device structure is:

[0150] Device 2-2:

[0151] ITO / (NPB80nm) / EL / N1 / N2 / N3 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0152] Device 2-4:

[0153] ITO / (NPB80nm) / EL / N1 / N2 / N3 / P1 / EL / Alq 3 (30nm) / LiF(0.5nm) / Al(150nm)

[0154] Among them, the device 2-2 is the same as the second embodiment.

[0155] The connection layer of device 2-2 has three electron transport layers (N1, N2 and N3) and one hole transport layer (P1), namely N1 / N2 / N3 / P1 layer structure, N1 / N2 / N3 / P1 layer Connect the two light-emitting unit layers in series, and the two light-emitting unit layers EL are single-layer luminescent Alq 3 . among them:

[0156] Electron transport layer N1, using Alq 3 :Li, thickness is 30nm, of which Alq 3 The LUMO energy level is 3.1eV;

[0157] The electron transport layer N2 uses PTCBI with a thickness of 2nm and a LUMO energy level of 4.1eV;

[0158] The electron transport layer N3 uses a HAT with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com