Perpetual motion steam-driving machine

A steam engine and motive technology, applied to engine components, machines/engines, non-variable engines, etc., can solve the problems of reduced air propulsion, reduced air compression ratio, ignoring the jack principle, etc., to reduce energy consumption , The air compression ratio is increased, and the effect of improving air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

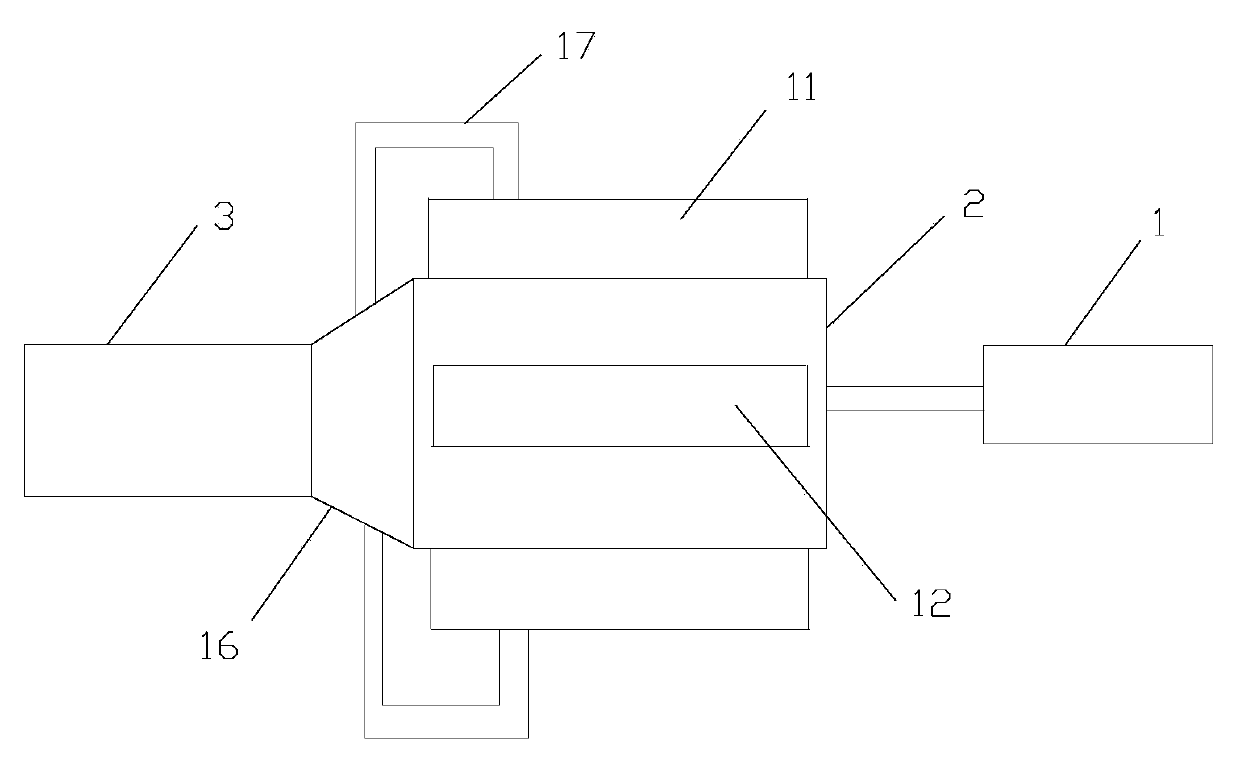

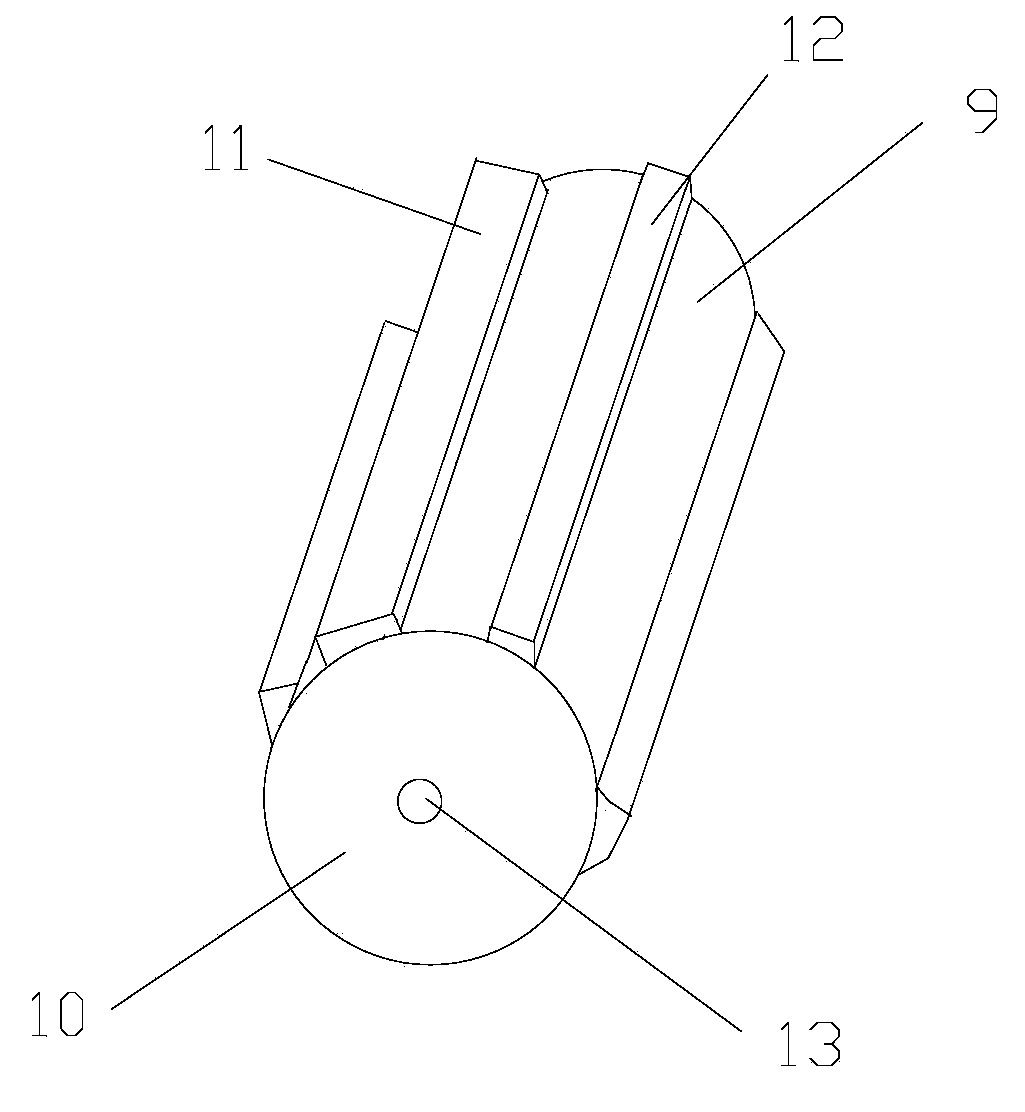

[0046] like figure 1 As shown, the perpetual motion steam motor in this embodiment includes a starter motor 1, a compressor 3 and a steam motor 2, wherein the starter motor 1 is used to assist starting of the compressor 3 and the steam motor 2, The compressor 3 is used to compress the inhaled air, and transfer the generated compressed air energy to the steam motor 2, and the steam motor is used to convert the compressed air energy into mechanical energy, and transfer the generated mechanical energy to the Compressor 3.

