Pickle old brine dry powder

A technology of dry powder and kimchi, which is applied in food drying, multi-step food processing, climate change adaptation, etc., to achieve the effect of convenient transportation and better flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of this kimchi mother water dry powder is:

[0018] (1) Get pickle mother water, carry out centrifugation and obtain supernatant and sediment respectively;

[0019] (2) Dilute the precipitate in step (1) with 1-10 times the mass of sterile saline, and freeze-dry the diluted liquid to obtain dry powder A;

[0020] (3) The supernatant in step (1) is concentrated, and the mass percentage of soluble solids in the concentrated solution obtained after concentration is 10%-40%. Then spray drying is used to obtain dry powder B; the temperature of spray drying is 90°C-200°C.

[0021] (4) Mix dry powder A and dry powder B at a mass ratio of 1:10-1:5000 to obtain kimchi mother water dry powder. The mass mixing ratio of dry powder A and dry powder B can also be selected as 1:1000; 1:2000; 1:3000 and so on.

[0022] A freeze-drying protectant may be added during freeze-drying, and the amount of the freeze-drying protectant added is 1%-200% of the mass perce...

Embodiment 1

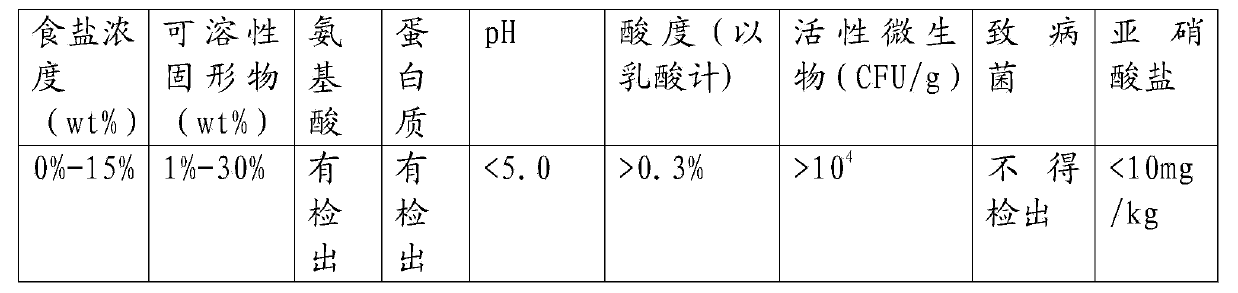

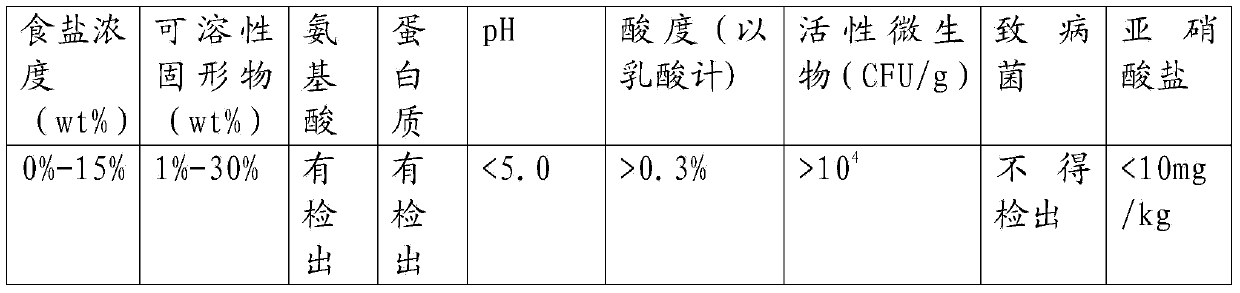

[0027] Take 1kg of fresh seasonal vegetables, wash and cut them, add 2L of 5% salt water and place them in a kimchi jar at room temperature at 20°C for soaking. After 3 days, when the kimchi brine meets the conditions required by the kimchi mother water, take out all the vegetables, auxiliary materials, and spices, and the remaining brine is the kimchi mother water; then centrifuge the kimchi mother water to obtain 3g of precipitate and supernatant Liquid 1.95kg.

[0028] The obtained precipitate was added to 30 mL of sterile saline for suspension, frozen, and then dried in a freeze dryer to obtain dry powder A1.0 g;

[0029] The supernatant was concentrated, and the soluble solids in the concentrated supernatant were 15%, and then the solids were directly spray-dried at 100°C to obtain dry powder B58.5g;

[0030] Dry powder A and dry powder B are mixed according to the mass ratio of 1:5000 to obtain pickle mother water dry powder.

