Preparation method of an organic/inorganic hybrid material and its application in the specific adsorption-catalyzed degradation of triphenylmethane dyes

A hybrid material, specific technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of no obvious adsorption of dyes, and achieve excellent The effect of catalytic degradation performance, short time, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation and application steps of the hybrid material of the present invention are as follows:

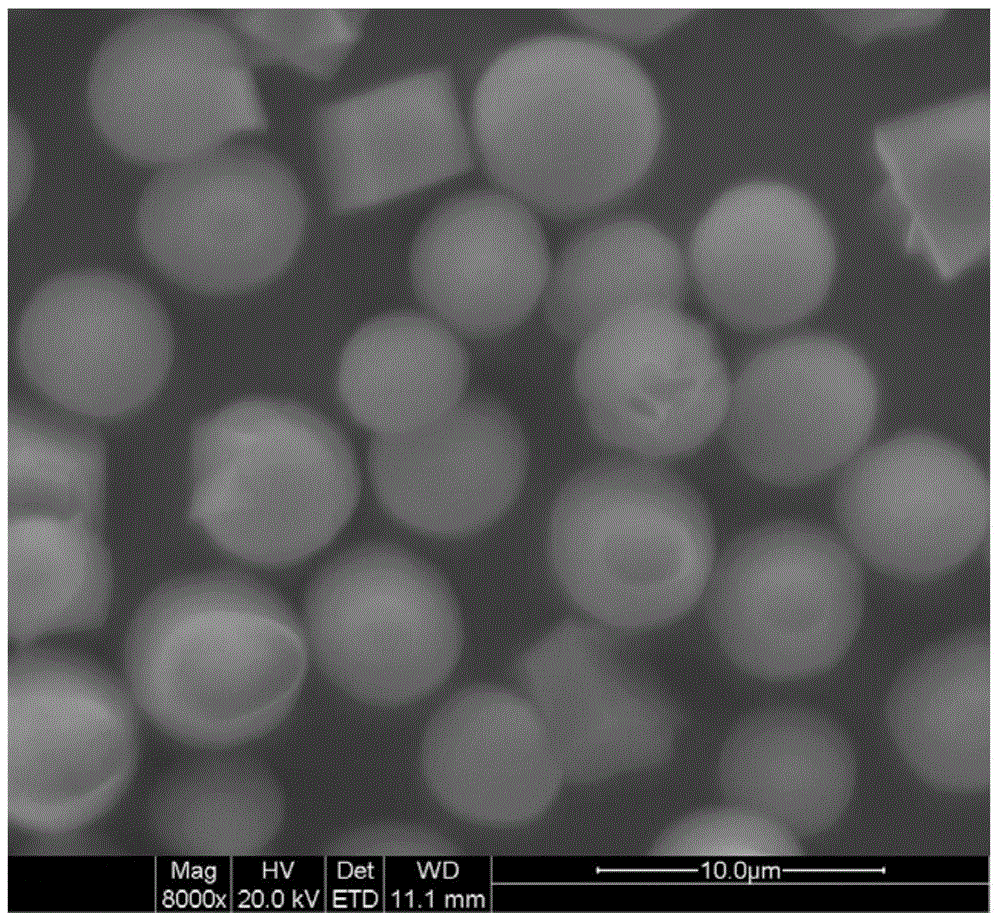

[0027] (1) CaCO 3 / Preparation of lentinan (LTN) hybrid material

[0028] A gram of analytically pure lentinan solid is dissolved in BmL of 0.1-0.3mol / L calcium chloride solution, fully stirred at room temperature and added CmL of 0.1-0.3mol / L sodium carbonate solution, wherein the suspension is configured CO 3 2- : Ca 2+ The initial molar ratio is 1:(0.5~2), and the amount of lentinan added is less than 5% of the total volume of the mixed solution, that is, A:(B+C)=(0~5):100, and A is not equal to 0, After 8-12 minutes of reaction, a white suspension was obtained. Suction filter the completely reacted white suspension, wash the separated solid phase first with water and then with alcohol, dry it in vacuum at 30-50°C for 1-2 hours and ultrasonically treat it to finally obtain the target product, which is CaCO 3 / LTN hybrid material.

[0029] (2)CaCO 3 / LTN hy...

Embodiment 1

[0039]Dissolve the analytically pure lentinan solid in 0.3mol / L calcium chloride solution, fully stir at room temperature and add 0.3mol / L sodium carbonate solution, and configure the CO of the mixed solution 3 2- : Ca 2+ The initial molar ratio was 1:1, the amount of lentinan added was 2.5% of the total amount of the mixed solution, and a white suspension was obtained after 10 min of reaction. Suction filter the completely reacted white suspension, wash the separated solid phase with water first and then with alcohol, dry it in vacuum at 40° C. for 1.5 h, and process it ultrasonically to finally obtain the target product.

Embodiment 2

[0041] Dissolve the analytically pure lentinan solid in 0.2mol / L calcium chloride solution, fully stir at room temperature and add 0.2mol / L sodium carbonate solution, and configure the CO of the mixed solution 3 2- : Ca 2+ The initial molar ratio was 1:0.5, the amount of lentinan added was 3% of the total amount of the mixed solution, and a white suspension was obtained after 8 minutes of reaction. The completely reacted white suspension was suction-filtered, the separated solid phase was washed with water and then with alcohol, dried in vacuum at 30°C for 2 h and ultrasonically treated to finally obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com