A device and method for measuring total volumetric density of rock samples

A measurement method and a technology of a measurement device, which are applied in the field of oil and gas geological exploration and development, can solve the problems of difficult control of precision, cumbersome operation process, and many operation links, so as to avoid human error, shorten the analysis cycle, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

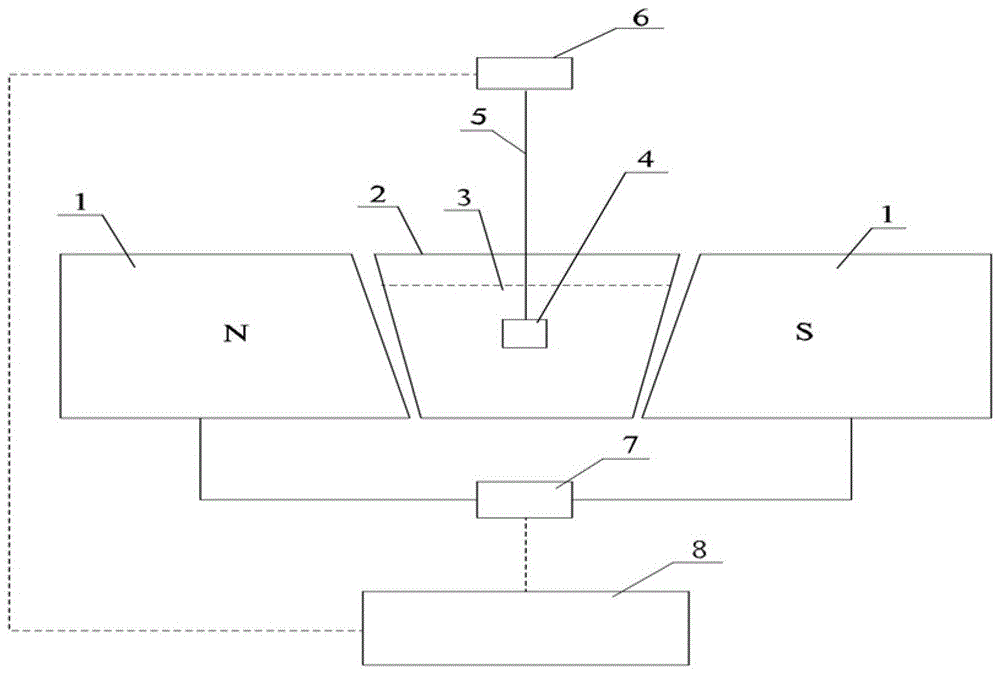

[0048] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0049] The invention provides a method for measuring the total volumetric density of rock samples. Mainly adopt the following ideas and technical means:

[0050] (1) Measuring principle

[0051] According to Archimedes' principle, an object immersed in a liquid is subject to an upward buoyant force equal to the weight of the liquid displaced by the object.

[0052] Assuming that the rock sample is submerged in the first liquid, the buoyancy it receives is:

[0053] f 1 =D 1 *V=G 01 -G 1 (1)

[0054] Among them, F 1 : buoyancy received;

[0055] D. 1 : the density of the first liquid;

[0056] V: the total volume of the rock sample;

[0057] G 01 : The weight of the rock sample in the air after soaking in the first liquid;

[0058] G 1 : the weight of the rock sample in the first liquid;

[0059] Assuming that the rock sample is submerged in the second li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com