Luminous composition for metal halide lamp and luminous pill for metal halide lamp and preparation method thereof

A technology for luminescent pills and metal halide lamps, which is applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of rising relative color temperature of lamps, large changes in light color, rarely reaching them, etc. The effect of reducing the penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

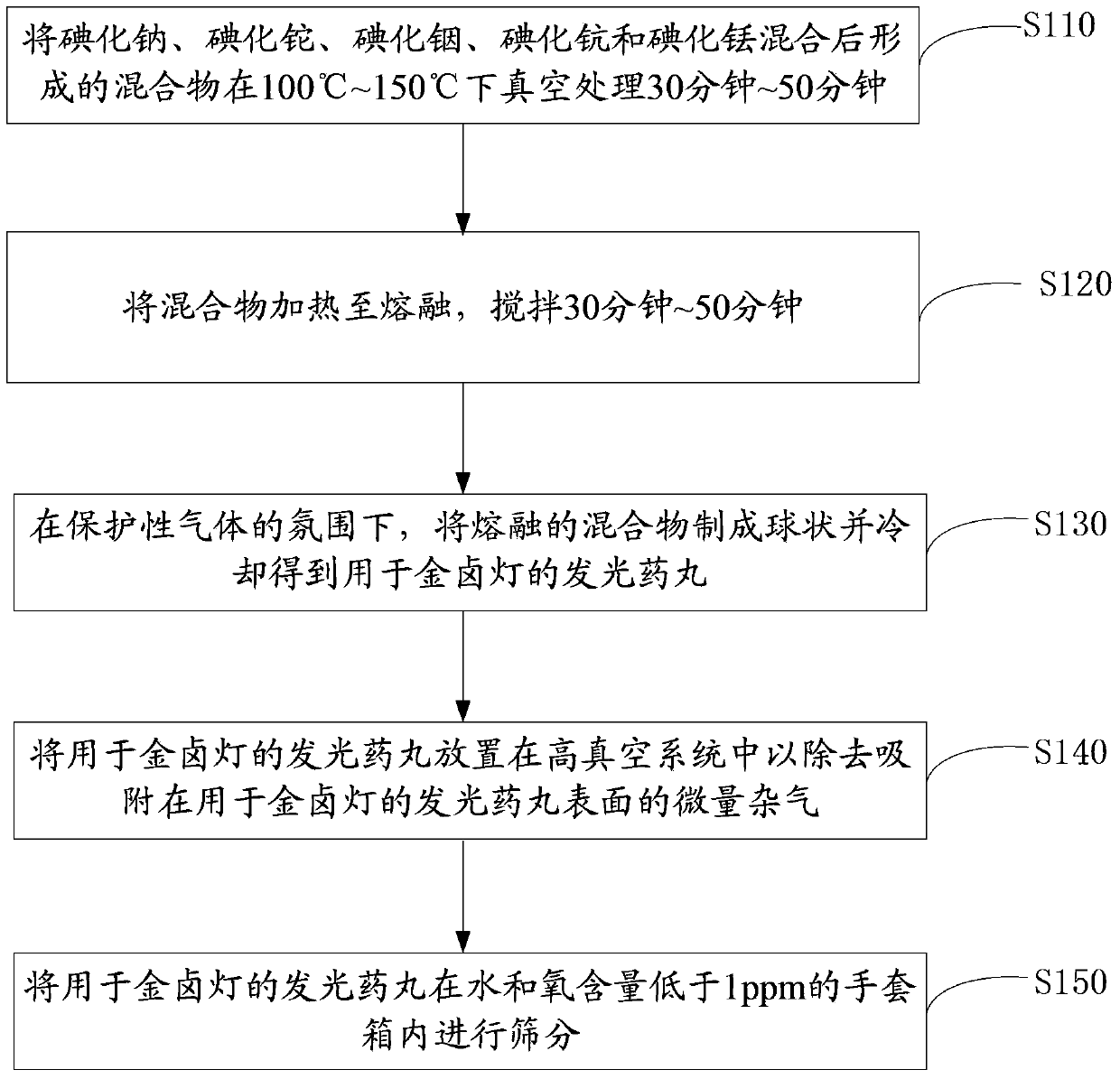

[0028] see figure 1 , a method for preparing a luminescent pill for a metal halide lamp in one embodiment, is characterized in that it includes the following steps:

[0029] Step S110 , the mixture formed by mixing sodium iodide, thallium iodide, indium iodide, scandium iodide and thulium iodide is vacuum treated at 100° C. to 150° C. for 30 minutes to 60 minutes.

[0030] The molar ratio of sodium iodide, thallium iodide, indium iodide, scandium iodide and thulium iodide is 0.3~1.4:1.0×10 -3 ~1.4×10 -2 : 2.0×10 -3 ~5.0×10 -3 : 0.02~0.40: 2.0×10 -3 ~1.2×10 -2 .

[0031] Preferably, the mixture is placed in a quartz container with a nozzle for vacuum treatment.

[0032] Step S120, heating the mixture until melting, and stirring for 30 minutes to 50 minutes.

[0033] In this step, scandium iodide, thulium iodide and sodium iodide form a complex with a lower melting point under high temperature conditions.

[0034] Step S130 , under a protective gas atmosphere, the molte...

Embodiment 1

[0045] A luminescent composition for metal halide lamps, composed of sodium iodide, thallium iodide, indium iodide, scandium iodide and thulium iodide complexed, sodium iodide, thallium iodide, indium iodide, iodine The molar ratio composition of scandium chloride and thulium iodide is: 0.3:1.4×10 -2 :5.0×10 -3 :0.02:2.0×10 -3 .

[0046]Mix the above-mentioned luminescent composition for metal halide lamps uniformly to form a mixture, then place it in a quartz container with a nozzle, perform pre-vacuum treatment at 100°C for 60 minutes, then slowly heat until the mixture melts, stir for 50 minutes, and melt the molten mixture Sprayed from the nozzle, the molten droplets are rapidly cooled and solidified into balls in the process of high-purity argon mass transfer. Then the obtained product is further removed the trace impurities adsorbed on the surface of the ball under the high vacuum system of the molecular pump, and the 2 O and O 2 Sieve in a glove box with a content ...

Embodiment 2

[0050] A luminescent composition for metal halide lamps, composed of sodium iodide, thallium iodide, indium iodide, scandium iodide and thulium iodide complexed, sodium iodide, thallium iodide, indium iodide, iodine The molar ratio composition of scandium chloride and thulium iodide is: 0.6:1.0×10 -2 :3.0×10 -3 :0.04:6.0×10 -3 .

[0051] Mix the above-mentioned luminescent composition for metal halide lamps uniformly to form a mixture, then place it in a quartz container with a nozzle, perform pre-vacuum treatment at 120°C for 50 minutes, then slowly heat until the mixture melts, and stir for 40 minutes, and the molten mixture Sprayed from the nozzle, the molten droplets are rapidly cooled and solidified into balls in the process of high-purity argon mass transfer. Then the obtained product is further removed the trace impurities adsorbed on the surface of the ball under the high vacuum system of the molecular pump, and the 2 O and O 2 Sieve in a glove box with a content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com