Electromagnetic shielding case based on micro metal grid and manufacturing method of electromagnetic shielding case

A technology of electromagnetic shielding cover and metal grid, applied in the direction of magnetic field/electric field shielding, electrical components, etc., can solve the problems of high cost, low processing efficiency, difficulty in large-scale consistent preparation, etc., and achieve low cost, high production efficiency, Realize the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

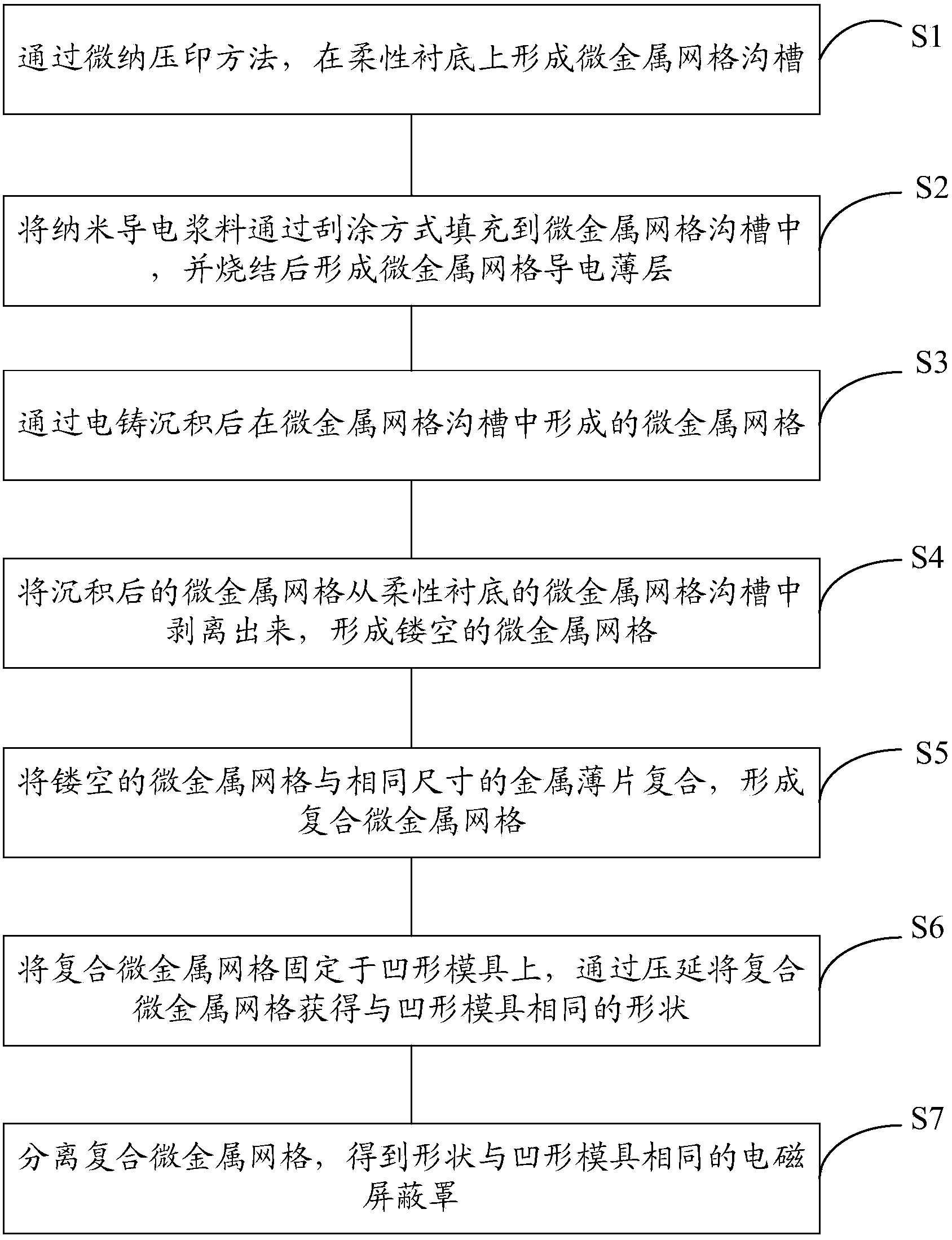

[0048] ginseng figure 1 As shown, the present invention discloses an electromagnetic shield based on micro-metal grids and a preparation method thereof, the preparation method comprising:

[0049] S1. Forming micro-metal grid grooves on the flexible substrate by micro-nano imprinting method;

[0050] S2. Filling the nano-conductive paste into the groove of the micro-metal grid by scraping, and forming a conductive thin layer of the micro-metal grid after sintering;

[0051] S3, the micro metal grid formed in the micro metal grid groove after electroforming deposition;

[0052] S4, stripping the depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com