Preparation method of chiral dimethyl cyclopropyl carboxamide

A technology of dimethyl cyclopropanecarboxamide and dimethyl cyclopropanecarboxylate is applied in the preparation of chiral dimethyl cyclopropanecarboxamide compounds, in the field of dimethyl cyclopropanecarboxamide, and can solve the problem of high cost, Problems such as low yield of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

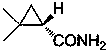

[0026]

[0027] The preparation method of above-mentioned a kind of (S)-ethyl dimethylcyclopropanecarboxylate specifically comprises the steps:

[0028] In a 1000 mL three-necked flask equipped with a thermometer and a dropping funnel, add (R,R)-(+)-2,2'-isopropylidenebis(4-tert-butyl-2-oxazoline) ( 1.74 g, 5.94 mmol), cuprous trifluoromethanesulfonate (1.14 g, 5.4 mmol) and dichloromethane (250 mL) were stirred at room temperature (25~30 ℃) for 2 h. Cool the reaction system to -5~0°C, add isobutylene to saturation, then slowly add ethyl diazoacetate (114 g, 1 mol) dropwise, control the temperature of the reaction system at 0°C, and slowly warm up to room temperature (25 ℃), continue to stir and react for 1 h; after the completion of the EDA reaction by TLC, the system is concentrated under reduced pressure (T 98 %, e.e. >95%.

Embodiment 2

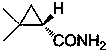

[0030]

[0031] Above-mentioned a kind of (S)-dimethyl cyclopropanecarboxylate preparation method specifically comprises the steps:

[0032] In a 1000 mL three-necked flask equipped with a thermometer and a dropping funnel, add (R,R)-(+)-2,2'-isopropylidenebis(4-tert-butyl-2-oxazoline) ( 1.74 g, 5.94 mmol), cuprous trifluoromethanesulfonate (1.14 g, 5.4 mmol) and dichloromethane (250 mL) were stirred at room temperature (25~30 ℃) for 2 h. Cool the reaction system to -5~0°C, add isobutylene to saturation, then slowly add isopropyl diazoacetate (129 g, 1 mol) dropwise, control the temperature of the reaction system at 0°C, and slowly warm up to room temperature after the addition ( 25 ℃), continue to stir the reaction for 1 h; after the completion of the EDA reaction by TLC, the system is concentrated under reduced pressure (T 98 %, e.e. Value >95%.

Embodiment 3

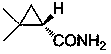

[0034]

[0035] The preparation method of above-mentioned a kind of (S)-dimethylcyclopropanecarboxylate, specifically comprises the steps:

[0036] In a 1000 mL three-necked flask equipped with a thermometer and a dropping funnel, add (R,R)-(+)-2,2'-isopropylidenebis(4-tert-butyl-2-oxazoline) ( 1.74 g, 5.94 mmol), cuprous trifluoromethanesulfonate (1.14 g, 5.4 mmol) and dichloromethane (250 mL) were stirred at room temperature (25~30 ℃) for 2 h. Cool the reaction system to -5~0°C, add isobutylene to saturation, then slowly add the above-prepared methyl diazoacetate (101 g, 1 mol) dropwise, control the temperature of the reaction system to 0°C, and slowly heat up the system after the addition After reaching room temperature (25 ℃), continue to stir and react for 1 h; after the EDA reaction is complete by TLC, the system is concentrated under reduced pressure (T 98 %, e.e. values >95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com