Ultrahigh-toughness cement-based composite material used in ejection, and ejection process thereof

A technology of ultra-high toughness, composite materials, applied in the fields of manufacturing tools, climate sustainability, sustainable waste disposal, etc. Good rheological properties, easy to use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

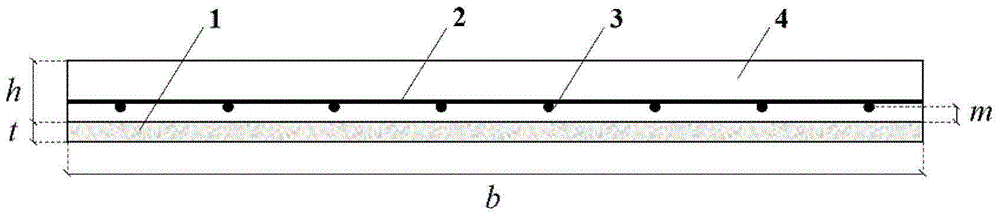

[0042] In this example, a reinforced concrete slab is sprayed with ultra-high toughness cement-based composite material as an existing reinforced concrete structure to achieve enhanced crack control (such as figure 2 shown), where 1 is the ultra-high toughness cement-based composite material layer to be sprayed, 2 is the distributed reinforcement of the existing reinforced concrete structure, 3 is the stressed reinforcement of the existing reinforced concrete structure, and 4 is the existing reinforced concrete structure concrete. The length a=2340mm of the existing reinforced concrete structure, the width of the existing reinforced concrete structure b =1120mm, the height of the existing reinforced concrete structure h =80mm, the distance from the core of the steel bar in the tension zone of the existing reinforced concrete structure to the edge of the tension zone of the existing reinforced concrete structure m =20mm, the concrete compressive strength of the existing rein...

Embodiment 2

[0058] On the basis of Example 1, the enhancement target is to adjust the percentage of the bearing capacity that needs to be improved on the basis of the existing bearing capacity of the structure to α =25%, other conditions are the same.

[0059] The spray thickness of the ultra-high toughness cement-based composite material ( t ) is the minimum thickness required to meet the stated structural reinforcement needs t 1 =10mm, the minimum thickness required to meet the crack control requirements t 2 =9mm. Considering that the structure needs to meet the requirements of reinforcement and crack control at the same time, t need to be satisfied at the same time t 1 and t 2 , so take t = t 1 =10mm.

[0060] Other implementation steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com