A kind of beneficiation process for processing diamond and magnetic mixed ore

A technology of ore and process, which is applied in the field of iron ore separation, can solve the problems of large difference in embedded particle size and ineffective recovery, etc., and achieve the effect of reducing grinding energy consumption, reducing beneficiation cost, and saving grinding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

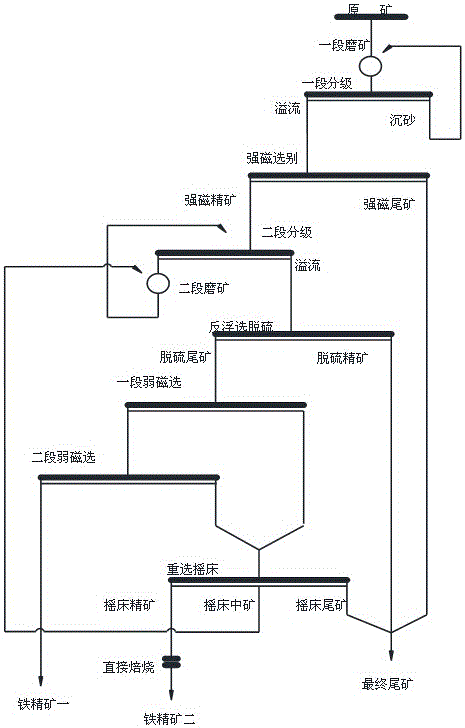

[0022] A beneficiation process for processing diamond-magnetic mixed ore, comprising the following process steps:

[0023] a) Feed the crushed diamond and magnetic mixed ore raw ore into the first-stage grinding closed-circuit system composed of the first-stage mill and the first-stage grading cyclone group for circular grinding and classification, specifically, after being ground by the first-stage mill The ore enters the first-stage classifying cyclone group to form -200 mesh overflow material and grit-set material, which account for 60-70% of the material, and the grit-set returns to the first-stage mill to continue grinding and grading, so that the cycle continues and the overflow material that meets the requirements is produced. The overflow material discharged from a classifying cyclone group is subjected to strong magnetic separation. The magnetic field strength of the strong magnetic separation is 4000 Oe, and the strong magnetic tailings with an iron grade of 11.23% ar...

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 is:

[0029] In step a), the magnetic field strength of the strong magnetic separation is 3500 Oe, the iron grade of the thrown strong magnetic tailings is 11.64%, and the iron grade of the strong magnetic concentrate obtained is 41.87%;

[0030] In step c), the magnetic field strength of the first-stage weak magnetic separation is 2500 Oe, and the magnetic field strength of the second-stage weak magnetic separation is 800 Oe, and the iron grade of the final iron concentrate 1 obtained is 63.22%;

[0031] In step d), the iron grade of the shaker tailings thrown out after shaker gravity separation is 18.55%, and the iron grade of the obtained shaker concentrate is 47.66%; the roasting conditions for direct roasting are: roasting temperature 600~650°C, The roasting time is 45 minutes; the iron grade of the obtained final iron concentrate II is 58.21%.

Embodiment 3

[0033] The difference between embodiment 3 and embodiment 1 is:

[0034] In step a), the magnetic field strength of the strong magnetic separation is 5000 Oe, the iron grade of the thrown strong magnetic tailings is 9.89%, and the iron grade of the strong magnetic concentrate obtained is 41.90%;

[0035] In step c), the magnetic field strength of the first-stage weak magnetic separation is 2000 Oe, and the magnetic field strength of the second-stage weak magnetic separation is 900 Oe, and the iron grade of the final iron concentrate 1 obtained is 62.71%;

[0036] In step d), the iron grade of the shaker tailings thrown out after shaker gravity separation is 19.03%, and the iron grade of the obtained shaker concentrate is 48.06%; the roasting conditions for direct roasting are: roasting temperature 650~700°C, The roasting time is 30 minutes; the iron grade of the obtained final iron concentrate II is 58.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com