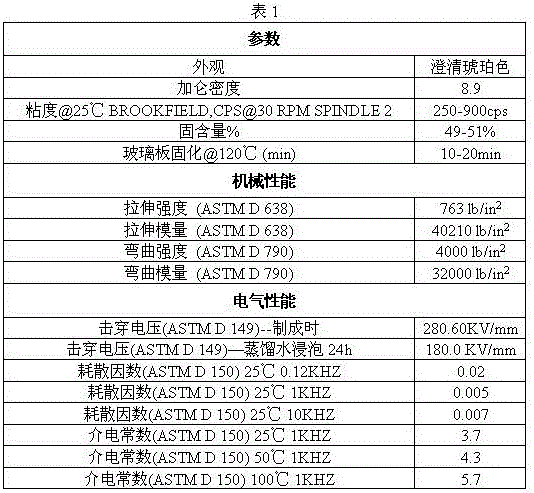

A kind of low-temperature fast-curing water-based impregnated insulating varnish and preparation method thereof

A rapid curing, impregnating insulation technology, applied in coatings, polyester coatings, etc., can solve the problems of increased resin molecular weight, limited amount of phenolic resin, and muddy paint, and achieves improved mechanical strength, rapid low-temperature curing, and improved weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

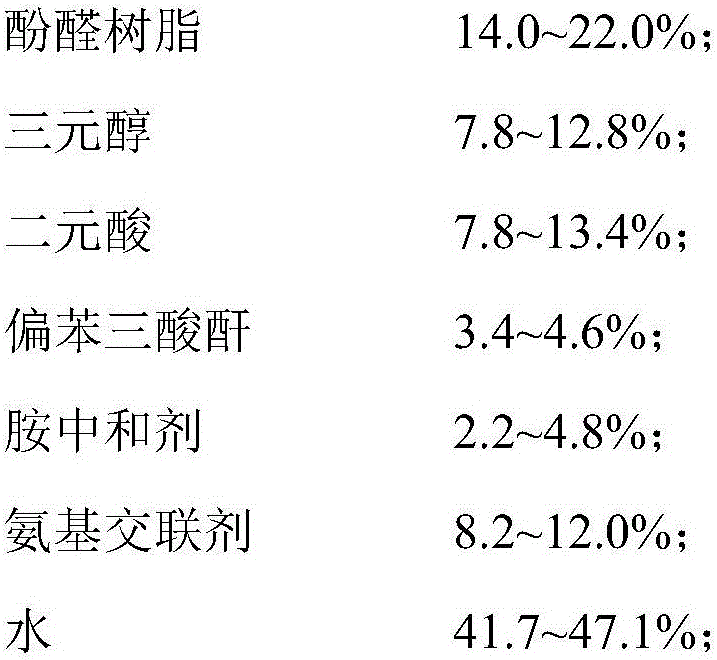

Method used

Image

Examples

Embodiment 1

[0035] A: Preparation of phenolic resin:

[0036] In parts by weight, take 100 parts of phenol, 30 parts of paraformaldehyde, and 1.2 parts of triethylamine into the first reaction kettle, start stirring, and heat up to 130°C for condensation reaction; test the viscosity of the reactant until the viscosity reaches 1200~ 1500cps@80℃, cool down, end. Take it out from the first reaction kettle and set it aside.

[0037] B: Synthetic product of the present invention by the phenolic resin that step A makes

[0038] Take 100 parts of the above-mentioned phenolic resin, 58 parts of glycerin, 40 parts of isophthalic acid, and 10 parts of adipic acid and add them to the second reaction kettle, start stirring, raise the temperature to 230 ° C, and test the acid value of the reactant until the acid value is lower than 10mgKOH / g, lower the temperature to 160°C, add 18 parts of trimellitic anhydride, keep the kettle temperature at 160°C, test the acid value of the reactant until the acid...

Embodiment 2

[0040] A: Preparation of phenolic resin:

[0041] In parts by weight, add 100 parts of xylenol, 20 parts of paraformaldehyde, and 1.5 parts of triethylamine into the first reaction kettle, start stirring, and heat up to 130°C for condensation reaction; test the viscosity of the reactant until the viscosity reaches 1200~1500cps@80℃, cool down, end. Take it out from the first reaction kettle and set it aside.

[0042] B: Synthetic product of the present invention by the phenolic resin that step A makes

[0043] Take 100 parts of the above-mentioned phenolic resin, 42 parts of trimethylolpropane, 20 parts of glycerin, 40 parts of isophthalic acid, and 22 parts of adipic acid and add them to the second reaction kettle, start stirring, and raise the temperature to 230 ° C to test the reactants. Acid value, until the acid value is lower than 10mgKOH / g, lower the temperature to 160°C, add 24 parts of trimellitic anhydride, keep the kettle temperature at 160°C, test the acid value o...

Embodiment 3

[0045] A: Preparation of phenolic resin:

[0046] In parts by weight, take 100 parts of phenol, 40 parts of paraformaldehyde, and 3.0 parts of dimethylethanolamine and add them to the first reaction kettle, start stirring, and heat up to 130°C for condensation reaction; test the viscosity of the reactant until the viscosity reaches 1200 ~1500cps@80℃, cool down, end. Take it out from the first reaction kettle and set it aside.

[0047] B: Synthetic product of the present invention by the phenolic resin that step A makes

[0048]Take 100 parts of the above-mentioned phenolic resin, 80 parts of trimethylolethane, 50 parts of isophthalic acid, and 20 parts of adipic acid and add them to the second reaction kettle, start stirring, raise the temperature to 230 ° C, and test the acid value of the reactants. Until the acid value is lower than 10mgKOH / g, lower the temperature to 160°C, add 28 parts of trimellitic anhydride, keep the kettle temperature at 160°C, test the acid value of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com