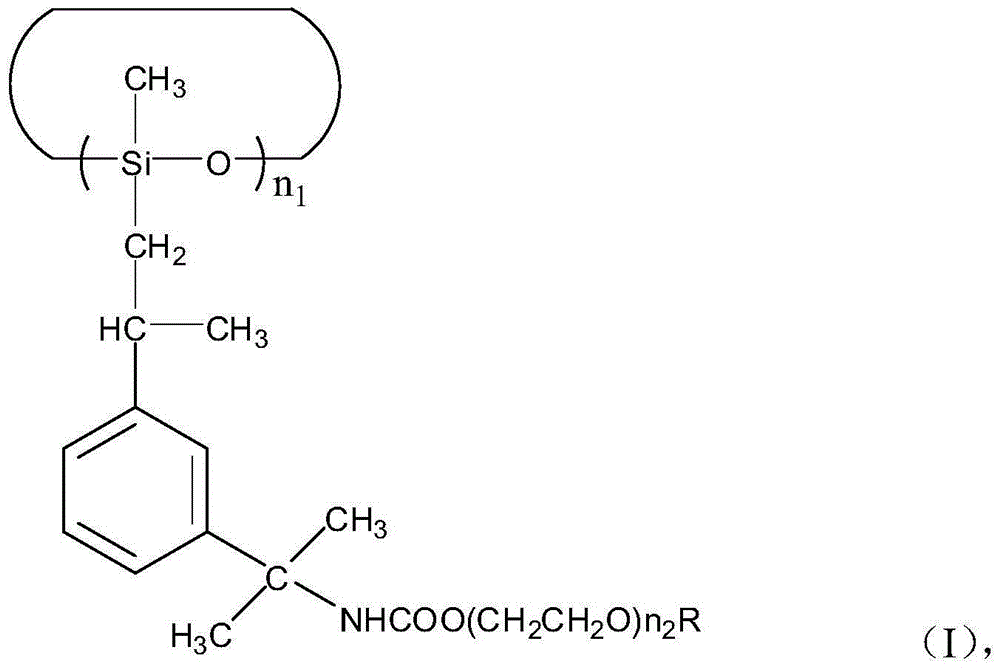

A kind of removable water-based acrylate pressure-sensitive adhesive and its preparation method and application

A water-based acrylate, pressure-sensitive adhesive technology, applied in the directions of ester copolymer adhesives, adhesive types, adhesive additives, etc., can solve the problems of insufficient cohesion, insufficient adhesion, residual glue, etc. Rheological stability, enhanced stability, improved adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

