Carbon fiber surface treatment method and treatment device

A technology of surface treatment and treatment device, applied in the direction of anodizing, cells, plating tanks, etc., can solve the problems of poor washing effect, easy damage to carbon filaments, high water consumption, etc., to improve the interlayer shear strength, easy to wash The effect of clean, less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

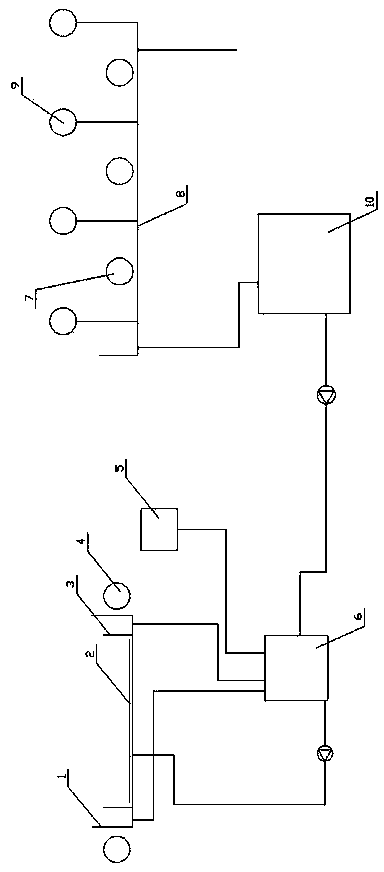

Method used

Image

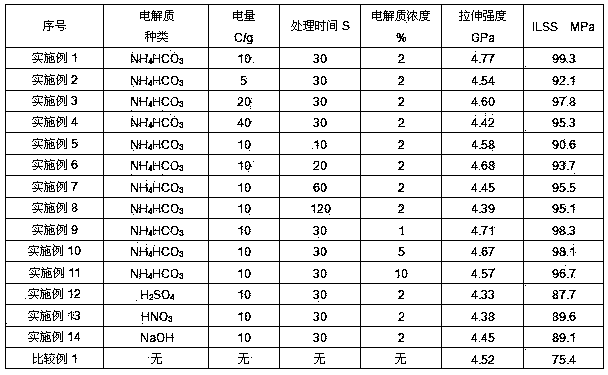

Examples

Embodiment 1

[0020] Embodiment 1, a kind of carbon fiber surface treatment method, its steps are as follows:

[0021] (1) Pour the ammonium bicarbonate solution with a mass concentration of 2% into the electrolytic cell, pass the dry-sprayed wet-spun carbon fiber tow after high-temperature carbonization through the electrolytic cell, and perform electrolysis at room temperature. The electrolytic treatment time is 30S, and the electrolytic power 10C / g;

[0022] (2) The carbon fiber tow after electrolysis enters the washing tank and is washed with deionized water. The washing temperature is 20°C and the washing time is 160S;

[0023] (3) The washed carbon fiber tow is dried by contact drying, which is heated by a steam drying cylinder. The surface temperature of the drying cylinder is 120°C, the time is 80S, and the steam pressure is 0.2MPa.

Embodiment 2

[0024] Embodiment 2, a kind of carbon fiber surface treatment method, its steps are as follows:

[0025] (1) Pour the ammonium bicarbonate solution with a mass concentration of 2% into the electrolytic cell, pass the dry-sprayed wet-spun carbon fiber tow after high-temperature carbonization through the electrolytic cell, and perform electrolysis at room temperature. The electrolytic treatment time is 30S, and the electrolytic power 5C / g;

[0026] (2) The carbon fiber tow after electrolysis enters the washing tank and is washed with deionized water. The washing temperature is 30°C and the washing time is 150S;

[0027] (3) The washed carbon fiber tow is dried by a contact drying method, which is heated by a steam drying cylinder. The surface temperature of the drying cylinder is 130°C, the time is 100S, and the steam pressure is 0.2MPa.

Embodiment 3

[0028] Embodiment 3, a kind of carbon fiber surface treatment method, its steps are as follows:

[0029] (1) Pour the ammonium bicarbonate solution with a mass concentration of 2% into the electrolytic cell, pass the dry-sprayed wet-spun carbon fiber tow after high-temperature carbonization through the electrolytic cell, and perform electrolysis at room temperature. The electrolytic treatment time is 30S, and the electrolytic power 20C / g;

[0030] (2) The carbon fiber tow after electrolysis enters the washing tank and is washed with deionized water. The washing temperature is 40°C and the washing time is 140S;

[0031] (3) The washed carbon fiber tow is dried by a contact drying method, which is heated by a steam drying cylinder. The surface temperature of the drying cylinder is 130°C, the time is 90S, and the steam pressure is 0.2MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com