Bottom electrode of DC arc furnace

A DC electric arc furnace and bottom electrode technology, applied in the field of electric arc furnaces, can solve the problems of shortening the service life of the DC electric arc furnace, falling off or thinning of refractory materials, damage of the bottom electrode, etc. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

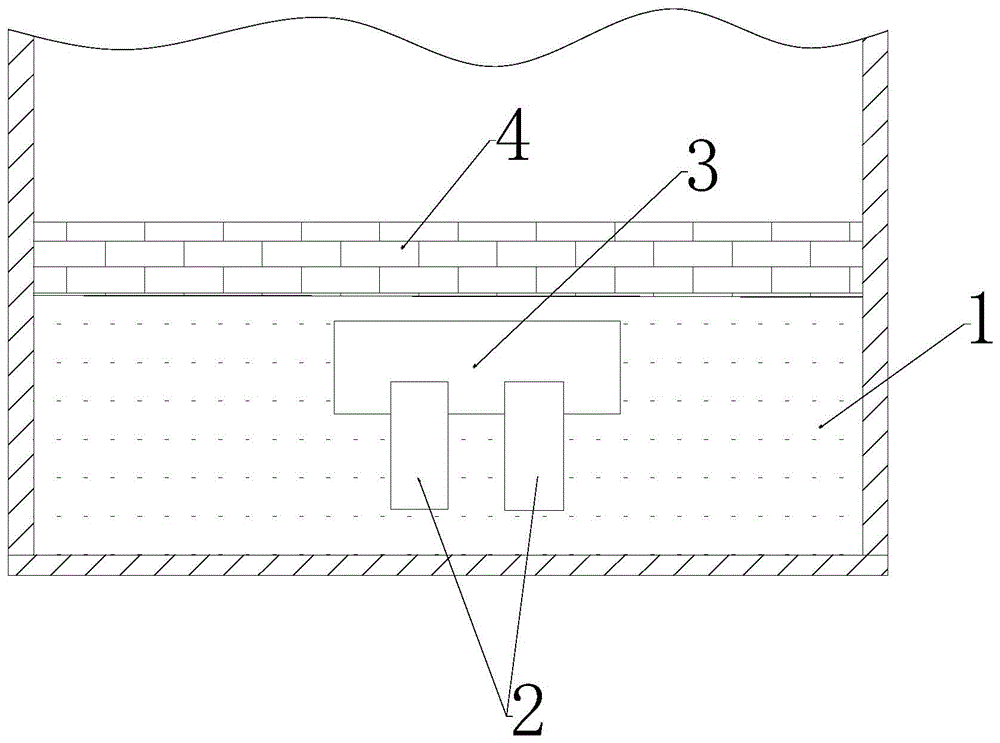

[0025] Embodiment 1: the bottom electrode of DC electric arc furnace comprises a conductive metal rod 2 with a diameter of 50mm and a length of 260mm, and the length, width and thickness of the graphite protective sleeve 3 processed accordingly are 80mm, 80mm, and 150mm respectively, and the conductive metal rod on it is 2 The depth of the blind hole is 70mm, the graphite protective sleeve 3 has a carbon mass fraction of 80%, the furnace bottom refractory material 1 is composed of magnesia and carbon powder, the ratio is 2.5:1, the height after ramming is 350mm, and the magnesium The carbon brick layer 4 has a thickness of 50 mm, and forms the bottom electrode of the DC electric arc furnace after 3 days of curing in the oven. Compared with the bottom electrode of the existing DC electric arc furnace, the service life is increased by about 20%, and the conductivity of the bottom electrode is improved by about 12%.

Embodiment 2

[0026] Embodiment 2: the bottom electrode of DC electric arc furnace comprises a conductive metal rod 2 with a diameter of 50 mm and a length of 260 mm. The length, width and thickness of the graphite protective sleeve 3 processed accordingly are respectively 80 mm, 80 mm and 150 mm. The conductive metal rod on it 2 The depth of the blind hole is 70mm, the graphite protective sleeve 3 has a carbon mass fraction of 90%, the furnace bottom refractory material 1 is composed of magnesia and carbon powder, the ratio is 2.5:1, and the height after ramming is 350mm. The carbon brick layer 4 has a thickness of 50 mm, and forms the bottom electrode of the DC electric arc furnace after 3 days of curing in the oven. Compared with Example 1, the conductivity of the bottom electrode is improved by about 5%, and the service life is the same.

Embodiment 3

[0027] Embodiment 3: the bottom electrode of DC electric arc furnace comprises a conductive metal rod 2 with a diameter of 50mm and a length of 260mm, and the length, width and thickness of the graphite protective sleeve 3 processed accordingly are 80mm, 80mm, and 150mm respectively, and the conductive metal rod on it is 2 The depth of the blind hole is 70mm, the graphite protective sleeve 3 has a carbon mass fraction of 90%, the furnace bottom refractory material 1 is composed of magnesia and carbon powder, the ratio is 3:1, and the height after ramming is 350mm. The carbon brick layer 4 has a thickness of 50 mm, and forms the bottom electrode of the DC electric arc furnace after 3 days of curing in the oven. Compared with Example 1, the service life of the bottom electrode is increased by about 5%, and the conductivity is decreased by 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com