Emulsion explosive waste treatment device

A technology for emulsifying waste explosives and treatment devices, which is applied to explosives, explosives processing equipment, offensive equipment and other directions, can solve the problems of substandard explosives quality, limited treatment efficiency, low temperature of wastes, etc., and achieves equipment that is intrinsically safe, reliable and structurally stable. Simple and practical, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

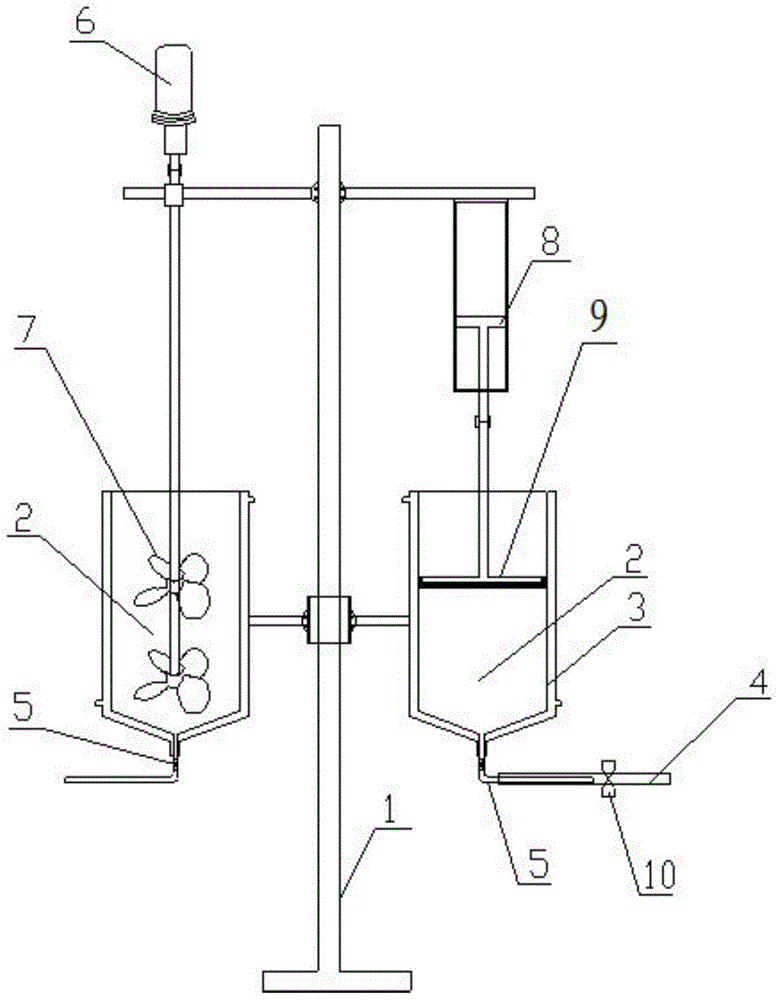

[0017] Such as figure 1 As shown, the emulsion explosive waste treatment device includes a cross bar, a bracket 1, a valve discharge pipe 5, a driver 8, and a piston 9. It also includes an open material cylinder 2, an outer cylinder liner 3, a motor 6, and a stirring paddle. 7. Two sets of open material cylinders have an outer cylinder liner 3 to form a interlayer, and the upper and lower parts of the outer cylinder liner 3 are respectively provided with a liquid inlet and a liquid outlet that are directly connected to the interlayer, which can be heated or cooled by externally connected hot or cold water in and out of the interlayer; bracket 1 The upper section is symmetrically provided with a motor 6 with a stirring paddle 7 supported by a cross bar and a driver 8 with a piston 10, and the lower section of the rotating bracket is symmetrically provided with an open material cylinder 2 with an interlayer, and the stirring paddle connected to the motor 6 7. The piston 9 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com