Method for measuring phosphorus content in chromite

A determination method, the technology of chromite, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of wasting reagents and long process, and achieve the effect of stable results, simple method and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a kind of content determination method of phosphorus in chromite ore, its steps are as follows:

[0023] (1) Weigh 0.2g of chromite sample, accurate to 0.0001g, place it in a corundum crucible, add 1.8g of sodium peroxide and mix well, then cover with 0.4g of sodium peroxide, place it in a muffle furnace at 700°C, and keep it for 3 minutes ;

[0024] (2) Take it out, put it in a beaker after cooling, add 80mL of hot water at 70°C to extract the melt, wash out the crucible, filter it with medium-speed filter paper, and wash the precipitate several times with sodium hydroxide solution; the mass concentration of sodium hydroxide is 18g / L;

[0025] (3) Acidify the precipitate with 10mL of 70°C hot hydrochloric acid solution, wash twice with 70°C hot water, and transfer to a volumetric flask; the volume ratio of hydrochloric acid to water in the hydrochloric acid solution is 1:0.8;

[0026] (4) Dispense 5mL of the test solution into a volumetric flask, add w...

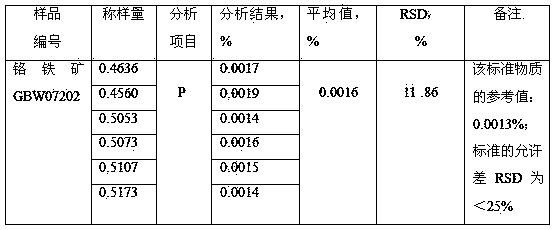

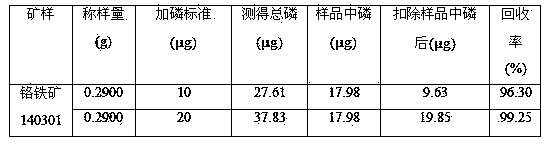

Embodiment 2

[0029] Embodiment 2, a kind of content determination method of phosphorus in chromite ore, its steps are as follows:

[0030] (1) Weigh 0.5g of chromite sample, accurate to 0.0001g, place it in a corundum crucible, add 2.2g of sodium peroxide and mix well, then cover with 0.6g of sodium peroxide, place it in a muffle furnace at 750°C, and keep it for 5 minutes ;

[0031] (2) Take it out, put it in a beaker after cooling, add 120mL of 80°C hot water to extract the melt, wash out the crucible, filter it with medium-speed filter paper, and wash the precipitate several times with sodium hydroxide solution; the mass concentration of sodium hydroxide is 22g / L;

[0032] (3) Acidify the precipitate with 10mL of 80°C hot hydrochloric acid solution, wash with 80°C hot water three times, and transfer it to a volumetric flask; the volume ratio of hydrochloric acid to water in the hydrochloric acid solution is 1: 1.5;

[0033] (4) Dispense 20mL of the test solution into a volumetric fla...

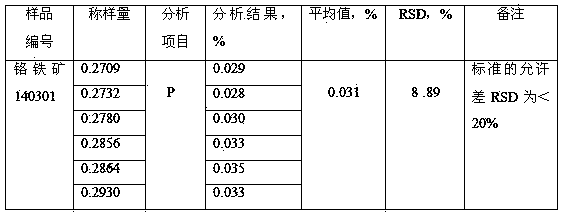

Embodiment 3

[0036] Embodiment 3, a kind of content determination method of phosphorus in chromite ore, its steps are as follows:

[0037] (1) Weigh 0.2-0.5g of chromite sample, accurate to 0.0001g, place it in a 30mL corundum crucible, add 2g of sodium peroxide and mix well, then cover with 0.5g of sodium peroxide, and place in a muffle furnace at 720-730°C During, keep for 4min;

[0038] (2) Take it out, put it in a 250mL beaker after cooling, add 100mL of 75°C hot water to extract the melt, wash out the crucible, filter it with medium-speed filter paper, and wash the precipitate several times with sodium hydroxide solution; the mass concentration of sodium hydroxide is 20g / L;

[0039] (3) Acidify the precipitate with 10mL of hot hydrochloric acid solution at 75°C, wash with hot water for 3 times, and transfer to a 50mL volumetric flask; the hydrochloric acid is of AR grade, and the volume ratio is 1+1;

[0040] (4) Dispense 10mL of the test solution into a 50mL volumetric flask, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com