Lead-acid storage battery negative electrode lead paste and preparation method thereof

A technology of lead-acid battery and negative electrode paste, applied in lead-acid battery, battery electrodes, circuits, etc., can solve problems such as unsatisfactory effects, achieve the effects of improving oxygen cycle efficiency, operating specifications, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by embodiment the present invention will be further described.

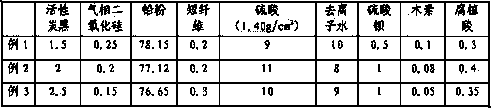

[0018] In Examples 1, 2 and 3, activated carbon black and fumed silica were added to the negative electrode paste for the test battery.

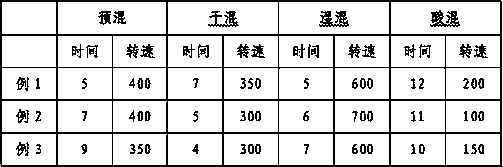

[0019] Table 1:

[0020]

[0021] In the table, the specific surface areas of activated carbon black and fumed silica are 600m 2 / g and 200m 2 / g.

[0022] The preparation method operation steps of above-mentioned negative pole lead paste are:

[0023] 1. Prepare materials: according to the mass ratio of each component in Table 1, weigh the materials and set aside;

[0024] 2. Premixing: add activated carbon black, fumed silica, barium sulfate, short fiber, lignin, humic acid and premix in the paste machine;

[0025] 3. Dry mixing: add lead powder after premixing, turn on the cooling system, and dry mix;

[0026] 4. Wet mixing: add deionized water after dry mixing, wet mixing;

[0027] 5. Acid mixing: add sulfuric acid after wet mixing, and control the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com