Magnetorheological polishing method and polishing tool

A technology of magnetorheological polishing and electromagnet, which is applied in the application of new intelligent materials, magnetorheological polishing methods and polishing tools, can solve the problems of complex magnetic field calculation and unsatisfactory polishing effect, and achieve precise control, simple structure, Make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

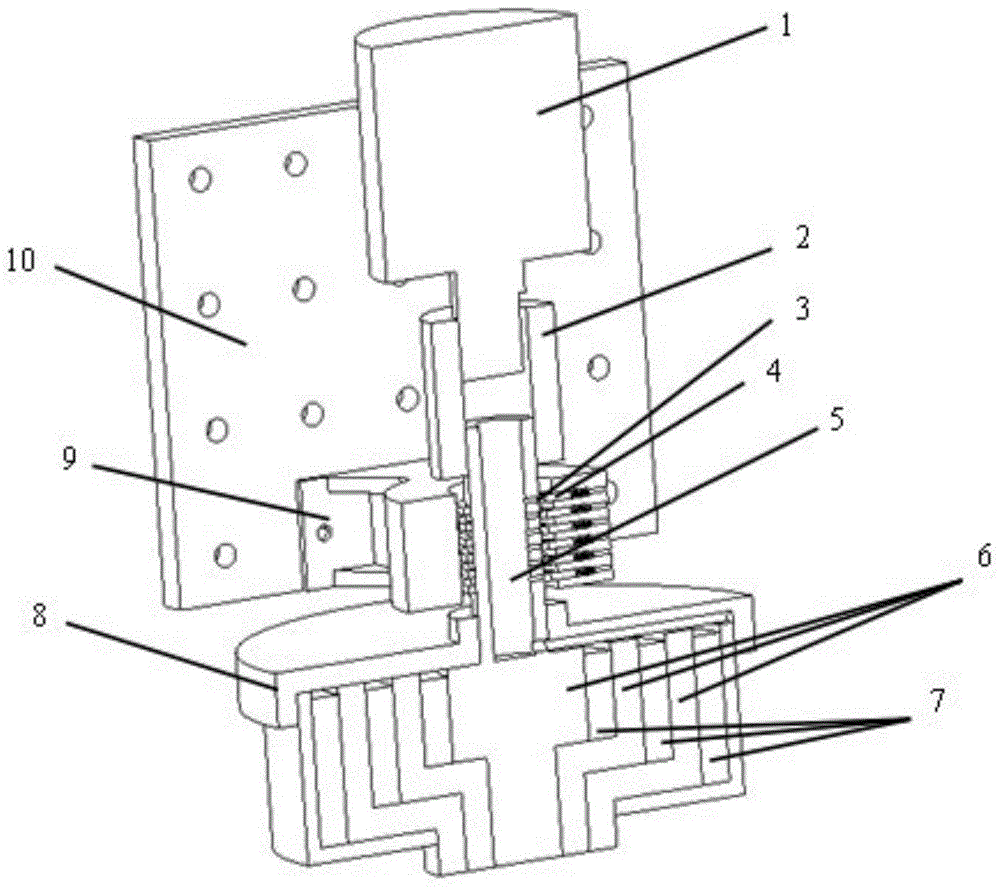

[0032] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments,

[0033] A magnetorheological polishing method, specifically comprising the steps of:

[0034] Step 1. The surface information of the workpiece is known;

[0035] Step 2. Determine the position of the polishing tool and the polishing gap;

[0036] Step 3, inject magnetorheological fluid into the polishing gap;

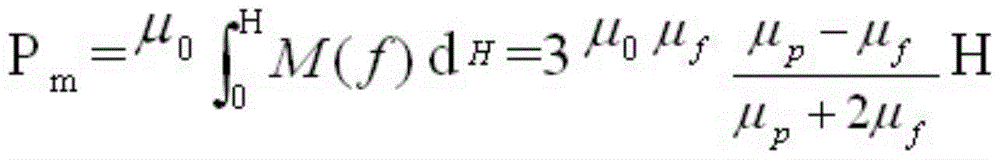

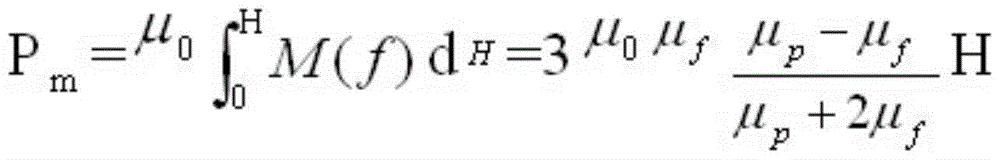

[0037] Step 4, calculate the polishing pressure distribution when the uniform removal rate is obtained from the surface shape information of the polishing area and the linear velocity distribution of each point in the polishing area;

[0038] It is known that the polishing speed ν=ωr in the plane polishing, the polishing speed distribution in the radial direction of the polished area, the linear speed at the center of the circle is the lowest, the linear speed increases gradually along the radial direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com