Polymer electrolyte composition, electrolyte membrane, membrane-electrode assembly and fuel cell

一种组合物、聚合物的技术,应用在固体电解质燃料电池、燃料电池、燃料电池的零部件等方向,能够解决燃料电池故障等问题,达到改善阳离子传导性、优异溶解特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

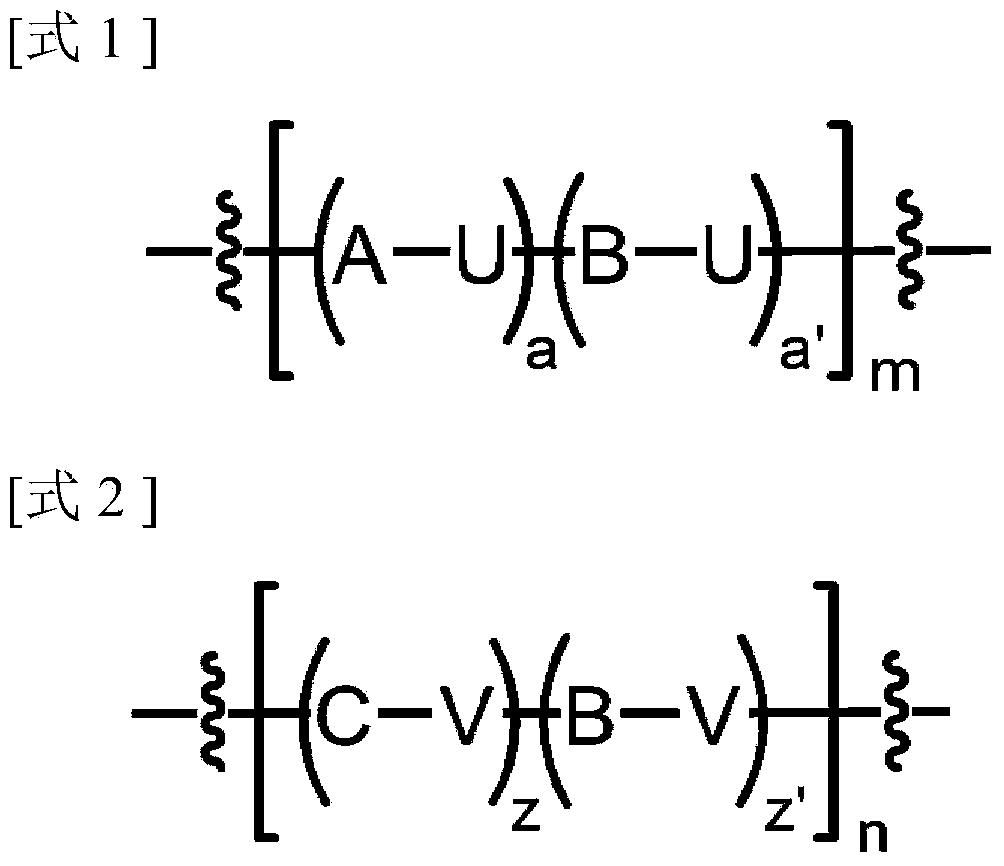

[0207] Preparation Example 1 Formation of Hydrocarbon-Based Sulfonated Block Copolymers

[0208] Hydroquinonesulfonic acid potassium salt (0.9 equiv), 4,4'-difluorobenzophenone (0.97 equiv) and 3,5-bis(4-fluorobenzoyl)phenyl (4-fluorophenyl) Methanone (0.02 eq) was placed in a 1 L round bottom flask equipped with a Dean-Stark trap and condenser in dimethyl sulfoxide (DMSO) and benzene solvent using potassium carbonate as catalyst under nitrogen atmosphere Prepare the mixture. Next, the reaction mixture was stirred in an oil bath at a temperature of 140 °C for 4 hours to allow the azeotrope to adsorb onto the molecular sieve of the Dean-Stark trap, then the mixture was removed while the benzene was refluxed, and the reaction temperature was increased to The condensation polymerization reaction was carried out at 180° C. for 20 hours. After the reaction was complete, the temperature of the reactant was reduced to 60°C, and then, 4,4'-difluorobenzophenone (0.2275 equivalents)...

