Substrate for power module and manufacturing method therefor

A technology of power modules and manufacturing methods, which is applied in the directions of manufacturing tools, printed circuit manufacturing, chemical instruments and methods, etc., can solve problems such as peeling of ceramic substrates and metal plates, prevent peeling, improve bonding reliability, and reduce anisotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

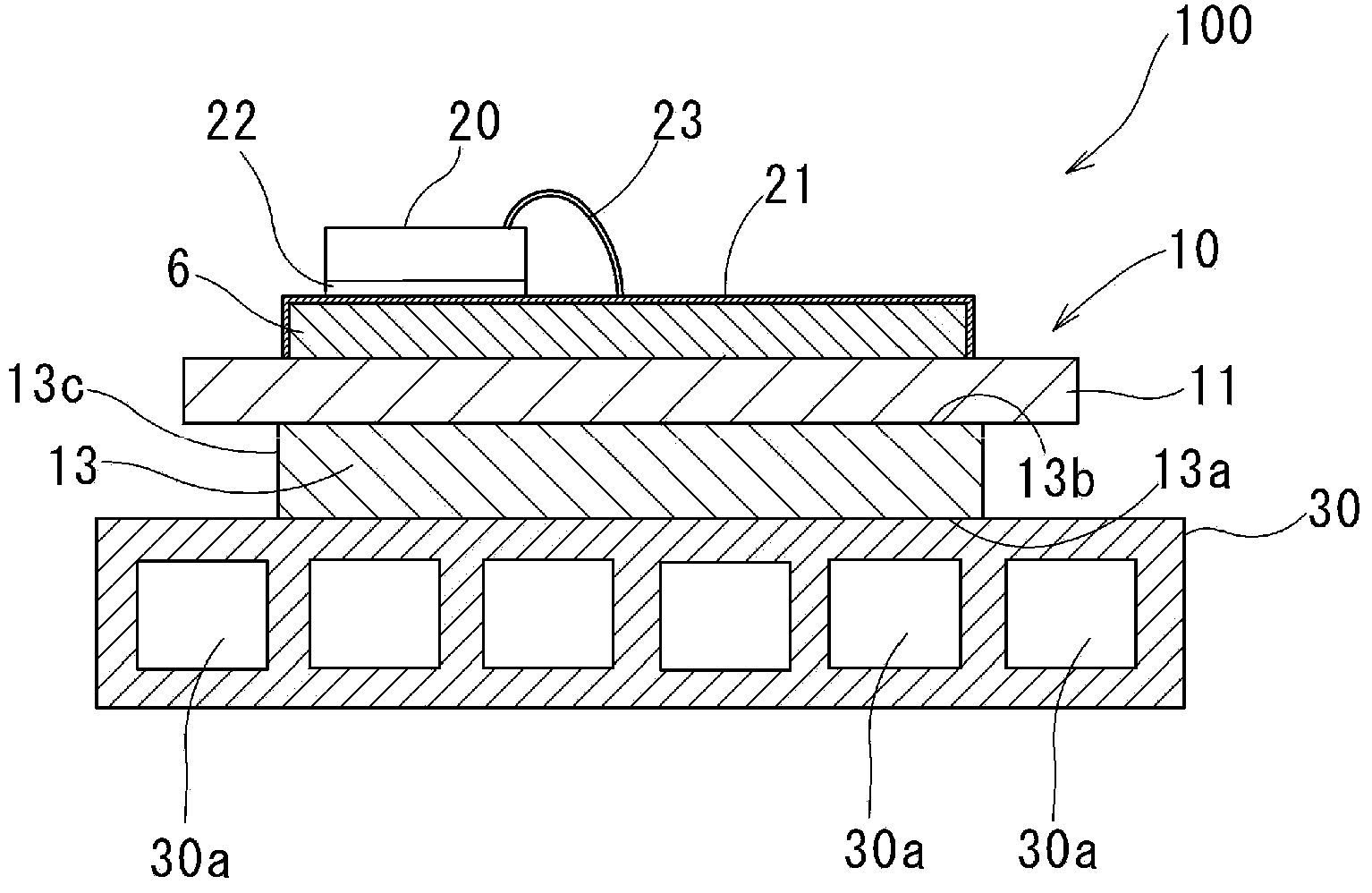

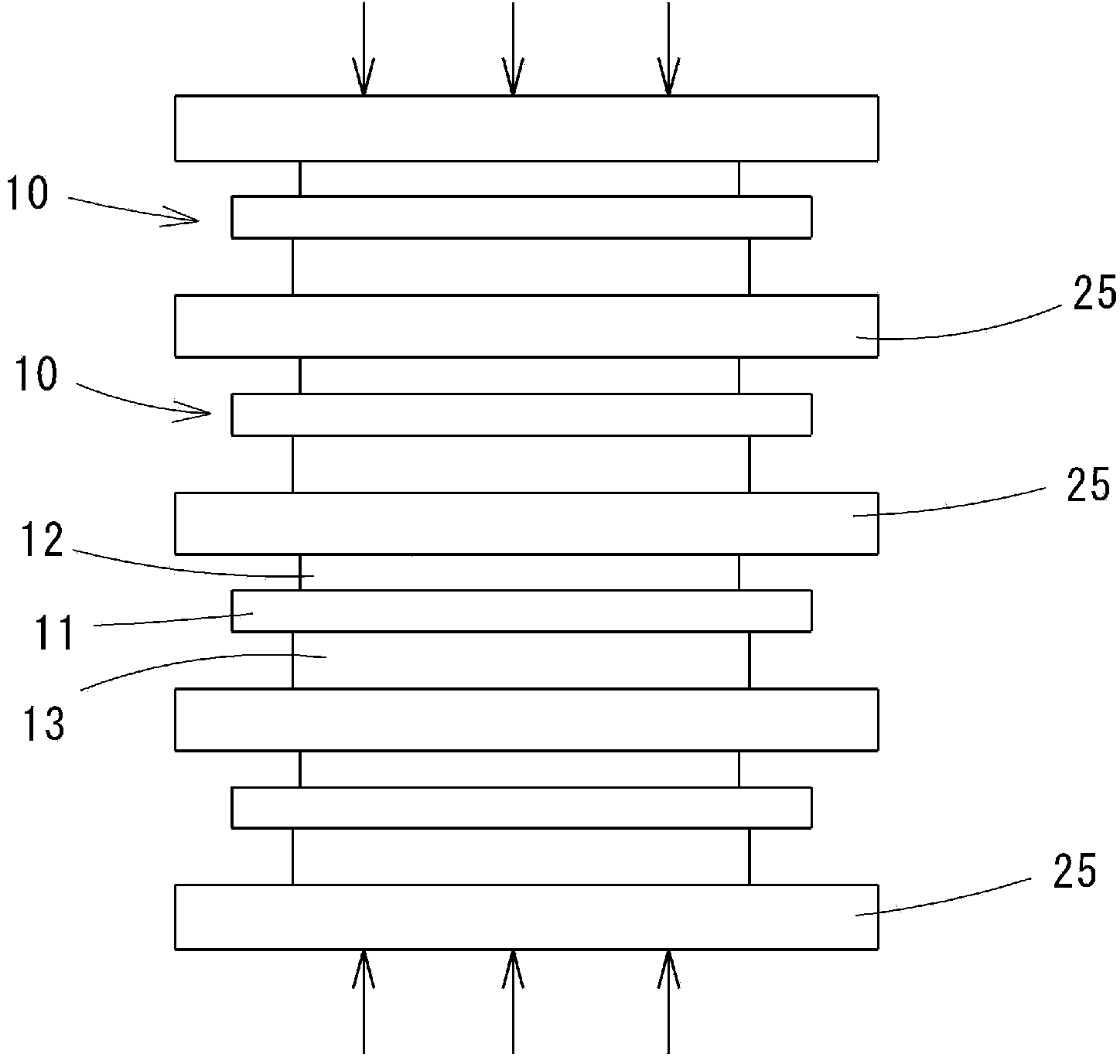

Examples

Embodiment

