Structure having a core bar

A technology for building materials and sandwiches, applied in construction, building components, building structures, etc., can solve the problems of wasting metal materials, increasing economic burden, prolonging working hours, etc., achieving light price burden, saving mechanical strength, and improving construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

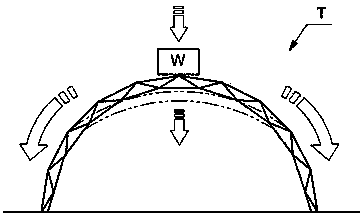

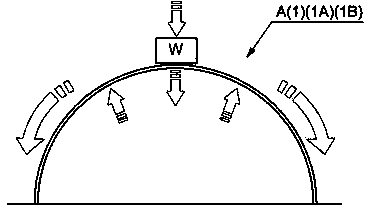

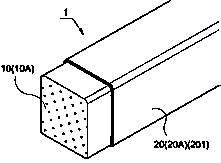

[0052] The following is a case description of the sandwich (core bar) building material of the present invention, which is explained in detail according to the accompanying drawings.

[0053] The sandwich (core bar) building material 1 of the present invention includes more than one elastic bar-shaped core (core bar) 1 as shown in FIGS.

[0054] The above-mentioned sandwich 10 is composed of any one or more of bamboo strips 1 or bamboo integrated strips 10A, wood, synthetic plastics, glass fiber composite materials, and carbon fiber composite materials;

[0055]The housing 20 or skin 20A is formed of any one or more of metal materials including aluminum, synthetic plastics, glass fiber composite materials, and carbon fiber composite materials.

[0056] The above-mentioned sandwich 10 is composed of bamboo integrated strips 10A with good flexibility, tensile strength and recovery elasticity; and the bamboo integrated strips 10A can be formed by multiple bamboo strips 11 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com