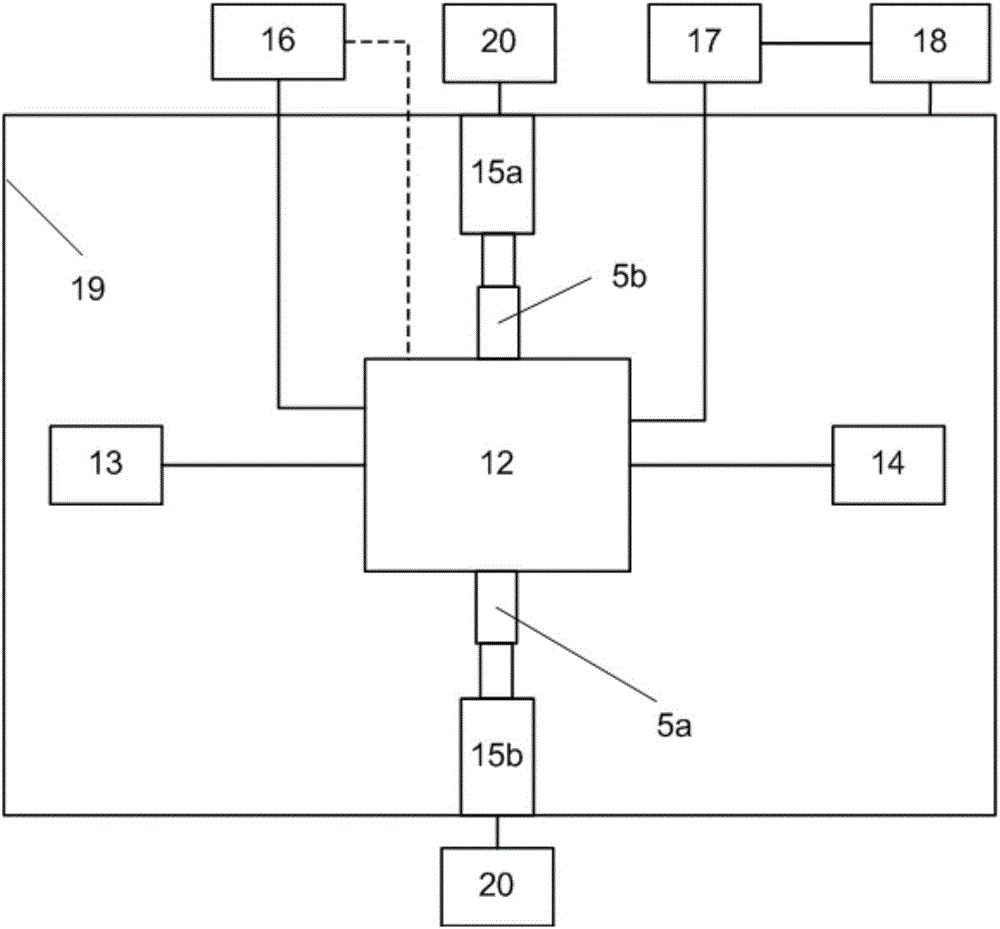

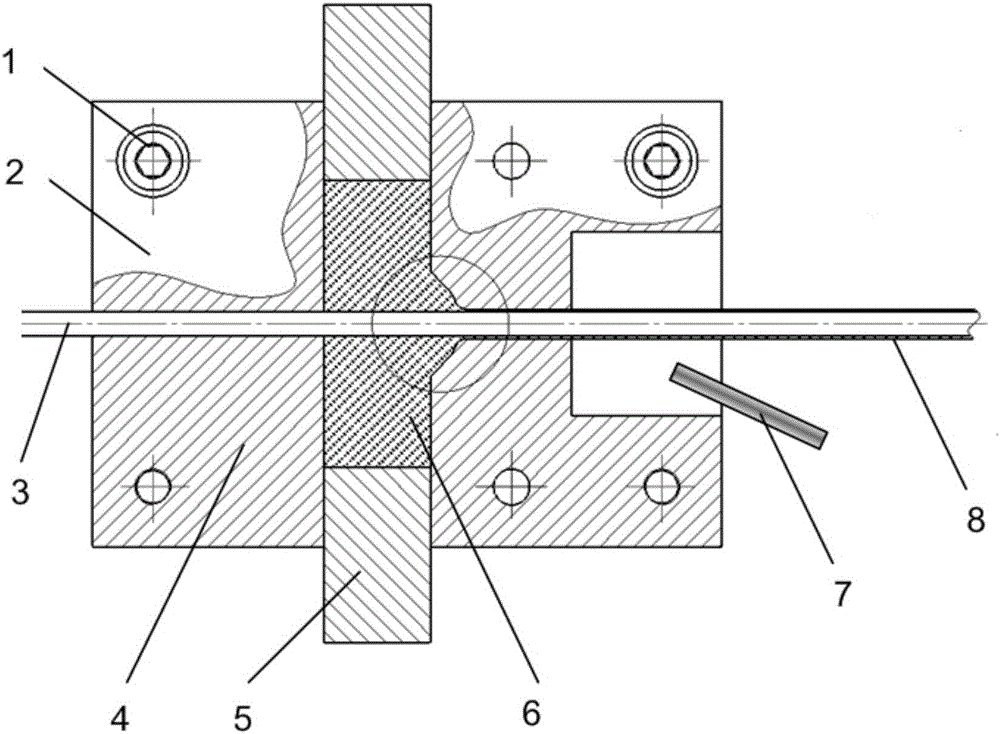

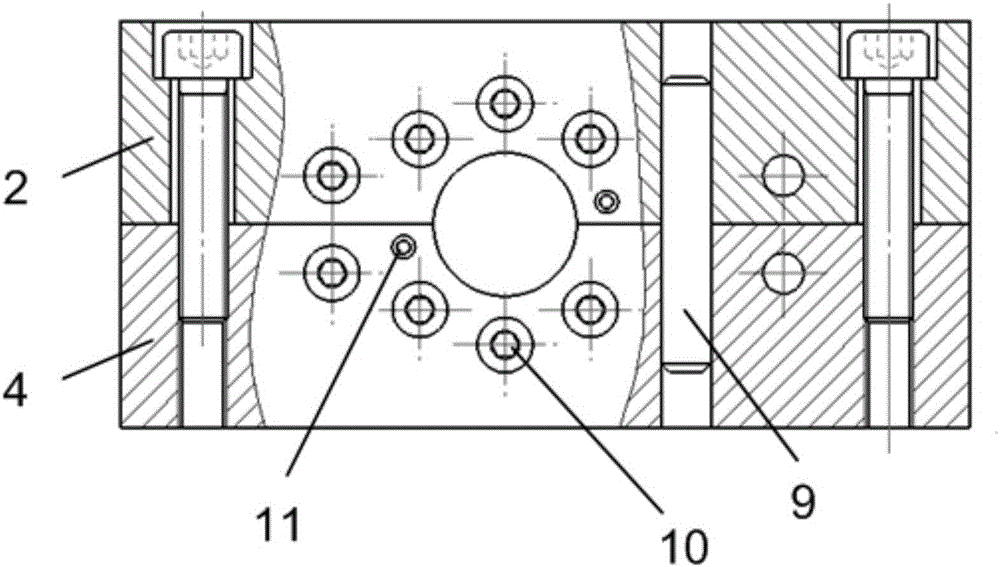

Device and process for coating wire rod by multi-directional extrusion of amorphous alloy

An amorphous alloy, multi-directional extrusion technology, applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of complex mold structure, high processing cost, low mold life, etc., to ensure processing accuracy and Surface quality, low processing cost, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The material of the wire is copper wire with a diameter of 1 mm; the amorphous alloy coated on the outer layer of the copper wire is Zr58.5Cu15.6Ni12.8Al10.3Nb2.8. The glass transition temperature and crystallization temperature of the amorphous alloy Zr58.5Cu15.6Ni12.8Al10.3Nb2.8 are 385°C and 470°C respectively. When the heating temperature is 405°C, it can be kept for 30 minutes without crystallization. Meet the requirements of the coating process. When cladding the amorphous alloy, the heating temperature of the extrusion cylinder and the shaping sleeve is controlled at 403°C to 407°C by a temperature controller. The traction force used during cladding is 100N, and the thickness of the cladding amorphous alloy is 0.1mm. The protective gas is nitrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com