preparation Embodiment 2

[0209] Preparation Example 2 Preparation of Polymer Electrolyte Composition

[0210] 38 g of dimethyl sulfoxide was prepared as a first solvent, and 2 g of water was prepared as a second solvent, which were mixed and stirred for 2 hours to prepare a heterogeneous solvent. Subsequently, 10 g of the hydrocarbon-based sulfonated block type copolymer prepared in Preparation Example 1 was dissolved in the heterogeneous solvent, filtered with a BORU glass filter (pore size 3) to remove impurities and the like, and then, prepared A polymer electrolyte composition solution was obtained.

preparation Embodiment 3

[0211] Preparation Example 3 Preparation of Electrolyte Membrane

[0212] On a clean bench, using a scraper on the horizontal plate of a film scraper, the solution prepared in Preparation Example 2 was cast on a substrate to form a polymer film, and then the film was kept at a temperature of 50° C. for 2 hours to Proceed to a gentle roast. After that, the membrane was dried in an oven set at 100° C. for 24 hours to form an electrolyte membrane including the polymer electrolyte composition prepared in Preparation Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

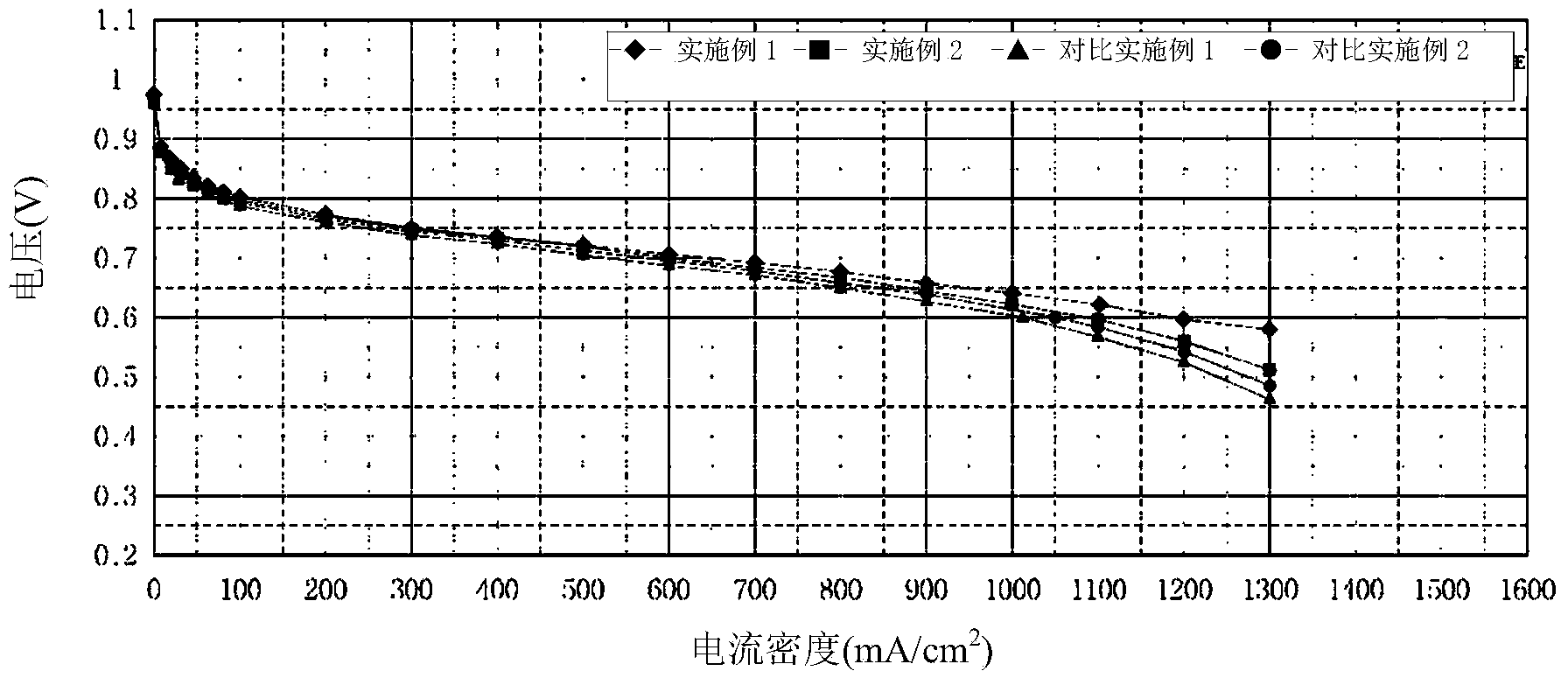

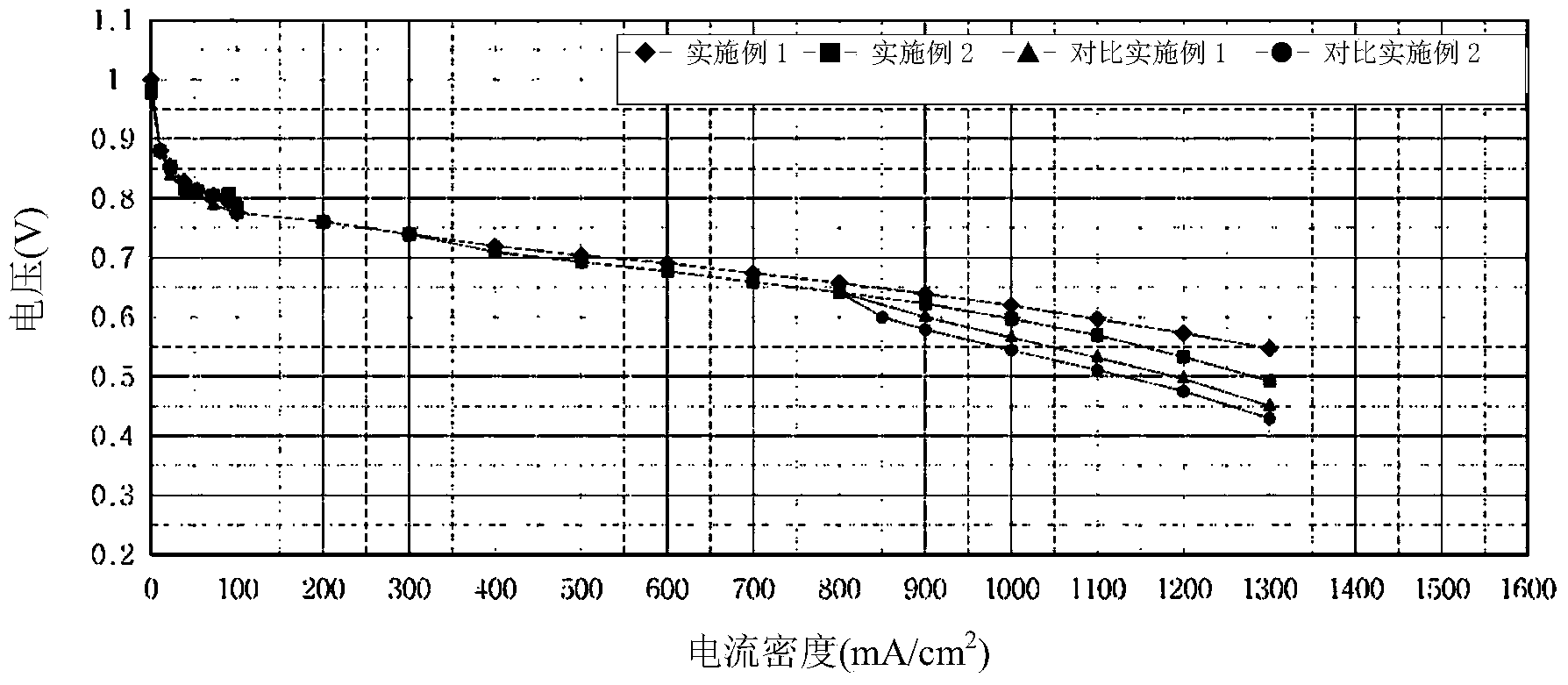

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com