Novel modified titanium dioxide white antirust pigment and preparing method thereof

A technology of titanium dioxide and anti-rust pigments, applied in chemical instruments and methods, anti-corrosion coatings, inorganic pigment treatment, etc., can solve the problems of chemical bond energy breakage, chemical degradation, overall performance decline, and high photochemical activity, so as to improve the surface state and improve anti-corrosion. performance, the effect of improving stability and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

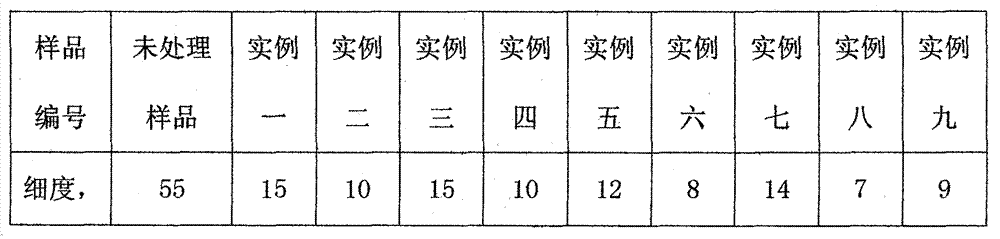

Examples

example 1

[0020] Adopting 60 kilograms of crude titanium dioxide without surface treatment, adding 40 kilograms of deionized water to make a slurry with a concentration of 60%, adding 0.48 kilograms of PAM-100, 1 kilogram of methyltrimethoxysilane and 0.30 kilograms of triethanolamine, Use a disperser to disperse at a high speed at 1500 rpm to make it fully mixed and even. After the mixed powder was dried, it was anaerobically calcined at 300° C. for 3 hours, then cooled and pulverized to obtain 61 kg of highly effective anti-corrosion and easy-to-disperse white pigment.

example 2

[0022] Use 70 kg of crude titanium dioxide without surface treatment, add 30 kg of deionized water to make a slurry with a concentration of 70%, add 1 kg of PAM-100, 0.5 kg of γ-methacryloxypropyl trimethoxy Silane and 0.20 kg of triethanolamine are dispersed at a high speed by a disperser at 1500 rpm to fully mix them evenly. After the mixed powder was dried, it was anaerobically calcined at 320° C. for 3 hours, then cooled and pulverized to obtain 71 kg of high-efficiency anti-corrosion and easy-to-disperse white pigment.

example 3

[0024] Use 80 kg of crude titanium dioxide without surface treatment, add 20 kg of deionized water to make a slurry with a concentration of 80%, add 0.8 kg of PAM-100, 0.5 kg of γ-methacryloxypropyl trimethoxy Silane and 0.30 kg of triethanolamine are dispersed at a high speed by a disperser at 1500 rpm to fully mix them evenly. After the mixed powder was dried, it was anaerobically calcined at 320° C. for 3 hours, and then cooled and pulverized to obtain 81 kg of highly effective anti-corrosion and easy-to-disperse white pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com