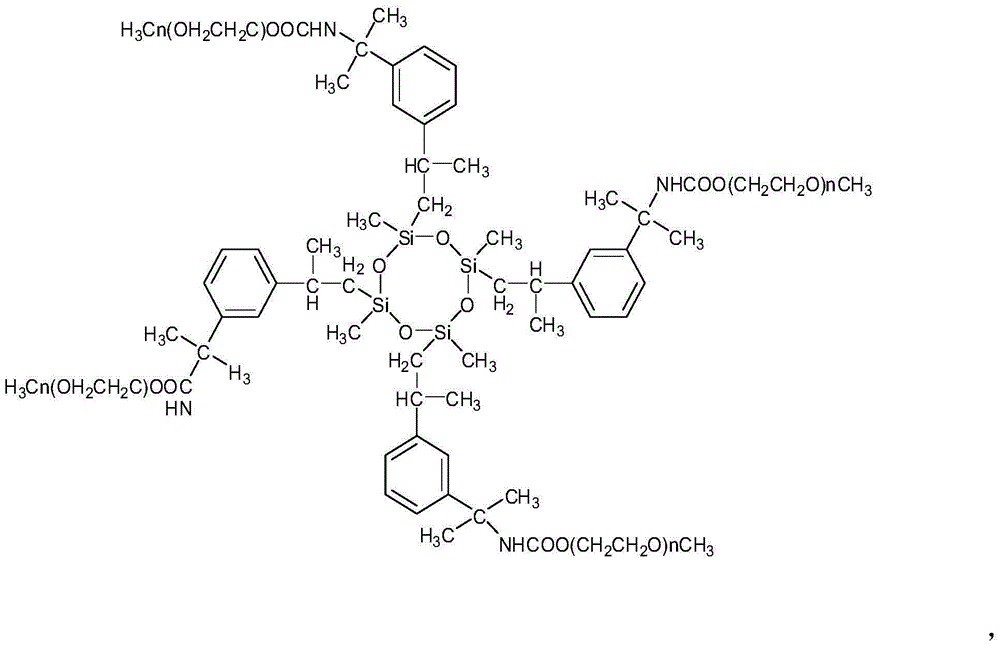

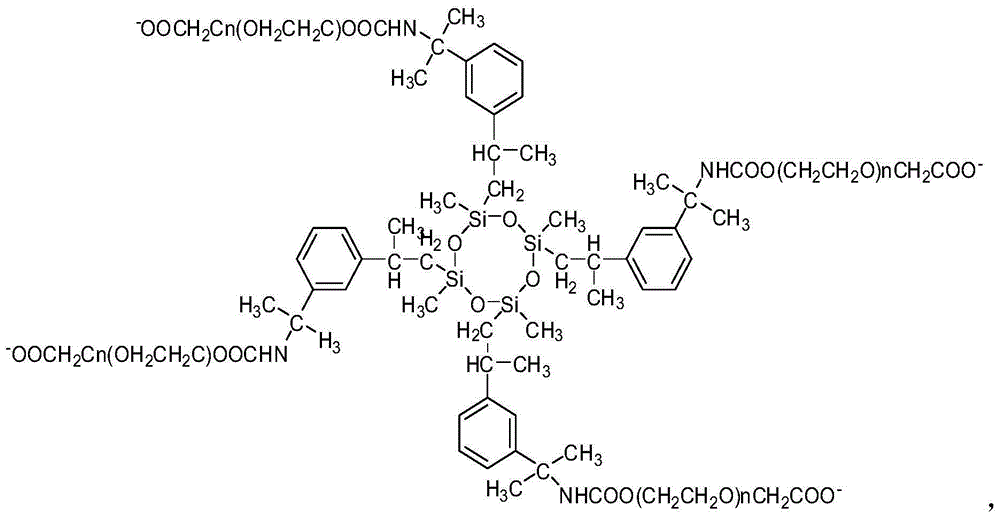

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the present invention is:

[0055] a. Pre-emulsification: Mix and dissolve the anionic emulsifier in component 1 with water, stir fully and heat to 60±5°C to dissolve, and add soft monomer, hard monomer and functional monomer in turn under stirring, The stirring time is controlled at 25-35 minutes to prepare the pre-emulsion. During the stirring period, the stirring speed is slowly increased to 500 rpm;

[0056] b. Emulsion polymerization: Add component 2 into the reactor, heat to raise the temperature to 82±2°C, and half an hour after the blue light appears in the reactor, add the pre-emulsion prepared in step a dropwise, and control the dripping for 3 hours , then add component 3, and keep the temperature at 86±2°C for 1 hour to form a semi-finished product;

[0057] c. Blending: Stop heating the semi-finished product obtained in step b. When the temperature drops to 40-50°C, adjust the pH value to 9 with the pH regulator in component 1, add...

Embodiment 1a

[0091] Embodiment 1a: Component 1-4 and preparation implementation method are the same as Comparative Example 1, in the preparation c step of pressure-sensitive adhesive, add component 5 multi-component star polymer (II) 1.0 together with component 4 share.

Embodiment 1b

[0092] Example 1b: Components 1-4 and preparation implementation method are the same as Comparative Example 2, in the preparation c step of pressure-sensitive adhesive, add component 5 multi-component star polymer (II) 5.0 together with component 4 share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com