Clopidogrel sulfate tablet and preparation process thereof

A technology of clopyrrole bisulfate tablet and chloropyrrole bisulfate, which is applied in the directions of pill delivery, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. Poor compliance, heavy tablets and other problems, to avoid sticking and punching problems, facilitate medication, and achieve the effect of small tablet weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

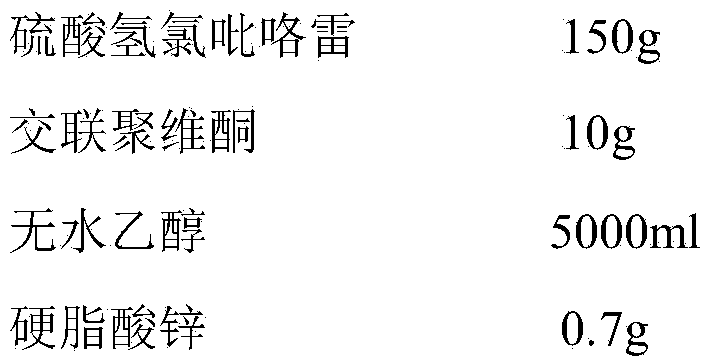

Embodiment 1

[0028]

[0029] Preparation Process:

[0030] (1) The recipe quantity takes by weighing clopyrrole hydrogen sulfate, joins in the prescription quantity dehydrated alcohol, stirs to dissolve, then adds the crospovidone crossing 100 mesh sieves of the prescription quantity, stirs and mixes evenly, and puts on the spray drier , the drying temperature is set at 55°C, the spray speed is 45ml / min, the suspension is spray-dried, and the dry matter in the receiving room is collected to prepare the clopyrrole hydrogen sulfate cross-linked povidone complex;

[0031] (2) Mix the compound obtained in step (1) with the prescribed amount of zinc stearate in a multi-sport mixer, and compress it into tablets using a rotary tablet press.

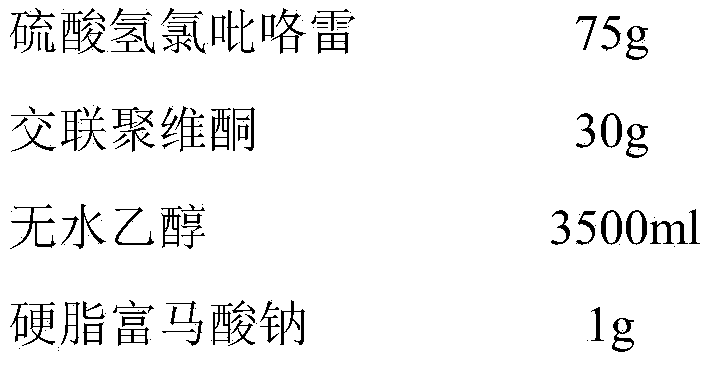

Embodiment 2

[0033]

[0034] Preparation Process:

[0035] (1) The recipe quantity takes by weighing clopyrrole hydrogen sulfate, joins in the prescription quantity dehydrated alcohol, stirs to dissolve, then adds the crospovidone crossing 100 mesh sieves of the prescription quantity, stirs and mixes evenly, and puts on the spray drier , the drying temperature is set at 50°C, the spray speed is 40ml / min, the suspension is spray-dried, and the dry matter in the receiving room is collected to prepare the clopyrrole hydrogen sulfate cross-linked povidone compound;

[0036] (2) Mix the compound obtained in step (1) with the prescribed amount of sodium stearyl fumarate in a multi-motion mixer, and press into tablets with a rotary tablet press.

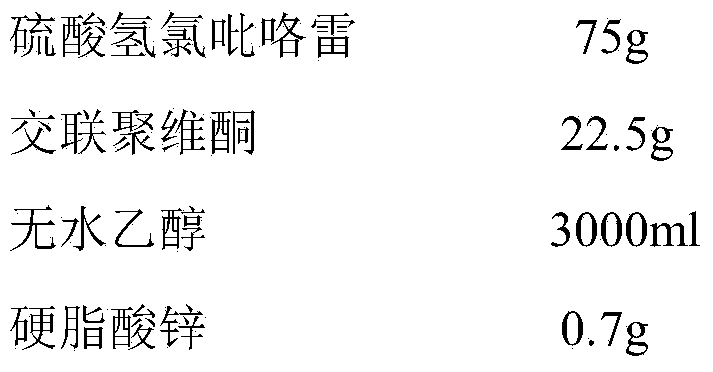

Embodiment 3

[0038]

[0039] Preparation Process:

[0040] (1) The recipe quantity takes by weighing clopyrrole hydrogen sulfate, joins in the prescription quantity dehydrated alcohol, stirs to dissolve, then adds the crospovidone crossing 80 mesh sieves of the recipe quantity, stirs and mixes evenly, on the spray drier , the drying temperature is set at 50°C, the spray speed is 40ml / min, the suspension is spray-dried, and the dry matter in the receiving room is collected to prepare the clopyrrole hydrogen sulfate cross-linked povidone complex;

[0041] (2) Mix the compound obtained in step (1) with the prescribed amount of zinc stearate in a multi-sport mixer, and compress it into tablets using a rotary tablet press.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com