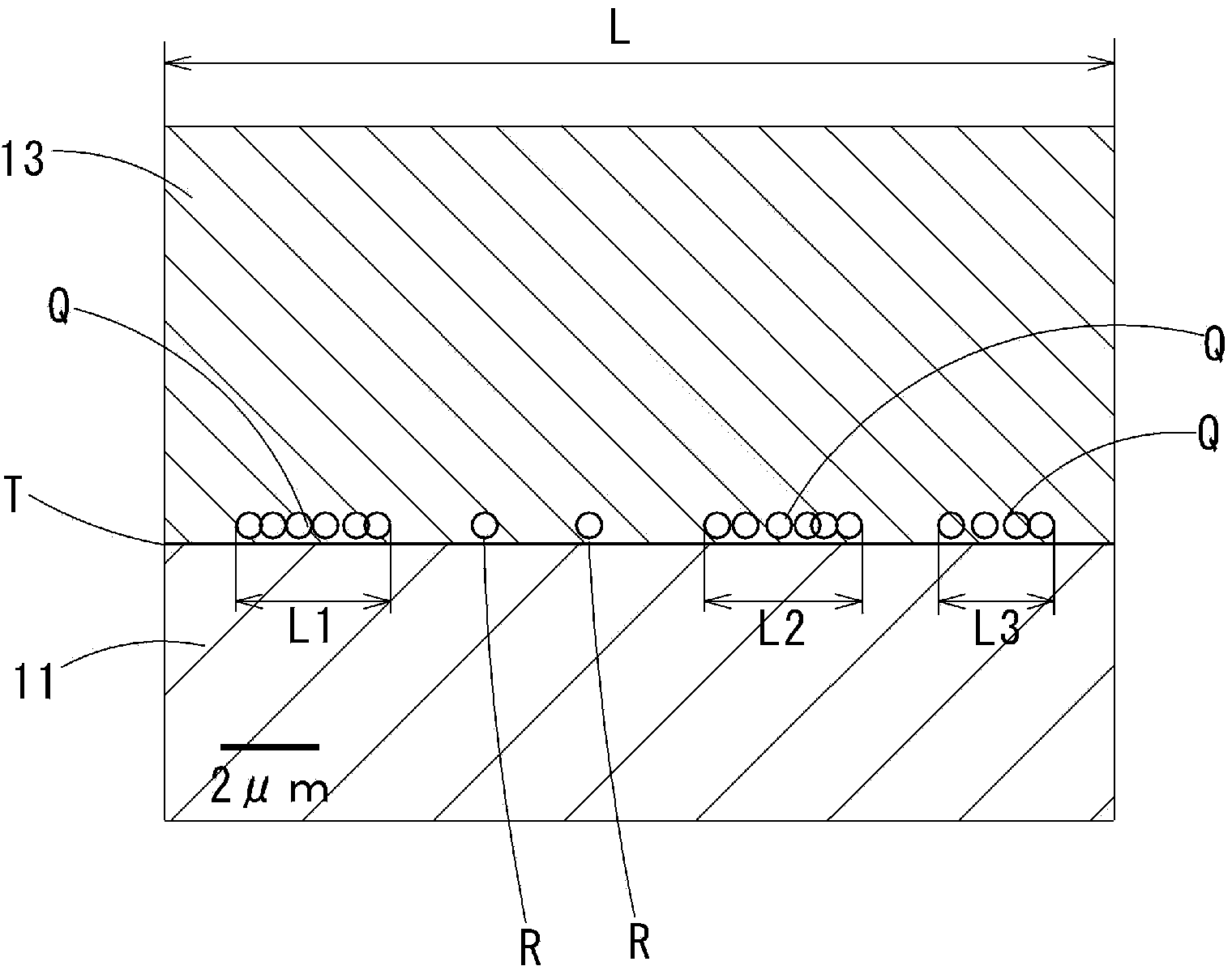

[0062] In order to confirm the effects of the present invention, the following experiments were conducted.

[0063] A rolled material made of 1N99 aluminum with a thickness of 0.6 mm was punched out into 30 mm×30 mm, etched or blasted as shown in Table 1, and the removal depth of the metal plate surface by this treatment was measured. The removal amount was calculated from the difference between the weight before treatment and the weight after treatment of the metal plate, and the removal depth was obtained from the relationship between the removal amount and the specific gravity and area of the metal plate.

[0064] Also, for the metal plate with the treated surface, the oxygen concentration is analyzed by the number of oxygen meters measured with an electron probe microanalyzer (EPMA) at an accelerating voltage of 10kV, a current of 100mA, and a beam diameter of 100μm, and X-rays in the thickness direction Photoelectron spectroscopy (XPS) was used to determine the oxide th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com