Synthesis method of three-terminal epoxy-modified silicone oil

A synthetic method and technology of modifying silicon, which is applied in the chemical field to achieve the effect of wide application range, high temperature resistance, and suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Step 3, the preparation of three-terminal epoxy-modified silicone oil, the capping agent prepared in step 2 and octamethylcyclotetrasiloxane (D4), 3-glycidyl propyl (dimethoxy) methyl silane Add it to a three-necked flask, and add 0.05% to 0.1% of tetramethylammonium hydroxide as a catalyst, and react for 4 hours at a temperature of 70°C to 75°C; add glacial acetic acid to the three-necked flask to adjust the pH of the product to 6.8-7.2 , vacuum rotary evaporation to remove low boilers, and collect the three-terminal epoxy-modified silicone oil product.

[0033] The three-necked flask used in the step two and step three is equipped with a thermometer, a reflux condenser and a dropping funnel.

[0034] The catalyst used in the step 3 is tetramethylammonium hydroxide catalyst or potassium hydroxide catalyst.

[0035] The catalyst used in the third step is a basic catalyst.

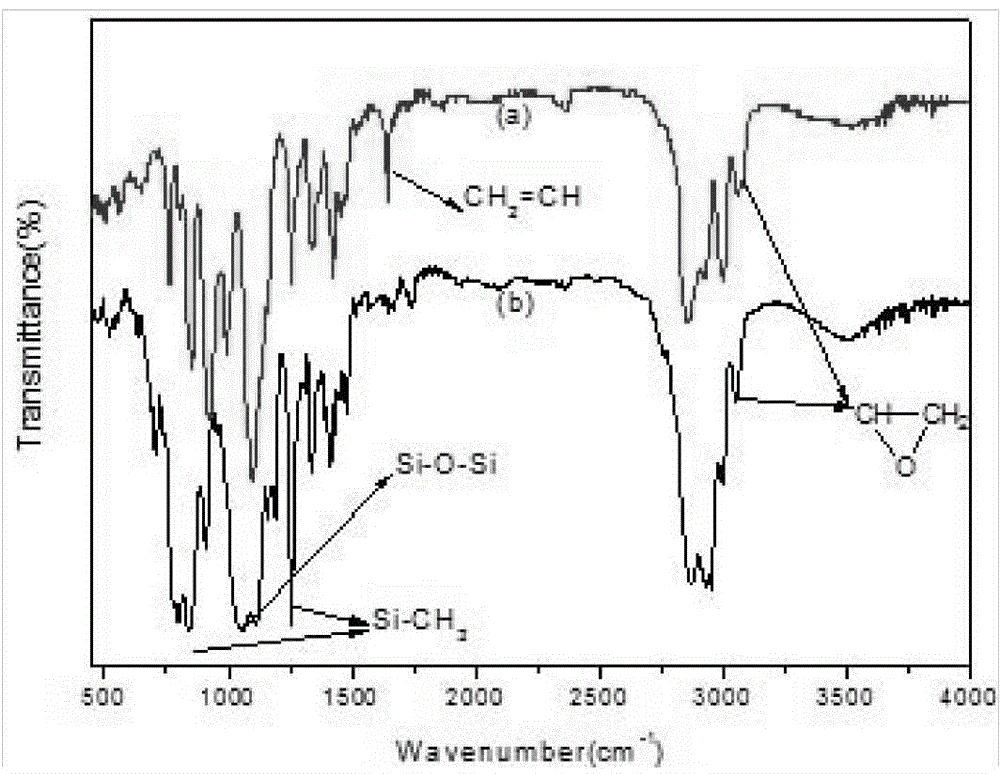

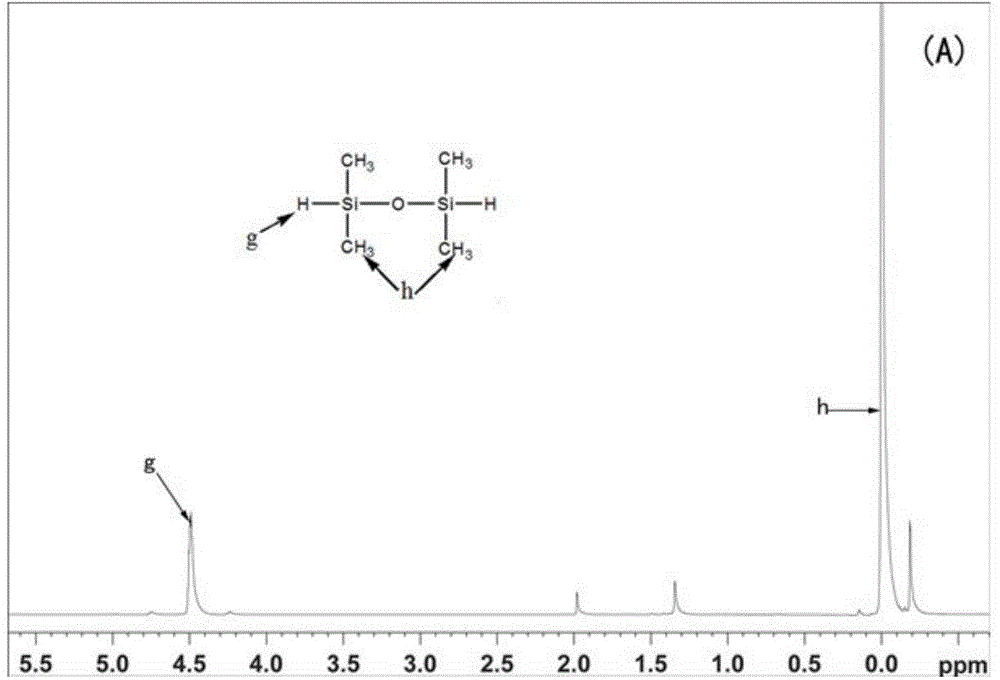

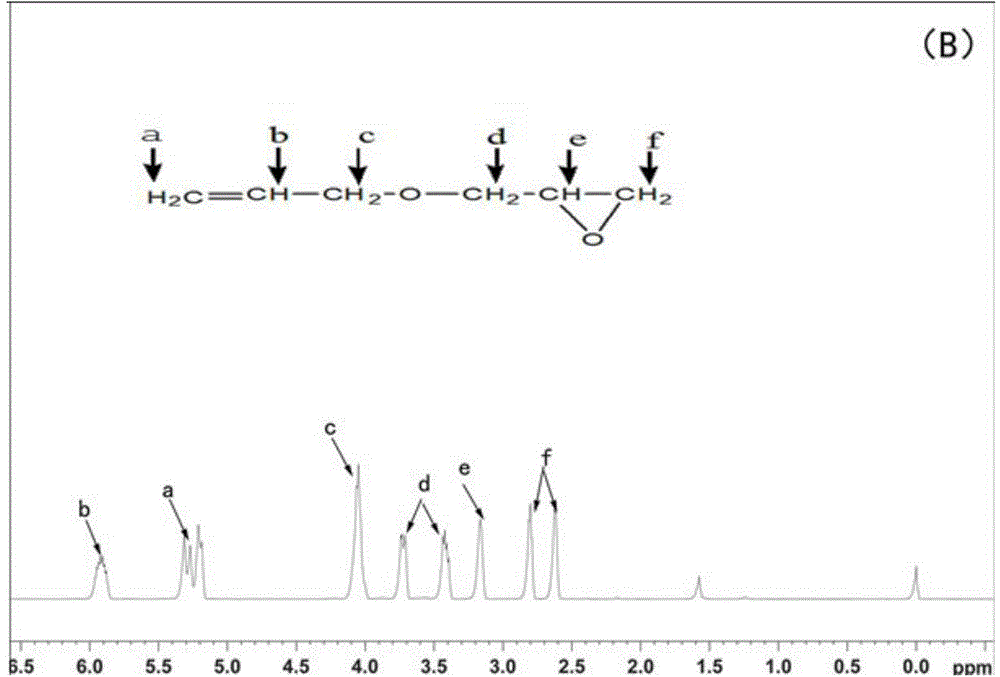

[0036] Such as figure 1 The infrared spectrum of AGE and capping agent shown, in the figure (a...

Embodiment 1

