One-step preparation method and application of supported platinum-based multi-metal catalysts

A multi-metal catalyst, supported technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of uniform dispersion of metal particles and preparation process Complicated and complicated issues, to achieve the effect of being suitable for large-scale production, environment-friendly, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Pt 3 PD 1 / XC-72R(40wt%)

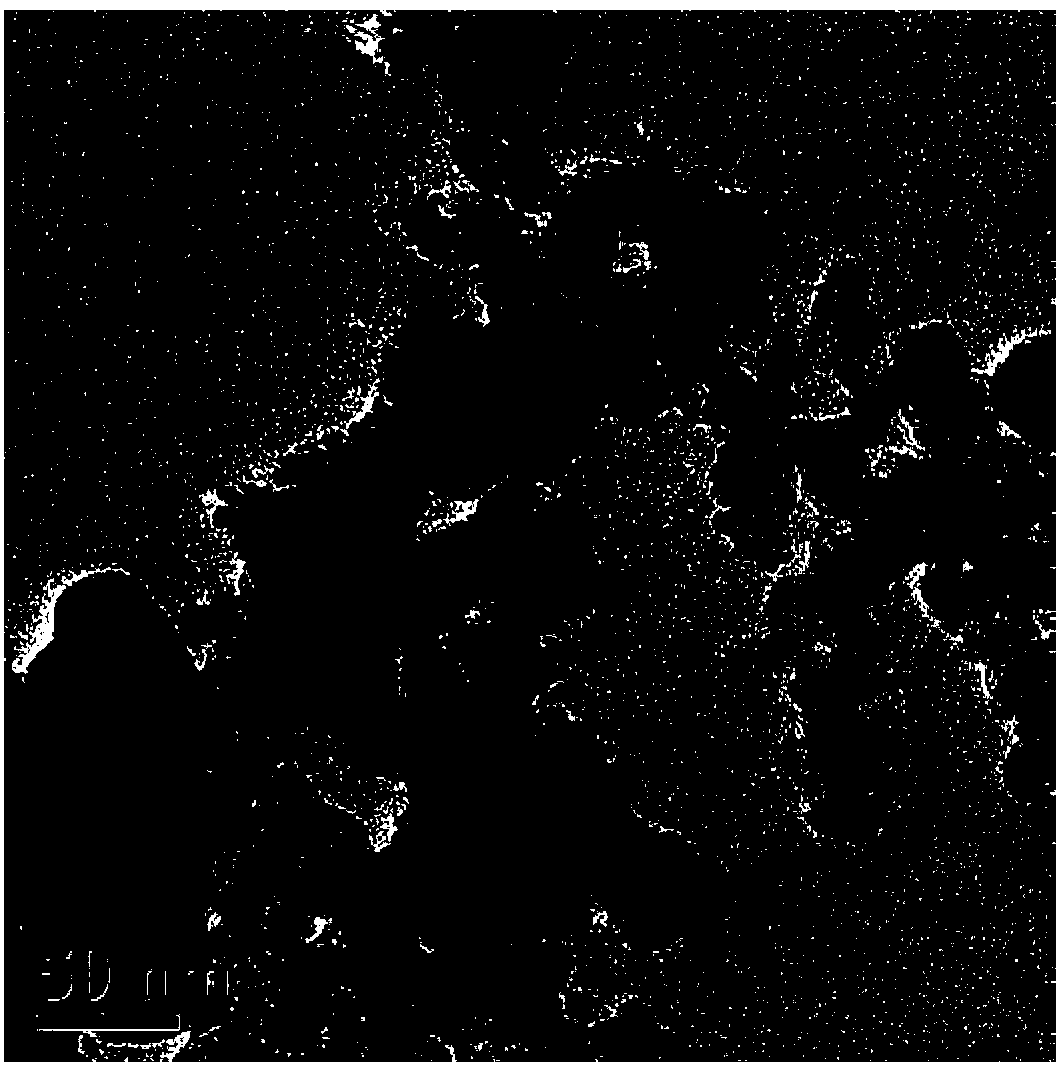

[0048] Ultrasonic disperse Vulcan XC-72R carbon powder (60mg) in 60mL aqueous solution, add 10mL ascorbic acid aqueous solution (150mM) and 10mL polyoxyethylene lauryl ether aqueous solution (1mM) under stirring; after stirring at room temperature for 10min, add to the above reaction system Add 11.6mL K 2 PdCl 4 and K 2 PtCl 4 The mixed aqueous solution, where K 2 PdCl 4 and K 2 PtCl 4 The concentrations in this mixed solution were 5 mM and 15 mM, respectively. After reacting for 1 hour, use 2L of deionized water to filter and wash for many times, and then dry in a vacuum oven at 60°C for 10 hours to obtain Pt 3 PD 1 / XC-72R (40wt%) catalyst. figure 1 for the obtained Pt 3 PD 1 / XC-72R (40wt%) catalyst transmission electron microscope (TEM). Depend on figure 1 It can be seen that the Pt-Pd bimetallic nanocatalyst grows on the surface of the support without obvious particle aggregation and scattering. The obtained ca...

Embodiment 2

[0049] Example 2: Pt 1 PD 1 / XC-72R(40wt%)

[0050] Ultrasonic disperse Vulcan XC-72R carbon powder (60mg) in 60mL aqueous solution, add 10mL ascorbic acid aqueous solution (150mM) and 10mL polyoxyethylene lauryl ether aqueous solution (1mM) under stirring; after stirring at room temperature for 10min, add to the above reaction system Add 13.2mL of K 2 PdCl 4 and K 2 PtCl 4 The mixed aqueous solution, where K 2 PdCl 4 and K 2 PtCl 4 The concentrations in this mixed solution were 10 mM and 10 mM, respectively. After reacting for 1 hour, use 2L of deionized water to filter and wash for many times, and then dry in a vacuum oven at 60°C for 10 hours to obtain Pt 1 PD 1 / XC-72R (40wt%) catalyst. Figure 4 for the obtained Pt 1 PD 1 / XC-72R (40wt%) catalyst transmission electron microscope (TEM). Depend on Figure 4 It can be seen that the Pt-Pd bimetallic nanocatalysts grow in situ on the surface of the support without obvious particle aggregation and scattering.

Embodiment 3

[0051] Example 3: Pt 9 PD 1 / XC-72R(40wt%)

[0052] Ultrasonic disperse Vulcan XC-72R carbon powder (60mg) in 60mL aqueous solution, add 10mL ascorbic acid aqueous solution (150mM) and 10mL polyoxyethylene lauryl ether aqueous solution (1mM) under stirring; after stirring at room temperature for 10min, add to the above reaction system Add 10.64mL of K 2 PdCl 4 and K 2 PtCl 4 The mixed aqueous solution, where K 2 PdCl 4 and K 2 PtCl 4 The concentrations in this mixed solution were 2 mM and 18 mM, respectively. After reacting for 1 hour, use 2L of deionized water to filter and wash for many times, and then dry in a vacuum oven at 60°C for 10 hours to obtain Pt 9 PD 1 / XC-72R (40wt%) catalyst. Figure 5 for the obtained Pt 9 PD 1 / XC-72R (40wt%) catalyst transmission electron microscope (TEM). Depend on Figure 5 It can be seen that the Pt-Pd bimetallic nanocatalysts grow in situ on the surface of the support without obvious particle aggregation and scattering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com