A kind of preparation method of silver phosphate film

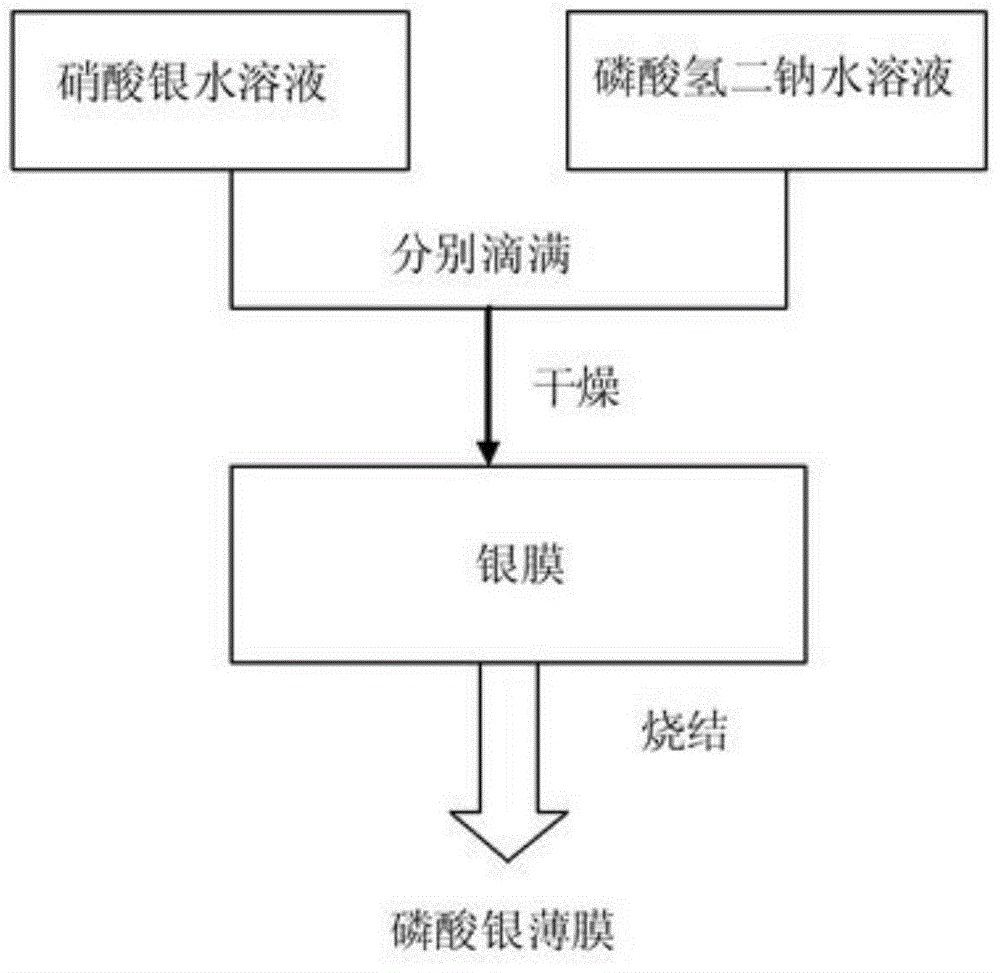

A silver phosphate film and silver phosphate technology are applied in the field of semiconductor photocatalysis and photoelectrochemical material preparation, and can solve the problems that the base photocatalyst is not easy to recover, it is not easy to realize photoelectric energy conversion, photo-splitting water for hydrogen production, etc., and achieves low cost. , easy to operate, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A silver film was deposited as a seed layer by magnetron sputtering on a glass substrate, and silver nitrate AgNO with a mass percentage concentration of 0.17% was dropped on the silver film. 3 Aqueous solution, spin-coat, dry. Then drip full mass percentage concentration is 0.14% disodium hydrogen phosphate Na 2 HPO 4 aqueous solution, and then spin-coated and dried in the same manner. Repeat the above steps 5 times to obtain silver phosphate Ag 3 PO 4 Prefabricated film. Finally, it was sintered at 400°C for 1.5h to obtain silver phosphate Ag with good binding force. 3 PO 4 film.

Embodiment 2

[0022] in TiO 2 On the glass substrate, a 100nm thick silver film is formed as a seed layer by thermal evaporation, and silver nitrate AgNO with a mass percentage concentration of 0.34% is dripped on the silver film. 3 Aqueous solution, spin-coat, dry. It is 0.28% disodium hydrogen phosphate Na to drip full mass percent concentration on it again 2 HPO 4 aqueous solution, dried at 60°C for 10 minutes, and repeated the above steps 3 times to obtain silver phosphate Ag 3 PO 4 Prefabricated film. Finally, sinter at 300°C for 1 hour to obtain silver phosphate Ag with good binding force 3 PO 4 film.

Embodiment 3

[0024] On a transparent conductive glass substrate, a 50nm silver film is formed as a seed layer by electrodeposition, and the silver film is dripped with a mass percentage concentration of 0.017% silver nitrate AgNO 3 Aqueous solution, directly dried in an oven at 60°C. It is 0.014% disodium hydrogen phosphate Na on it dripping full mass percent concentration again 2 HPO 4 The aqueous solution is directly placed in an oven at 60°C to dry to obtain a silver phosphate film. Finally, sinter at 550°C for 2 hours to obtain silver phosphate Ag with good binding force. 3 PO 4 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com