Novel powder-liquid double-chamber infusion bag and preparing method thereof

An infusion bag, a new type of technology, applied in the field of powder-liquid double-chamber infusion bags, can solve the problems of limited use and achieve better barrier properties and convenient hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

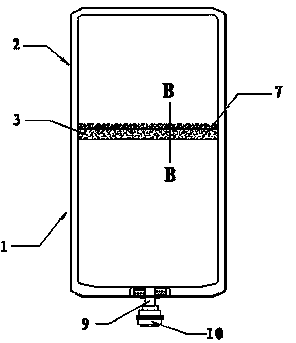

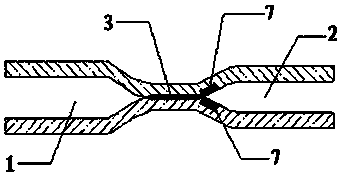

[0042] One of the preparation methods of the new powder-liquid double-chamber infusion bag (two-layer co-extrusion film material):

[0043] Step 1) The molten polypropylene pellets and the molten polyethylene pellets are made respectively by two pellet extruders, and the molten polypropylene pellets and the molten polyethylene pellets are merged in the co-extrusion equipment and then formed by the inner layer The shunt channel is co-extruded to form a film material with at least two layers of inner and outer layers, wherein the inner layer of the co-extruded film material is composed of a liquid bag inner layer made of polypropylene and a powder bag inner layer made of polyethylene, and A co-extrusion fusion part is formed at the intersection of the two; the outer layer of the co-extruded film is fed by a single polypropylene pellet extruder, and is extruded from the outer layer of the co-extrusion equipment. Determines the number of layers for the outer layer (refer to imag...

Embodiment 2

[0052] The second preparation method of the new powder-liquid double-chamber infusion bag (three-layer co-extrusion film material):

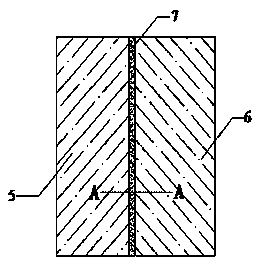

[0053] The difference between the second method and the first method is that the co-extruded film material adopts three layers, and a pellet extruder is added to extrude the molten pellets in the middle layer of polypropylene. The outer layer of the co-extrusion film is made of modified polypropylene middle layer and modified polypropylene outer layer, and the inner layer of co-extrusion film is made of modified polypropylene liquid bag inner layer and polyethylene The inner layer of the powder bag is formed, and a co-extrusion fusion part is formed at the intersection of the two; (refer to Figure 5 ).

[0054] The prepared powder-liquid double-chamber bagged ceftriaxone sodium / sodium chloride injection samples were placed in an environment of 60°C for accelerated investigation, and samples were taken at 5 days and 10 days respectively to test...

Embodiment 3

[0059] The third preparation method of the new powder-liquid double-chamber infusion bag (five-layer co-extruded film material):

[0060] The difference between the third method and the second method is that the co-extruded film material adopts five layers, and two adhesive layer pellet extruders are added to extrude two layers of adhesive layer molten pellets. The quantity determines the number of layers of the outer layer. The outer layer of the co-extrusion film material consists of two adhesive layers, a middle layer of modified polypropylene and an outer layer of modified polypropylene (refer to Figure 6 ).

[0061] The prepared powder-liquid double-chamber bagged fosfomycin sodium / glucose injection samples were placed in an environment of 60°C for accelerated investigation, and samples were taken at 5 and 10 days respectively. The test results are as follows:

[0062] Table 3 Accelerated study results of fosfomycin sodium for injection

[0063]

[0064] The result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com