Method for predicting baked piece smoke hydrogen cyanide based on robust regression modeling

A robust regression and hydrogen cyanide technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve laborious, time-consuming, high-cost problems, reduce detection costs, ensure robustness, and improve detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

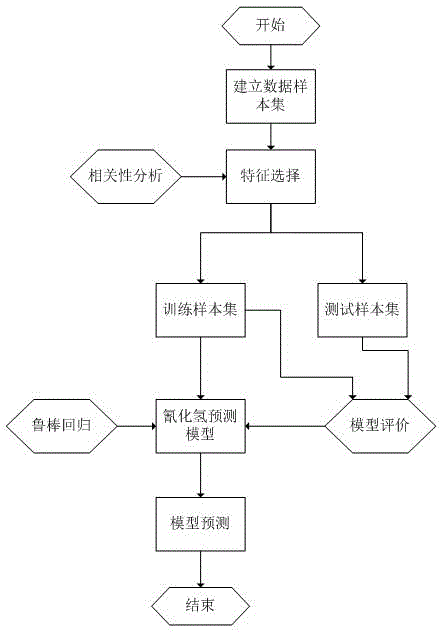

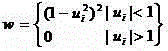

Method used

Image

Examples

Embodiment 1

[0050] (1) List the physical and chemical data of the known baked slices and the flue gas HCN data correspondingly, and establish a data sample set, in which the physical and chemical data include total sugar, reducing sugar, nicotine, total volatile alkali, total nitrogen, nicotine nitrogen, protein , Shimuke value, nitrogen-alkaline ratio, chlorine, potassium, sugar-alkaline ratio and ammoniacal alkali, as shown in the following table:

[0051]

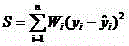

[0052] (2) Calculate the column vector x of each physical and chemical data in the data sample set obtained in step (1) 1 ~x n and the column vector y of flue gas HCN data, the linear correlation coefficient r between each physical and chemical data and flue gas HCN is calculated by the following formula:

[0053] (1)

[0054] In the formula: x is a column vector of some physical and chemical data, y is the column vector of flue gas HCN data; the linear correlation coefficient r between the physical an...

Embodiment 2

[0098] Same as steps (1) to (3) of Example 1, only replace other roasted slices to be tested, step (4) is as follows:

[0099] According to the characteristic index items selected in step (2), the corresponding physical and chemical data of the roasted slices to be tested are nicotine=2.26, total volatile alkalis=0.28, total nitrogen=1.9, nicotine nitrogen=0.39, protein=9.43, wood Gram value = 2.75 is applied as an input variable to the prediction model of step (3), and the model prediction value Y=106.63990-304.78669*nicotine-62.56795*total volatile alkalis+2899.43742 can be obtained *Total Nitrogen-1101.50935*Nicotine Nitrogen-459.45547*Protein-12.02897*Shimug value=113.9007. In order to verify the reliability of the prediction results of the model, the traditional detection method was used to measure the HCN value of the flue gas of the baked sheet: 112.25.

Embodiment 3

[0101] Same as steps (1) to (3) of Example 1, only replace other roasted slices to be tested, step (4) is as follows:

[0102] According to the characteristic index items selected in step (2), the corresponding physical and chemical data of the roasted slices to be tested are nicotine=2.4, total volatile alkalis=0.29, total nitrogen=1.8, nicotine nitrogen=0.42, protein=8.66, wood The gram value=3.24 is applied to the prediction model in step (3) as an input variable, and the model prediction value Y=106.63990-304.78669*nicotine-62.56795*total volatile alkalis+2899.43742 can be obtained *Total Nitrogen-1101.50935*Nicotine Nitrogen-459.45547*Protein-12.02897*Shimug value=95.5023. In order to verify the reliability of the prediction results of the model, the HCN value of the flue gas of the baked sheet was determined to be 96.07 by using the traditional detection method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com