Wire insulation layer composition with scraping resistance, and preparation method and wire thereof

A composition and insulating layer technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve problems such as insufficient scratch resistance, improve scratch resistance, good scratch resistance, and reduce friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

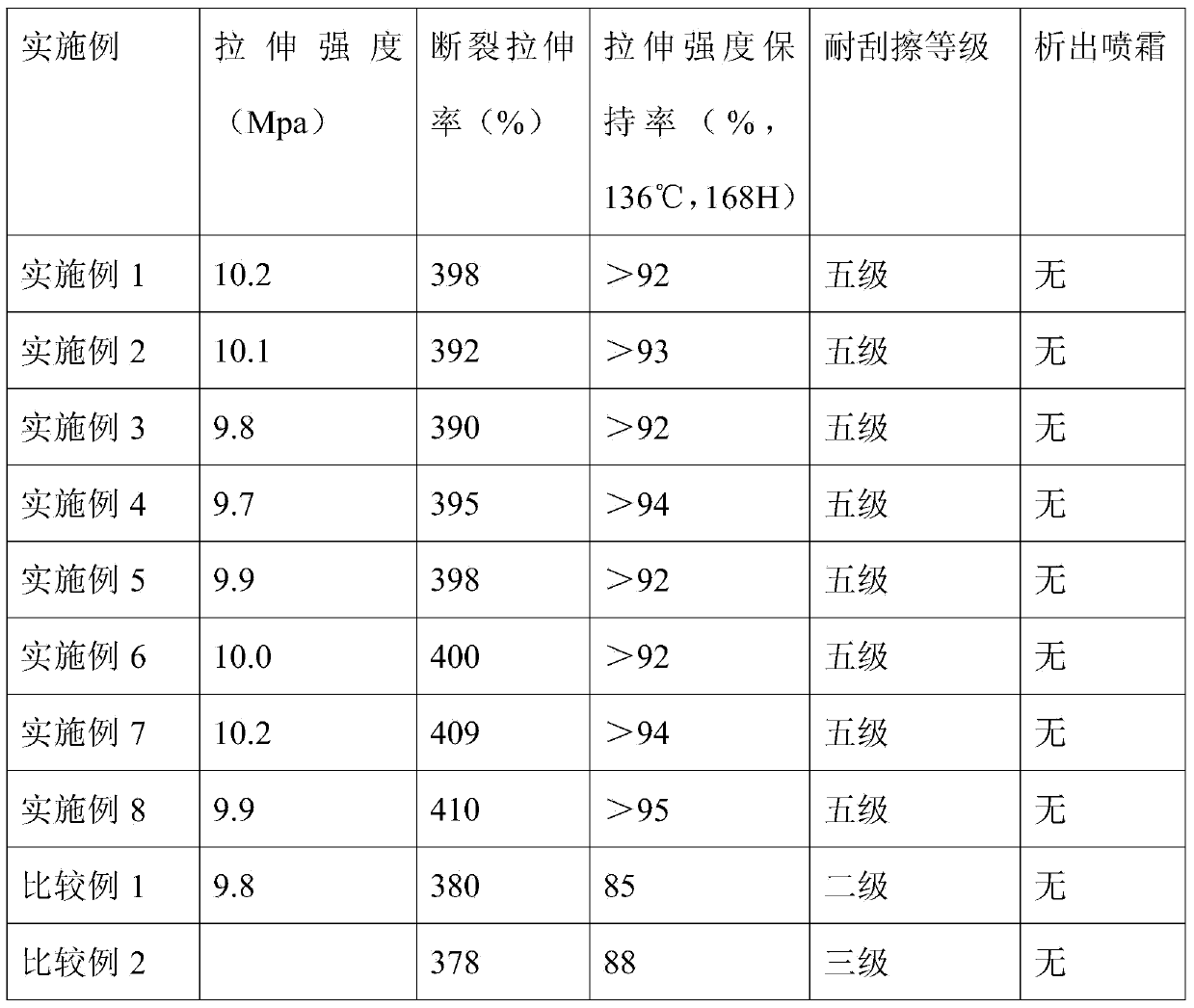

Examples

Embodiment 1

[0030] 70 parts by weight of polypropylene, 60 parts by weight of styrene-butadiene-styrene copolymer, 50 parts by weight of calcium carbonate, 1 part by weight of SEBS-MAH, 30 parts by weight of decabromodiphenylethane, pentaerythritol stearate 1 part by weight and 1 part by weight of erucamide are added to a high-mixer for premixing, the mixing temperature is 20°C, the rotation speed is 800rpm, and the mixing time is 2 minutes; the premixed materials are added to a twin-screw extruder, melt-melt extruded For granulation, the temperature of each section of the twin-screw extruder was 185° C. during extrusion, and the screw speed was 500 rpm.

Embodiment 2

[0032] 75 parts by weight of polypropylene, 62 parts by weight of styrene-ethylene-butylene-styrene copolymer, 55 parts by weight of talc, 1.5 parts by weight of SEBS-MAH, 33 parts by weight of 1,2-bis(tribromophenoxy)ethane Parts by weight, 1.5 parts by weight of polyethylene wax and 1.4 parts by weight of oleic acid amide are added to a high-mixer for premixing, the mixing temperature is 35°C, the rotating speed is 120rpm, and the mixing time is 20 minutes; the premixed materials are added to the twin-screw The extruder is used for melt extrusion and granulation. During extrusion, the temperature of each section of the twin-screw extruder is 190° C., and the screw speed is 400 rpm.

Embodiment 3

[0034] 78 parts by weight of polypropylene, 68 parts by weight of styrene-butadiene-styrene copolymer, 56 parts by weight of kaolin, 2 parts by weight of SEBS-MAH, 32 parts by weight of tetrabromobisphenol A, 1.5 parts by weight of polyethylene wax and Add 1.5 parts by weight of oleic acid amide into a high-mixer for premixing, the mixing temperature is 30°C, the rotation speed is 500rpm, and the mixing time is 10 minutes; the premixed materials are added to a twin-screw extruder, melted and extruded to granulate, During extrusion, the temperature of each section of the twin-screw extruder was 215° C., and the screw speed was 300 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com