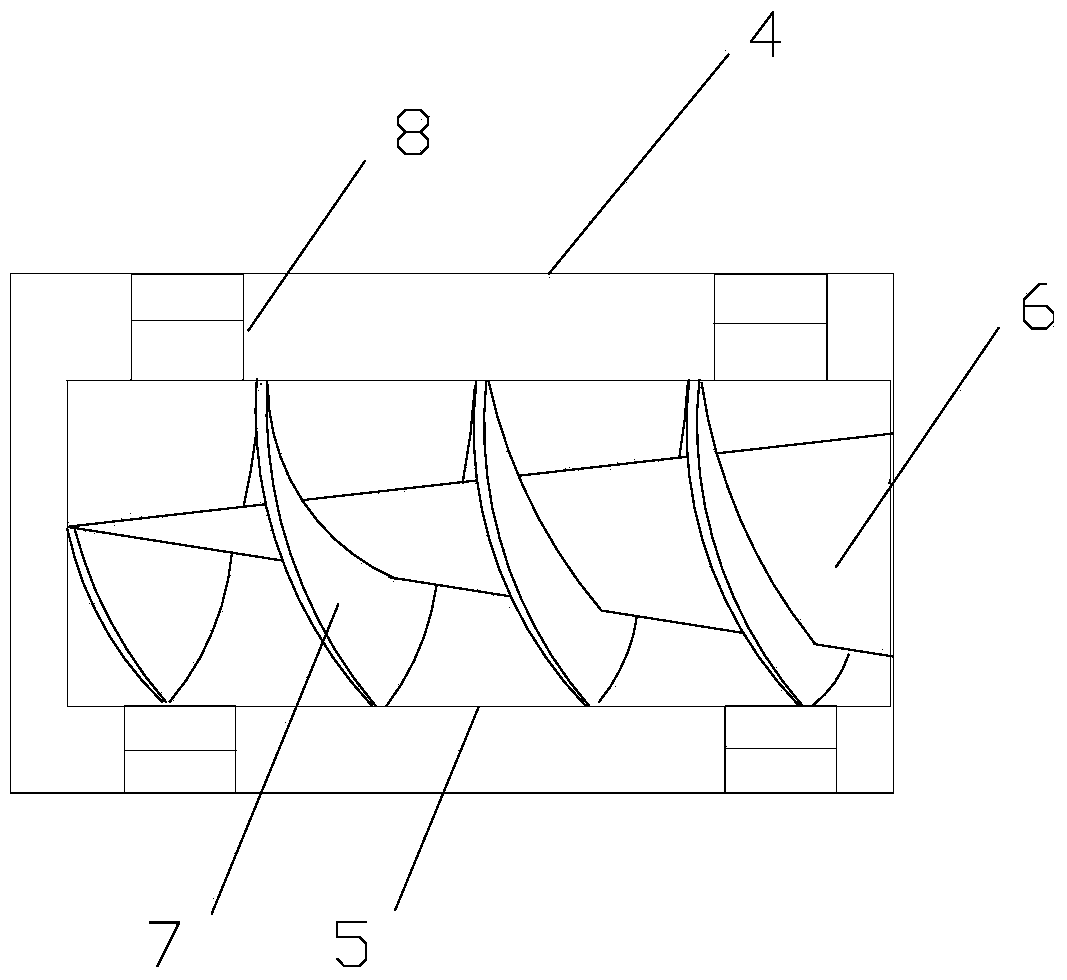

[0047] like figure 2 As shown, the compressor 3 includes a casing 4 and an air compression cylinder arranged in the casing 4, and the air compression cylinder includes an air cylinder 5 and a fan shaft arranged in the air cylinder 5, so The fan shaft includes a conical shaft 6 arranged on the central line of the gas cylinder and a number of fan 7 that surrounds the conical shaft 6 counterclockwise, and several of the fan 7 are twisted in a helical shape an...

Embodiment 2

[0076] The perpetual steam motor in this embodiment has basically the same structure as that in Embodiment 1, including a starter motor, a compressor and a steam motor, wherein the starter motor performs intermittent startup, and the compressor is used to compress the inhaled air , and transmit the generated compressed air energy to the steam motor, and the steam motor is used to convert the compressed air energy into mechanical energy, and transmit the generated mechanical energy to the compressor.

[0077] The compressor includes a casing and an air compression cylinder arranged in the casing, the air compression cylinder includes an air cylinder and a fan shaft arranged in the air cylinder, and the fan shaft includes a The tapered shaft on the central line of the gas cylinder and a number of rotary fans surrounding the tapered shaft in the counterclockwise direction, the several rotary fans are twisted in a spiral shape and evenly arranged on the tapered shaft, and The fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com