[0043] Embodiment 1, get 5mLAGE and 70ppm catalyst, place in the there-necked flask that is equipped with thermometer, reflux condenser and dropping funnel, under N2 condition, activate 1.5h at 55 ℃, drop 2mLHMM with constant pressure dropping funnel, After the dropwise addition, the reaction was carried out at 58° C. for 4 h. After the reaction, the unreacted monomer was removed by vacuum rotary evaporation to obtain a light yellow liquid. D4: The molar ratio of coupling agent: end-capping agent is 1:1:1, and the amount of catalyst is 0.05% of the total amount of monomers. A three-terminal epoxy-modified silicone oil with a molecular weight of 1013 was obtained.

Embodiment 2

[0044] Example 2, take 5mLAGE and 70ppm catalyst, place in a three-necked flask equipped with a thermometer, a reflux condenser and a dropping funnel, activate it at 55°C for 1.5h under N2 conditions, add 2mLHMM dropwise with a constant pressure dropping funnel, After the dropwise addition, the reaction was carried out at 58° C. for 4 h. After the reaction, the unreacted monomer was removed by vacuum rotary evaporation to obtain a light yellow liquid. D4: The molar ratio of coupling agent: end-capping agent is 2:3:1, and the amount of catalyst is 0.05% of the total amount of monomers. A three-terminal epoxy-modified silicone oil with a molecular weight of 1751 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com