A kind of method for preparing glycolide by catalytic depolymerization at low temperature and high efficiency

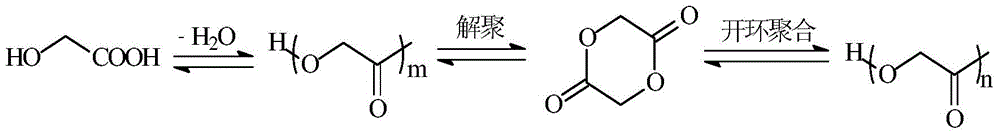

A technology of catalytic depolymerization and glycolide, which is applied in high efficiency, can solve the problems of decreased production of glycolide, increase of by-products, high reaction temperature, etc., and achieve the effect of reducing the temperature of depolymerization and avoiding thermal deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 200g glycolic acid oligomer (weight average molecular weight is 12000) in 500ml four-necked flask, and 0.75g catalyst Sb 2 o 3, heated to 240° C., and decompressed to 1 kPa in a nitrogen atmosphere. During the reaction process, a light yellow liquid evaporates until the reaction ends when no light yellow liquid evaporates in the reaction system, and the light yellow solid obtained by cooling is the crude glycolide product. Glycolide yield 84% (yield is calculated by the formula of "m (obtained light yellow solid crude glycolide product) ÷ m (glycolic acid oligomer raw material) * 100% ", the following examples are the same) , the purity is 87.56%, and the coking rate of the reaction system is 13% (the empty reaction bottle is weighed before the reaction, and the coke is weighed together after the reaction, the difference between the two weights is the coking amount, and then the coking amount is divided by glycolic acid The oligomer raw material quality × 100% jus...

Embodiment 2

[0038] Add 200g glycolic acid oligomer (weight average molecular weight: 10000) and 0.75g catalyst ZnO into a 500ml four-neck flask, heat to 240°C, and depressurize to 1kPa in a nitrogen atmosphere. During the reaction process, a light yellow liquid evaporates until the reaction ends when no light yellow liquid evaporates in the reaction system, and the light yellow solid obtained by cooling is the crude glycolide product. The yield of glycolide was 87%, the purity was 85.28%, and the coking rate of the reaction system was 11%.

Embodiment 3

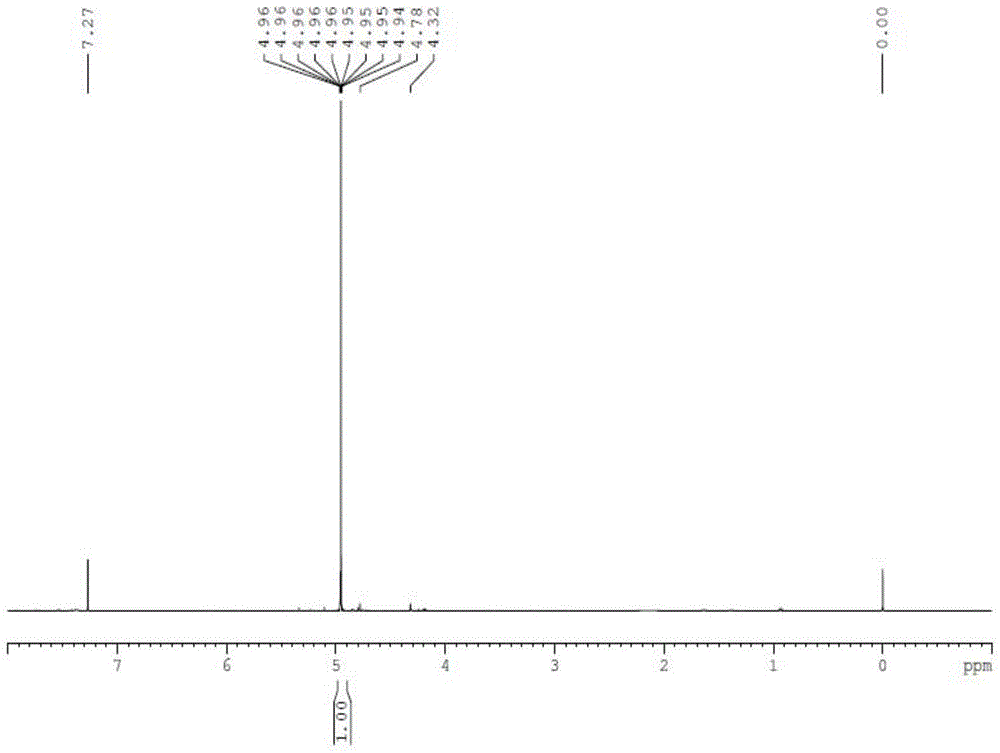

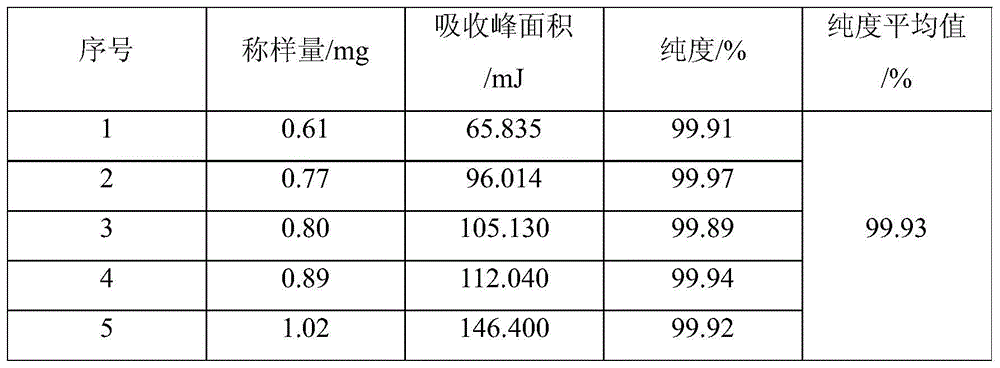

[0044] Add 200g glycolic acid oligomer (weight average molecular weight is 12000) in 500ml four-necked flask, and 0.75g catalyst Zn (acac) 2 , heated to 200° C., and decompressed to 1 kPa in a nitrogen atmosphere. During the reaction process, a light yellow liquid evaporates until the reaction ends when no light yellow liquid evaporates in the reaction system, and the light yellow solid obtained by cooling is the crude glycolide product. The yield of glycolide is 92%, the purity is 99.93%, and the coking rate of the reaction system is 1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com