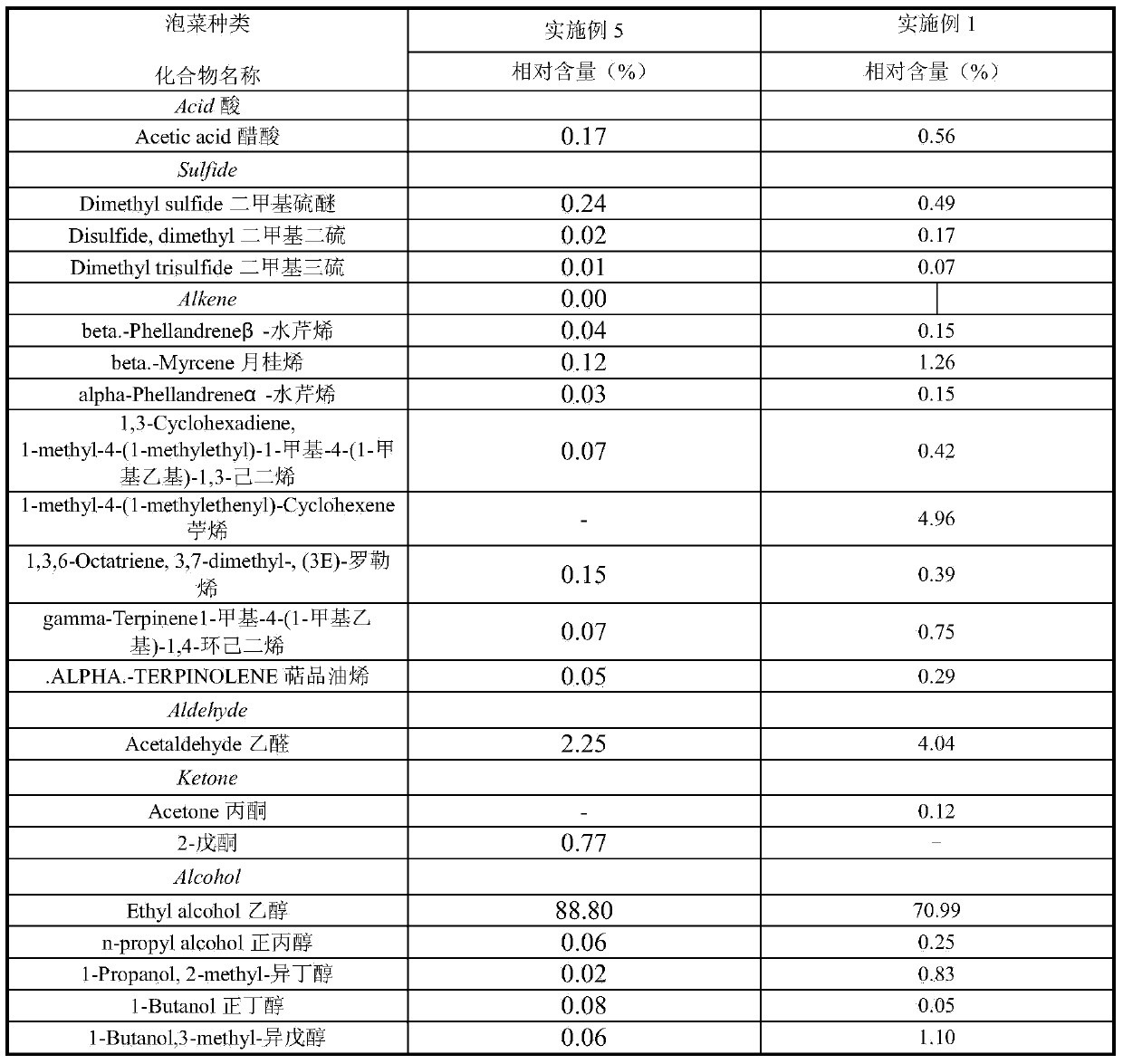

[0031] After diluting 35g of kimchi mothe...

Embodiment 2

[0033] The preparation method of dry powder A and dry powder B is as embodiment 1.

[0034] Dry powder A and dry powder B are mixed according to the mass ratio of 1:2000 to obtain pickle mother water dry powder.

[0035] Dilute 190g of kimchi mother water dry powder with 2.8L of water, add 1kg of fresh vegetables, put it in a kimchi jar for airtight fermentation after 2 days, the acidity of kimchi fermentation will reach more than 0.3%, and it can be eaten immediately. The kimchi product obtained is moderately salty and crisp Refreshing, rich ester aroma.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com